泰宁实小演讲My Experiences in Learning and Study – Taining, where my dream started

26 7 月, 2025

泰宁我梦想开始的地方, Taining, where my dream started

My Experiences in Learning and Study – Taining, where my dream started

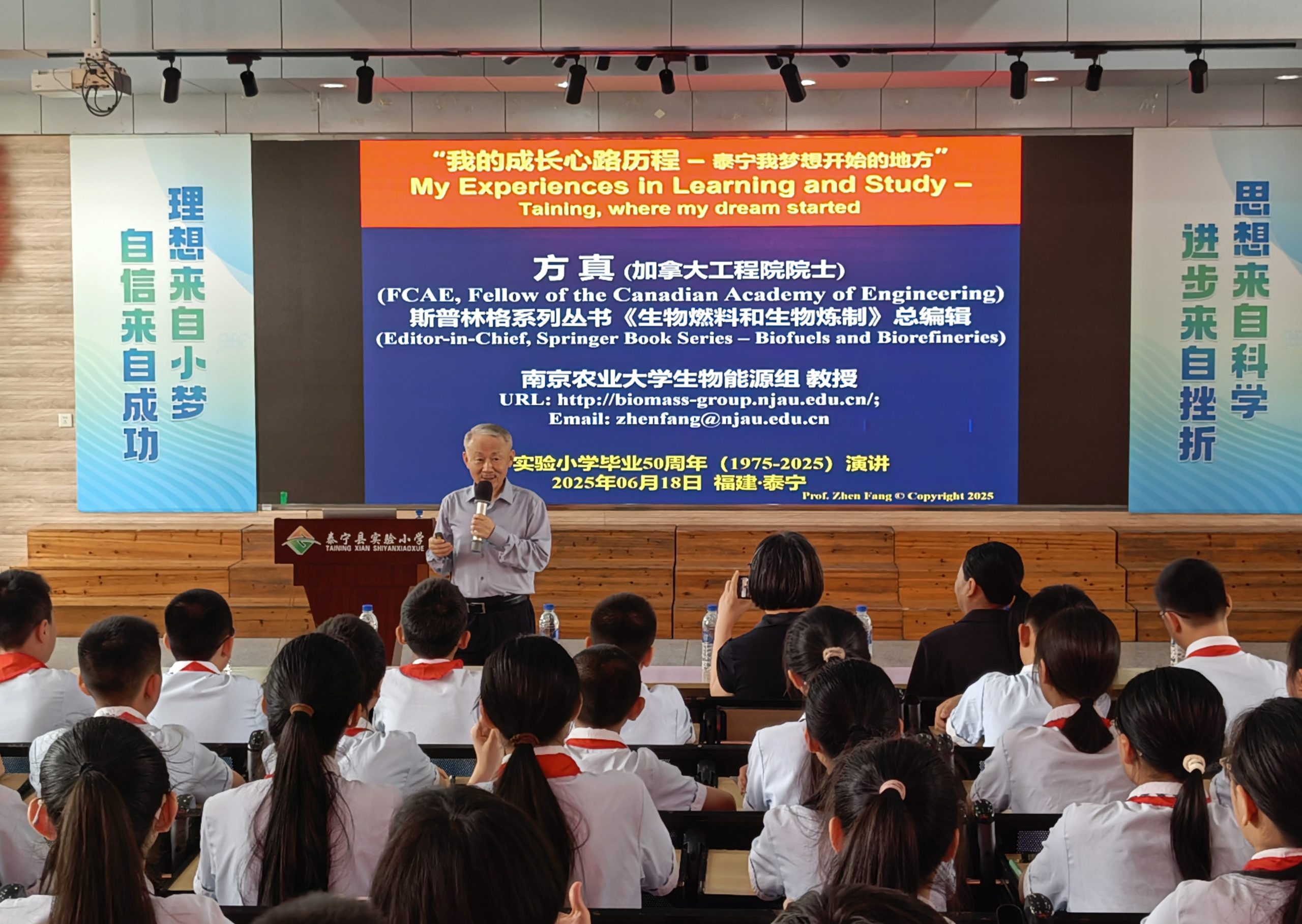

As invited by Principal Ms. Xie, in the morning of June 18th, 2025, Professor Zhen Fang (Fellow of Canadian Academy of Engineering) from Nanjing Agricultural University gave a lecture entitled “My Experiences in Learning and Study – Taining, where my dream started” to pupils of Alma Mater Taining Experimental Primary School for his 50th Anniversary of Graduation (1975-2025). Taining Experimental Primary School was founded in 1905, officially named “Experimental Primary School” in 1953, and designated as a Fujian provincial key primary school in 1979. There are currently over 1800 students and 77 faculty members.

