Synthesis of Magnetic Carbonaceous Solid Acid and Base from Jatropha Hulls for the Production of Jatropha Biodiesel

Synthesis of Magnetic Carbonaceous Solid Acid and Base from Jatropha Hulls for the Production of Jatropha Biodiesel

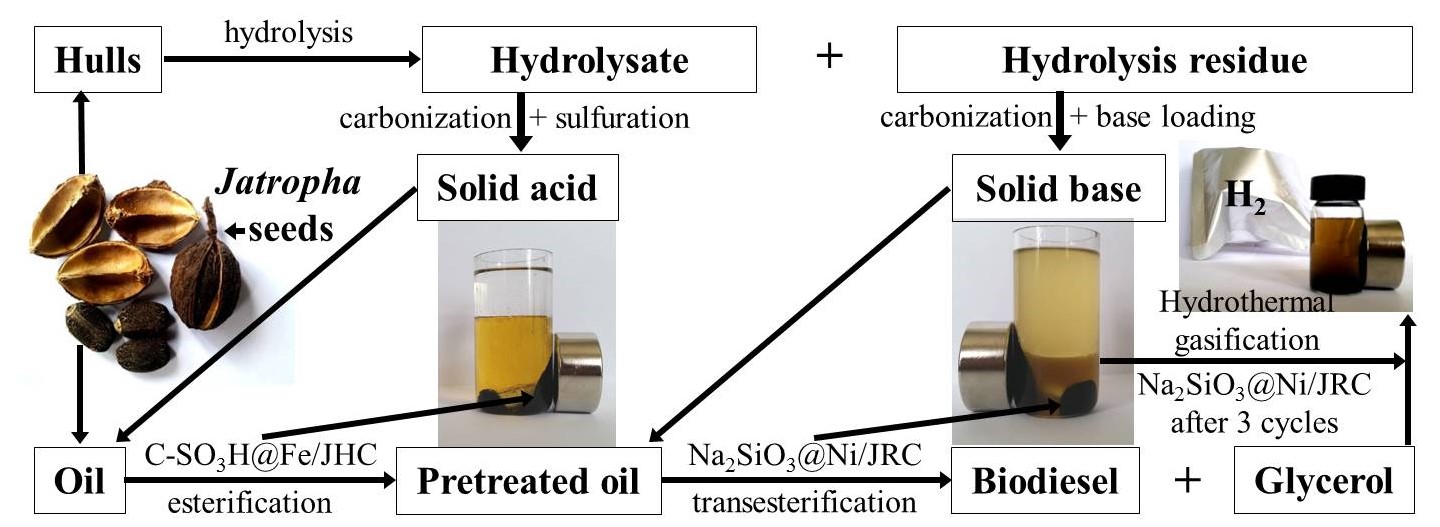

Jatropha seeds were extracted oil for biodiesel production and the hulls were carbonized to load active sites as magnetic carbonaceous solid acid and base catalysts. Crude Jatropha oil was esterified to decrease its acid value to 1.3 from 17.2 mg KOH/g by the solid acid, and subsequently transesterified to biodiesel (96.7% yield) catalyzed by the solid base. After 3 cycles and magnetically separated, the deactivated base was catalyzed the hydrothermal gasification of biodiesel by-product (crude glycerol) with gasification rate of 81% and 82% H2 purity.

Recently, biomass group synthesized magnetic carbonaceous solid acid (C-SO3H@Fe/JHC) and base (Na2SiO3@Ni/JRC) catalysts by loading active groups on the carbonaceous supporters derived from Jatropha-hull hydrolysate and hydrolysis residue. Characterization of their morphology, magnetic saturation, functional groups and total acid/base contents were performed by various techniques. Additional acidic functional groups that formed with Jatropha-hull hydrolysate contributed to the high acidity of C-SO3H@Fe/JHC catalyst for the pretreatment (esterification) of crude Jatropha oil with high acid values (AV). The AV of esterified Jatropha oil dropped down from 17.2 to 1.3 mg KOH/g, achieving a high biodiesel yield of 96.7% after subsequent transesterification reaction with Na2SiO3@Ni/JRC base that was cycled at least 3 times with little loss of catalysis activity. Both solid acid and base catalysts were easily recovered by magnetic force with average recovery yields of 90.3 wt% and 86.7%, respectively. After washed by ethanol, the catalysts were cycled for 10 times. The AV of esterified oil and biodiesel yield using the recycled catalysts remained below 2.0 mg KOH/g and above 85%, respectively. The existence of catalyst ions and residual methanol contributed to high H2 yield (81.0%) and high purity (81.7%) in the hydrothermal gasification of glycerol by-product using the deactivated solid base.

The results were published:

F Zhang, XF Tian, Zhen Fang*, M Shah, YT Wang, W Jiang, M Yao, Catalytic Production of Jatropha Biodiesel and Hydrogen with Magnetic Carbonaceous Acid and Base Synthesized from Jatropha Hulls, Energy Conversion and Management, 142, 107–116 (2017).

————————————————-

小桐子壳合成磁性固体酸和碱催化剂及用以生产小桐子生物柴油和氢气

最近,生物能源组通过对小桐子壳水解液和水解残渣合成的磁性碳载体加载活性基团,合成磁性炭质固体酸 (C-SO3H@Fe/JHC)和碱(Na2SiO3@Ni/JRC)催化剂。通过各种测试技术对其形态、磁性饱和度、功能基团和总酸/碱含量进行表征。小桐子壳水解液形成的酸性官能团有助于其负载的催化剂(C-SO3H@Fe/JHC)具备更高的酸密度,用于预处理(酯化)高酸值小桐子油, 酸值从17.2 降为 1.3 mg KOH/g。预处理后的小桐子油,在由小桐子壳水解残渣合成的碱性催化剂(Na2SiO3@Ni/JRC)作用下,通过脂交换反应,生物柴油产率可高达96.7%,该碱性催化剂可循环至少三次, 催化活性损失很少。固体酸和碱催化剂均可通过磁铁轻易地回收, 平均回收率为 90.3 wt% 和86.7%。用乙醇洗涤后, 催化剂可循环十次。使用回收的催化剂,预处理油的酸值低于2.0 mg KOH/g,生物柴油的产率高达85%以上。催化剂离子和残留的甲醇可用于进一步提高,用失活固体碱催化水热气化甘油副产品的氢气产量 (81.0%) 和纯度 (81.7%)。

结果发表在Energy Conversion and Management : F Zhang, XF Tian, Zhen Fang*, M Shah, YT Wang, W Jiang, M Yao, Catalytic Production of Jatropha Biodiesel and Hydrogen with Magnetic Carbonaceous Acid and Base Synthesized from Jatropha Hulls, Energy Conversion and Management, 142, 107–116 (2017)。