碱颗粒球磨预处理: Efficient saccharification of wheat straw pretreated by solid particle-assisted ball milling with waste washing liquor recycling

星期日, 16 1 月, 2022碱颗粒球磨预处理: Efficient saccharification of wheat straw pretreated by solid particle-assisted ball milling with waste washing liquor recycling

Recently, PhD student Miss Xiao-le Liu supervised by Prof. Zhen Fang published a research article in Bioresource Technology about ball milling pretreatment with NaOH solid particles for enzymatic hydrolysis of wheat straw.

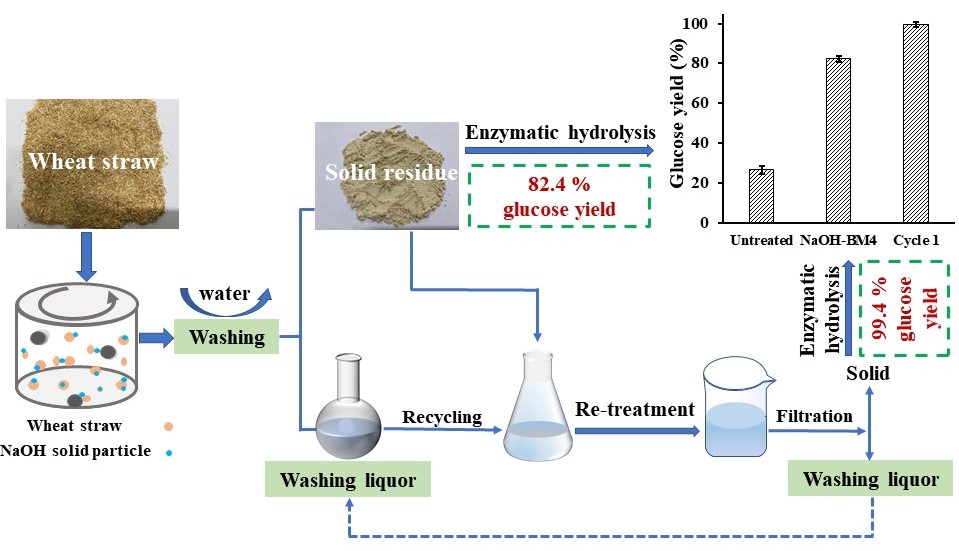

Wheat straw was pretreated using ball milling (BM) promoted by solid particles (NaOH, NaCl, citric acid). NaOH showed the best synergistic interaction effect, due to the breakage of β-1,4-glycosidic bonds among cellulose molecules by the alkali solid particles induced by BM. NaOH-BM pretreatment decreased the straw crystallinity from 46% to 21.4% and its average particle size from 398.3 to 50.6 μm in 1 h. After 4 h milling, the reducing-end concentration of cellulose increased by 3.8 times from 12.5 to 60.2 μM, with glucose yield increased by 2.1 times from 26.6% to 82.4% for 72 h enzymatic hydrolysis at cellulase loading of 15 FPU/g dry substrate. The pretreatment washing liquor was recycled for the re-treatment of partially pretreated biomass at 121 °C for 30 min, resulting in 99.4% glucose yield by enzymatic hydrolysis. BM assisted with alkali particles was an effective approach for improving biomass enzymatic saccharification.

Related results were published in Bioresource Technology:

XL Liu, CY Dong, SY Leu, Zhen Fang* (Supervisor), ZD Miao, Efficient Saccharification of Wheat Straw Pretreated by Solid Particle-Assisted Ball Milling with Waste Washing Liquor Recycling, Bioresource Technology, 347, 126721, https://doi.org/10.1016/j.biortech.2022.126721 (2022).

Wheat straw was ball milling pretreated with NaOH particles for 4 h with 82.4% glucose yield after 72 h enzymatic hydrolysis. The pretreatment washing liquor was recycled for the re-treatment of partially pretreated biomass at 121 °C for 30 min, resulting in 99.4% glucose yield. (球磨辅助NaOH颗粒预处理小麦秸秆4 h。酶水解72 h,预处理后小麦秸秆酶解率为82.4%。预处理后的水洗液循环利用,在121°C下,对预处理4 h后的小麦秸秆再预处理30 min,酶解率提高到99.4%)

球磨辅助固体颗粒预处理小麦秸秆的高效糖化及水洗废液的循环利用

最近,博士生刘小乐(女)在方真教授的指导下,在国际学术期刊Bioresource Technology (Q1, IF 9.6)发表一篇关于球磨辅助NaOH颗粒预处理小麦秸秆用于酶解的研究性论文。

通过球磨辅助固体颗粒(NaOH、NaCl,柠檬酸)预处理小麦秸秆。其中,球磨辅助NaOH颗粒预处理的协同作用最好,这可能是由于球磨可以使NaOH破坏纤维素分子间的β-1,4-糖苷键。球磨辅助NaOH颗粒预处理1 h后,纤维素结晶度从46%降为21.4%,平均粒径从398.3 μm降到50.6 μm。球磨辅助NaOH颗粒预处理4 h后,在15 FPU/g干底物的条件下酶解72 h,酶解率从26.6%提高到82.4%,酶解率较原始小麦秸秆提高2.1倍。对预处理后的水洗液进行循环利用,在121 ℃下对预处理4 h后的秸秆再预处理30 min,酶解率提高为99.4%。

结果发表在Bioresource Technology:

XL Liu, CY Dong, SY Leu, Zhen Fang* (Supervisor), ZD Miao, Efficient Saccharification of Wheat Straw Pretreated by Solid Particle-Assisted Ball Milling with Waste Washing Liquor Recycling, Bioresource Technology, 347, 126721, https://doi.org/10.1016/j.biortech.2022.126721 (2022).