方真老师演讲Prof. Zhen Fang‘s speech

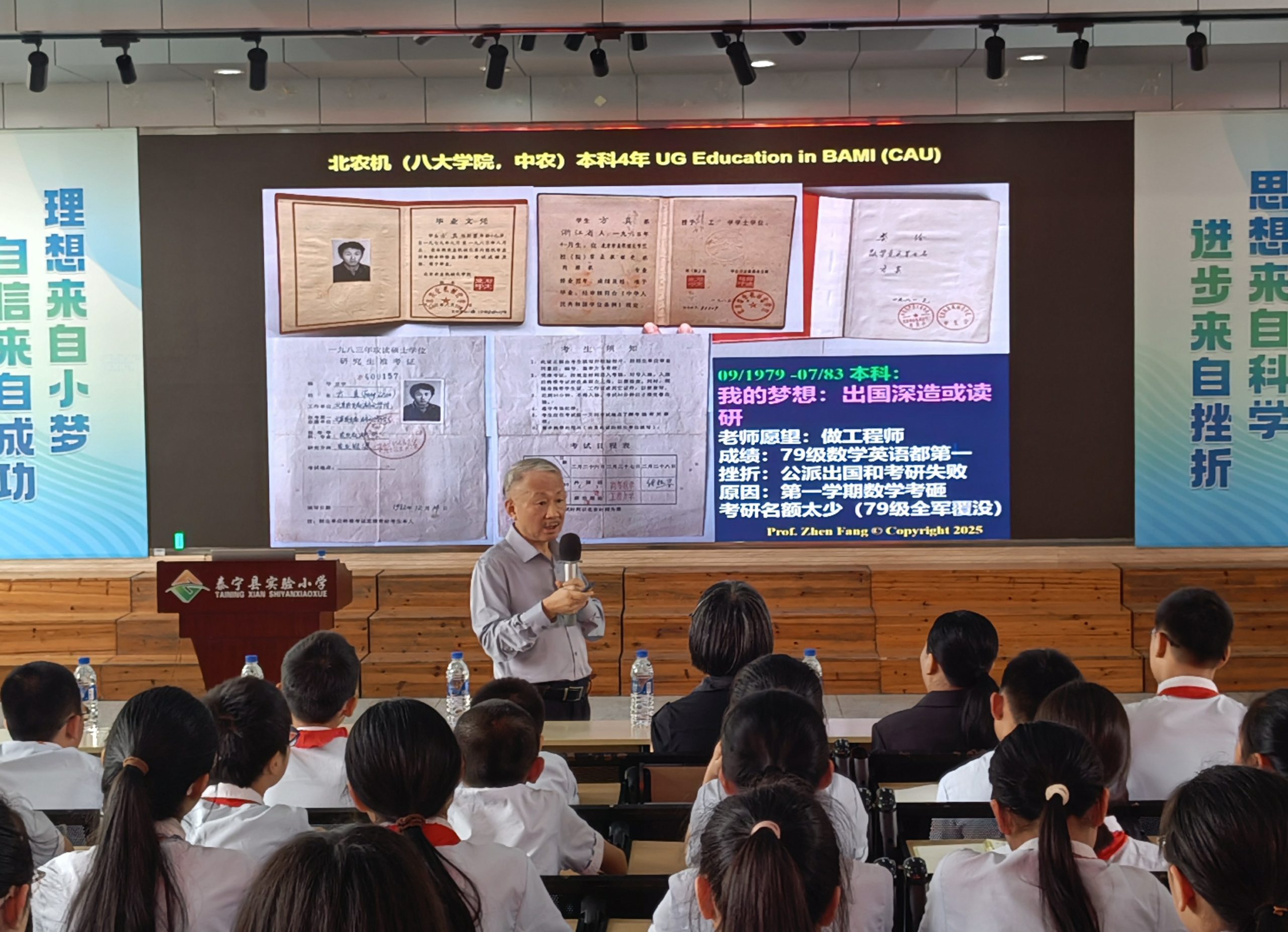

In the lecture, Professor Zhen Fang deeply recalled his learning and life experience at his alma mater, telling the story of the teachers who carefully cultivated and patiently guided him, giving him wings to soar and achieve his dreams. Professor Zhen Fang presented pictures of student era materials to his younger students through carefully crafted courseware. The yellowed paper recorded the difficulties of learning during that special period and also documented the changes in education.

方真老师演讲Prof. Zhen Fang‘s speech

Meanwhile, he provided a detailed introduction to the learning methods and techniques of various subjects, the experience of preparing for the college entrance examination, methods of adjusting mentality, and how to efficiently use time and develop detailed and reasonable study plans based on his own experience that inspired students to bravely face challenges and persistently pursue their dreams.

