会议报告 Several plenary/keynote speeches were given

星期日, 17 9 月, 20231. Int’l Conf keynote国际会议大会/主旨报告:

Zhen Fang方真,“Porous biochar support for bifunctional catalysts for One-pot production of biodiesel from waste oils”,Frontier in Chemical Engineering, 15th Global Chinese Chemical Engineers Symp. (GCCES-2023), Hong Kong University of Science and Technology, Hong Kong, China, August 5-9, 2023 (香港科技大学,中国香港)Keynote Talks(主旨报告);

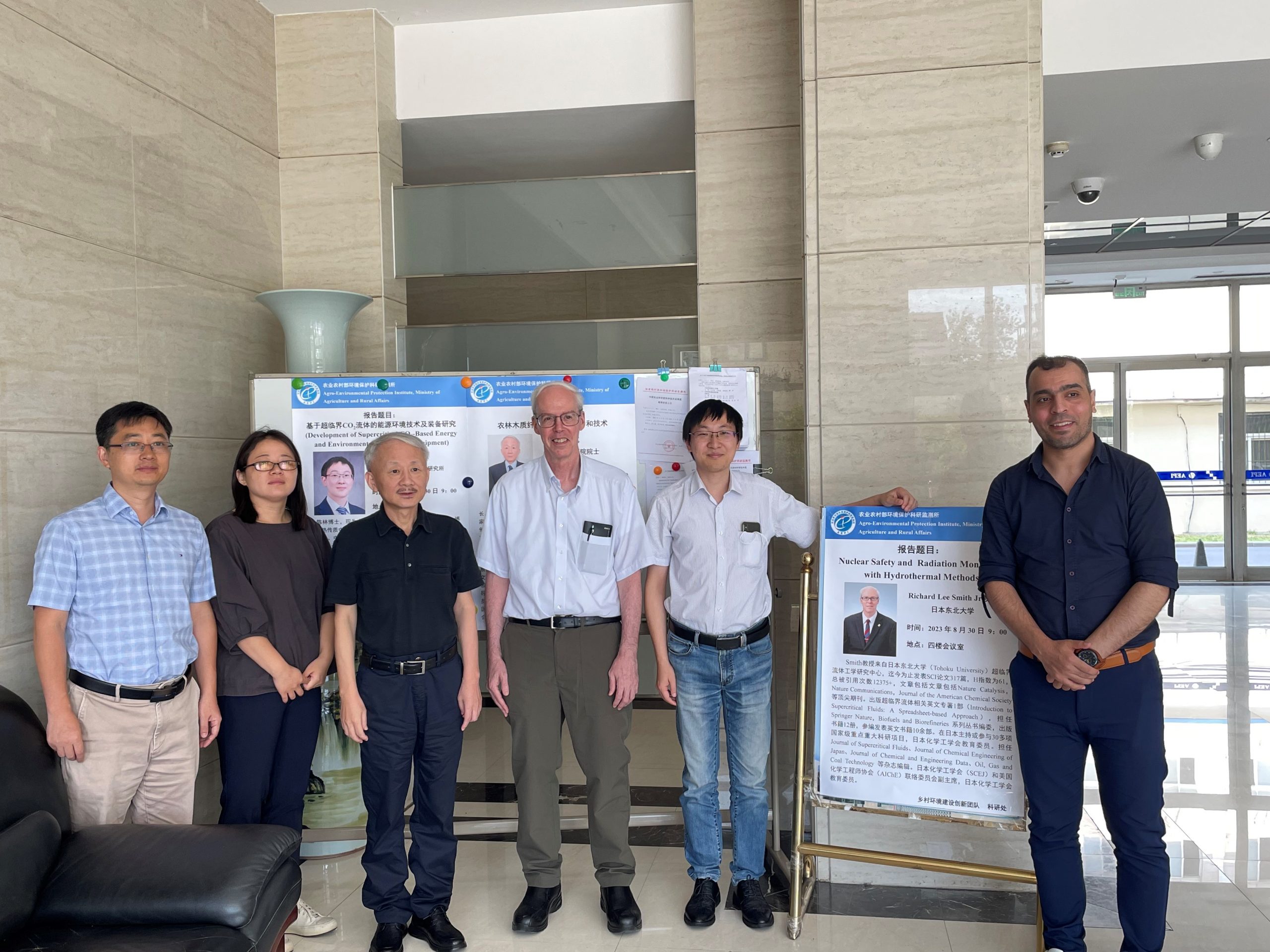

2.方真,“农林木质纤维素高值化应用和技术High value applications and techniques of agricultural and forestry lignocellulosic wastes”, 日本东北大学校友报告会,中国农科院天津环保所(特邀报告)2023年8月30日 (天津);

Zhen Fang, “High value applications and technologies of agricultural and forestry lignocellulosic wastes”, Alumni Report Association of Tohoku University, Tianjin Institute of Environmental Protection, Chinese Academy of Agricultural Sciences (invited speech), August 30, 2023 (Tianjin);

3.方真,“木质纤维素高值化应用和技术” 第35届全国糖业质量工作会议科技论坛 (大会报告),2023年8月22-24日 国家糖业质量检验检测中心(宁夏∙银川);2023年8月22-24日 国家糖业质量检验检测中心(宁夏∙银川)(大会报告);

Zhen Fang, “High Value Application and Technology of Lignocellulose”, Science and Technology Forum of the 35th National Sugar Industry Quality Work Conference (Plenary speech), August 22-24, 2023, National Sugar Industry Quality Inspection and Testing Center (Ningxia Yinchuan); August 22-24, 2023, National Sugar Industry Quality Inspection and Testing Center (Ningxia Yinchuan) (Plenary speech);

