院士讲座 “A Sustainable Bio-future Perspective” by JA Kozinski

25 7 月, 2025“A Sustainable Bio-future Perspective” by JA Kozinski

As invited by Prof. Zhen Fang based on the grant from the National Foreign Expert Bureau of China, Prof. Janusz A Kozinski (Dean of Engineering, Lakehead, Fellow of Canadian Academy of Engineering) as a distinguished visiting professor is jointly working with our group for two months from July to August in the biomass group, college of engineering at Nanjing Agricultural University (NJAU). On July 21, 2025 (13:30 pm – 4:30 pm), Prof. Kozinski gave a second lecture entitled “A Sustainable Bio-future Perspective” to our students and faculty members.

Prof. Kozinski is presenting his second lecture, Kozinski院士进行第二场演讲

In his lecture, Prof. Kozinski captivated the audience with an engaging presentation on the power of engineers and scientists in shaping the world. He emphasized the crucial role they play in creating everything that isn’t naturally occurring, as highlighted by the visual of a human hand reaching out to a robotic hand.

Human Creativity, 人类的创造力

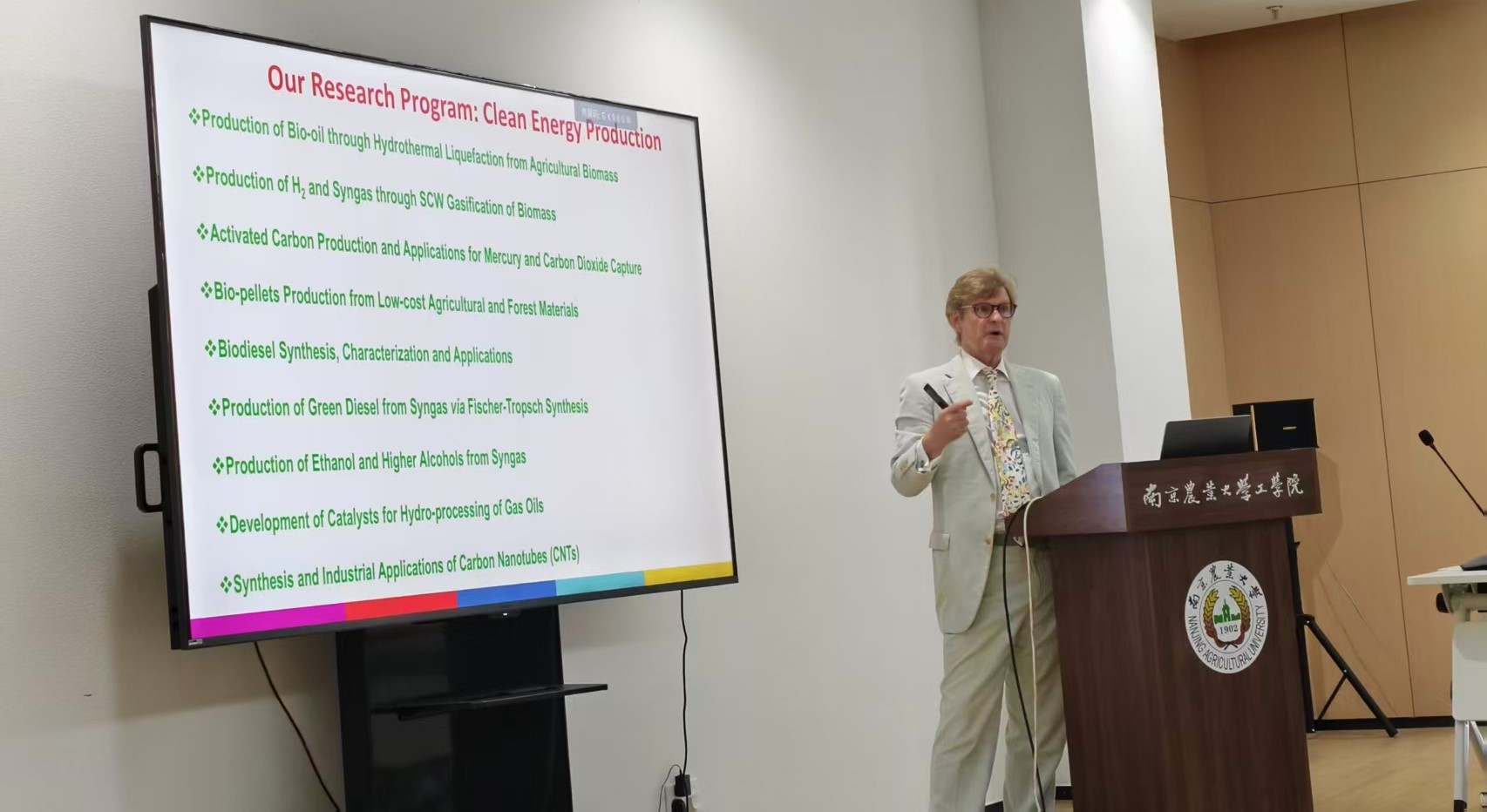

Prof. Kozinski also discussed critical global issues such as fossil fuel consumption, greenhouse gas emissions, and their impact on climate change. He presented compelling data on the leading contributors to greenhouse gas emissions, stressing the significant role of countries like China and the U.S. He further explored the increasing demand for energy, the depletion of resources, rising fuel prices, and the geopolitical issues that come with them. At the end of the lecture, Prof. Kozinski discussed the role of engineers in addressing these challenges, particularly in the context of renewable energy and sustainable solutions. He also presented detailed research on renewable energy conducted by his Canadian research group, which will collaborate with our Biomass Group at Nanjing Agricultural University to tackle key issues in bioenergy.