方真老师回答学生问题Prof. Zhen Fang answers questions

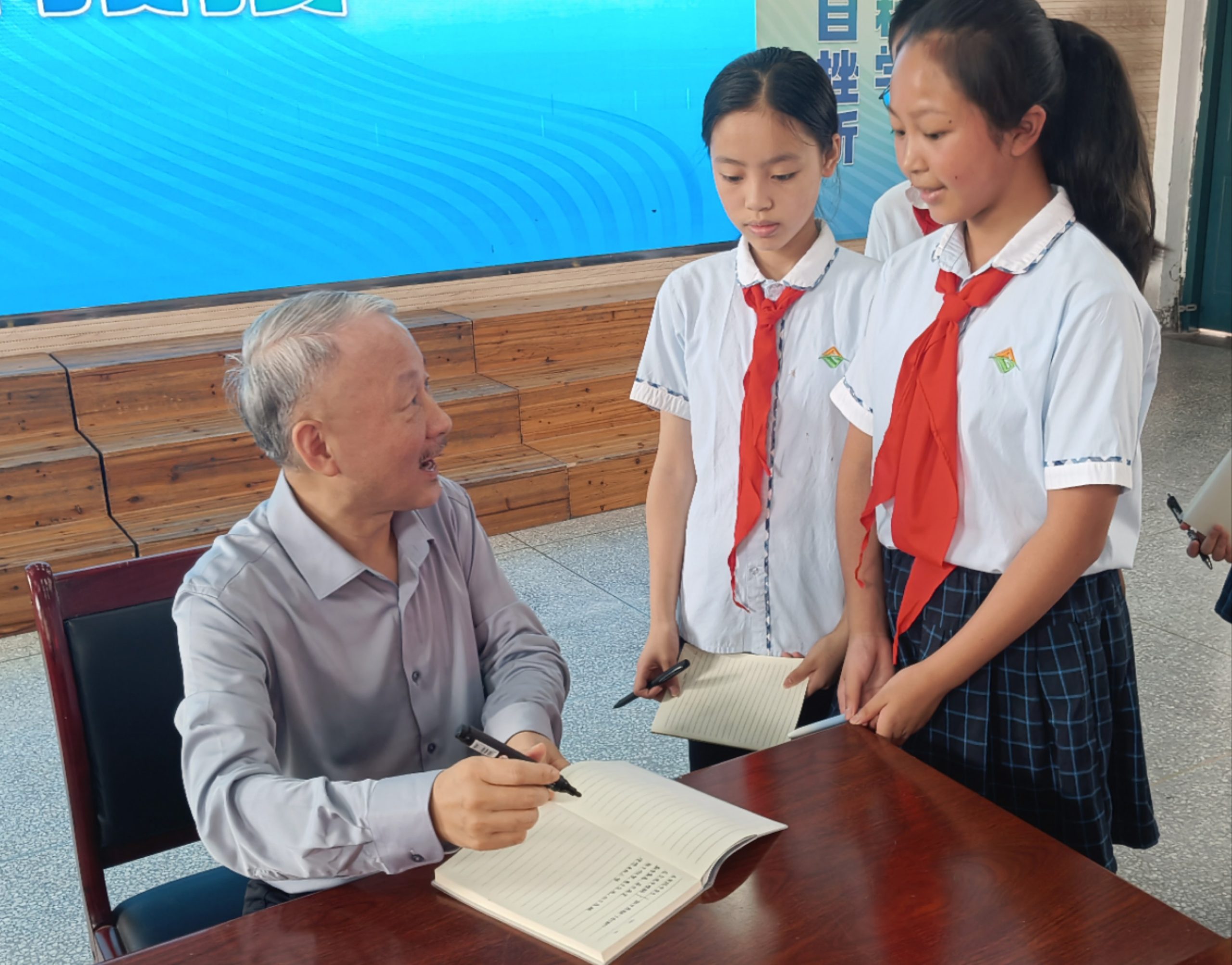

After lecture, students raised many interesting questions. Professor Zhen Fang patiently explained and responded with humor. They communicated and collided with each other, making the bond of campus inheritance even tighter. Prof. Zhen Fang hoped that the students would have dreams from an early age (see photos below):

“Ambition from Little,

Confidence from Success,

Thinking in Science,

Progress from Setback.”

方真老师鼓励学生Prof. Zhen Fang encourages students

Later, Mr. Xu director of the bureau of education of Taining and Mr. Xiao Principal of Taining No.1 Middle School, invited Prof. Zhen Fang to his Alma Mater to discuss the 100th anniversary celebration of the school next year. Prof. Zhen Fang and his delegation also visited a wooden board company in Taining to seek collabration, and gave presentations to the companies in Taining.