4.方真,“生物质和生物炼制Biomass & Bio-refineries” 科技咖啡馆 之 科学向光而行 科技自强自立2023年5月30日 江苏省科学技术协会 江苏∙南京(特邀报告);

Zhen Fang, “Biomass and Biorefineries” Technology Cafe: Science Strives for Light and Technology Self-reliance. May 30, 2023, Jiangsu Science and Technology Association, Nanjing, Jiangsu Province (Special Invited Speech);

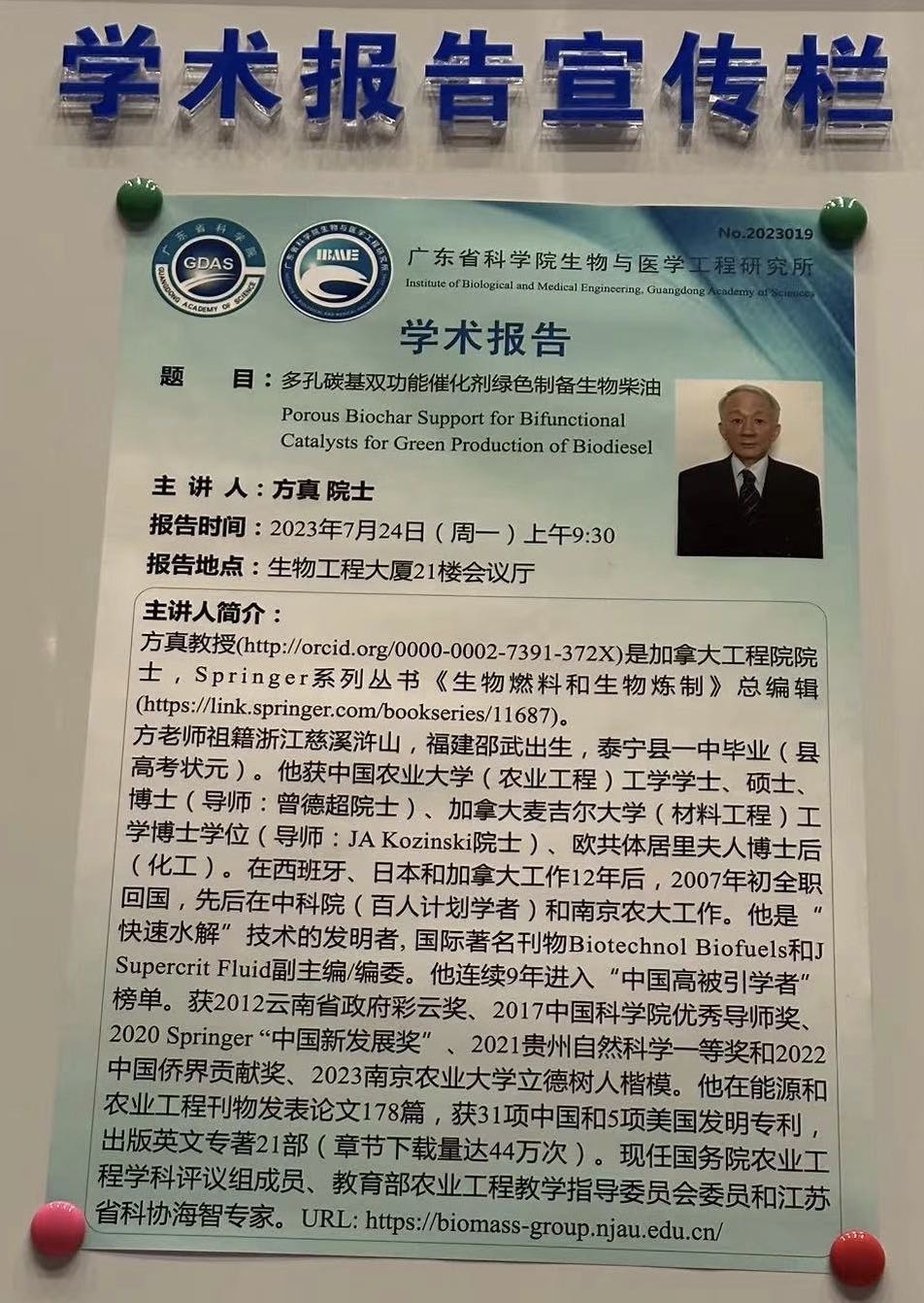

5.方真,“Porous biochar support for bifunctional catalysts for esterification & trans-esterification of waster oils”, 广东省科学院, 2023年07月24日 广州(特邀报告);

Zhen Fang, ” Porous biochar support for bifunctional catalysts for esterification & trans-esterification of waster oils”, Guangdong Academy of Sciences, July 24, 2023, Guangzhou (invited talk);

6.方真“生物质和生物炼制Biomass & Biorefineries” 2023安徽生物质能源技术创新和产业化发展高峰论坛, 中国农业工程学会,安徽农业大学,2023年07月08日 安徽∙合肥(特邀报告);

Zhen Fang “Biomass and Biorefining Biomass & Biorefineries” 2023 Anhui Biomass Energy Technology Innovation and Industrialization Development Summit Forum, Anhui Agricultural University, July 8, 2023, Anhui · Hefei (specially invited)

7.2023宁波·慈溪“上林峰会”开幕暨“智造人才友好城”建设启动2023.11.11. Ningbo Cixi “Shanglin Summit” Opening and “Smart Manufacturing Talent Friendly City” Construction Launching, Prof. Z Fang attended (Nov. 11, 2023)

8. 方真Zhen Fang “农林生物质转化为燃料和高附加值产品技术和应用 Techniques and applications of converting agricultural and forestry biomass to biofuels and high value-added products ” 2023 年(河南科技大学,特邀报告Henan University of Science and Technology, invited)2023年12月25日 河南∙洛阳);