Global challenges in energy 地球面临的能源挑战

Prof. Kozinski’s research fields in bioenergy, Kozinski院士研究组的研究领域

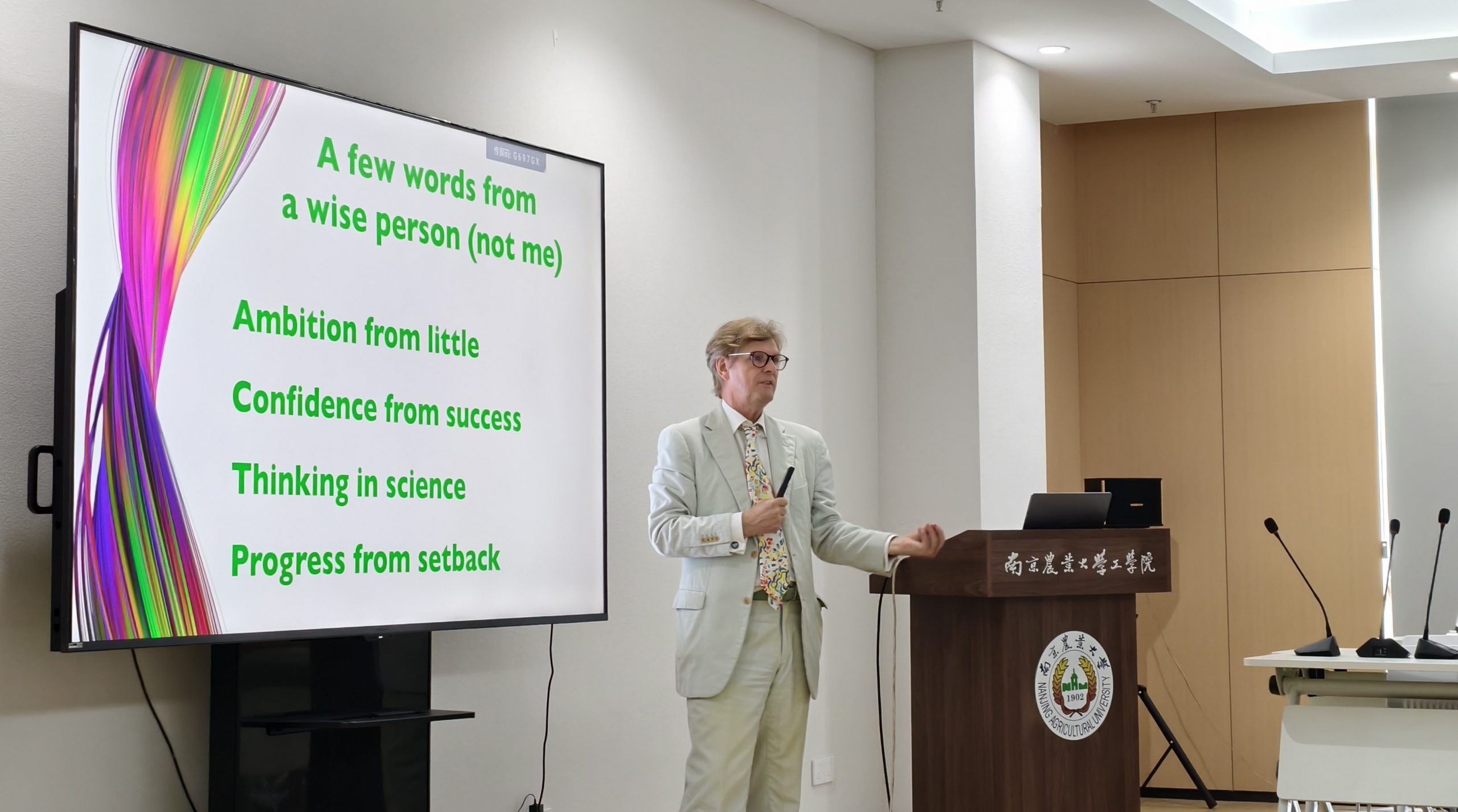

Giving a Motto to encourage young people, 以座右铭鼓励年轻人

After the lecture, students and faculty members engaged in a lively discussion, raising insightful questions on the future of energy and engineering as well as joint research projects and exchange plans between China and Canada.

Discussion with students, Kozinski院士与硕士留学生热烈讨论

Discussion with young faculty members, Kozinski院士与青年教师热烈讨论

Prof. Janusz A Kozinski, a world well-known scientist in renewable energy, is Fellow of Canadian Academy of Engineering and the Board member of the Academy, he severed as Associate Vice-principal of McGill, Founding President, Hereford University of Technology and Engineering (UK), Engineering Dean at U Saskatchewan and York. He received the Gold Medal in 2022 at the Ontario Professional Engineers Awards Gala and the 2023 Gold Medal awarded by Engineers Canada, the highest honour for an engineer in Canada.

Prof. Zhen Fang summarizing the presentation, 方老师对演讲进行了总结

——————————————————————————————————–

Kozinski院士讲座 “可持续生物未来的前景”

应方真老师邀请,由中国国家外国专家局高端人才项目的资助,Janusz A Kozinski教授(加拿大工程院院士、湖首大学工学院院长)作为杰出的访问教授,于2025年7月至8月在南京农业大学生物质组工作2个月。2025年7月21日下午,Kozinski教授为我们的师生们做了第二场题为“可持续生物未来的前景”的特别讲座。

在他的讲座中,Kozinski教授通过生动的演示吸引了观众的注意力,强调了工程师和科学家在塑造世界中的关键作用。他指出,正是工程师和科学家创造了所有非自然存在的事物,正如那张展示人类手与机器人手相握的图像所传达的意义。Kozinski教授还讨论了全球面临的关键问题,如化石燃料的消耗、温室气体排放及其对气候变化的影响。他展示了关于主要温室气体排放者的有力数据,特别指出了中国和美国在这一问题中的重要地位。他进一步探讨了能源需求的增长、资源的枯竭、燃料价格的上涨以及随之而来的地缘政治问题。讲座最后,Kozinski教授讨论了工程师在应对这些挑战中的作用,特别是在可再生能源和可持续解决方案的背景下,他加拿大研究组在可再生能源中的详细研究,他们将与我们南京农业大学生物能源研究组共同合作解决生物能源方面关键问题。讲座结束后,师生们进行了热烈的讨论,提出了关于能源未来和工程学的深刻问题。

Discussion with students, Kozinski教授和与会者热烈讨论

Citing Prof. Zhen Fang’s words in the Speech of his Alma Mater Taining Experimental Primary School for his 50th Anniversary of Graduation to inspire students and young faculty members,引用方真老师毕业50周年给母校福建泰宁实验小学的赠言鼓励硕博生和年青教师

Janusz A. Kozinski院士是国际可再生能源领域权威学者,加拿大工程院院士和工程院理事会(主席团)成员,注册工程师,现任湖首大学工学院院长和教授,历任加拿大麦吉尔大学研究副校长助理、英国赫里福德科技工程大学校长、约克大学理工学院院长和工学院创建院长、萨斯喀彻温大学工学院院长等。他于2022年在安大略省专业工程师颁奖典礼上获得金牌,并于2023年获得加拿大工程师协会颁发的金牌,这是加拿大工程师的最高荣誉。