方真老师参访泰宁一民营板材厂Professor Zhen Fang visits a wooden board company in Taining

方真老师研究组与泰宁民营企业交流Professor Zhen Fang exchanges with private enterprises in Taining

我的成长心路历程 – 泰宁我梦想开始的地方

应谢世莲校长的邀请,2025年6月18日上午,南京农业大学方真教授(加拿大工程院院士)为纪念毕业50周年(1975-2025),在母校泰宁实验小学为学生们做了题为“我的学习经历——泰宁,我的梦想开始的地方”的讲座。泰宁实验小学创办于1905年,1953年正式命名为“实验小学”,1979年被确定为福建省重点小学。现有学生1800余人,教职工77人。

方真老师演讲Prof. Zhen Fang‘s speech

演讲中,方真教授深情回忆了自己在母校的学习生活经历,讲述了母校老师们精心培养和耐心指导,为自己圆梦插上腾飞的翅膀。方教授通过精心制作的课件向学弟学妹们展示了记录学生时代资料的图片,泛黄的纸张记录了在那个特殊的时期求学的不易,也记录了教育的变迁。

方真老师鼓励学生Prof. Zhen Fang encourages students

同时,他结合自己的经历详细介绍了各科学习方法和技巧、高考备考经验、调整心态的方法以及如何高效利用时间、如何制定详细且合理的学习计划等,他们鼓励同学们要勇敢面对挑战,坚持不懈地追求自己的梦想。

讲座结束后,同学们向方真老师提出了很多有趣的问题,方真老师耐心讲解,幽默回应,他们相互交流、碰撞,让校园传承的纽带愈发紧实。方真老师鼓励同学们长大后积极投身农业邻域,报考农业院校如南农和中农从事科研与农业创新,并希望同学们从小要有梦想 (见下图):

“理想来自小梦,自信来自成功,思想来自科学,进步来自挫折。”

“Ambition from Little,

Confidence from Success,

Thinking in Science,

Progress from Setback.”

方真老师个人愿望Prof. Fang’s personal wish

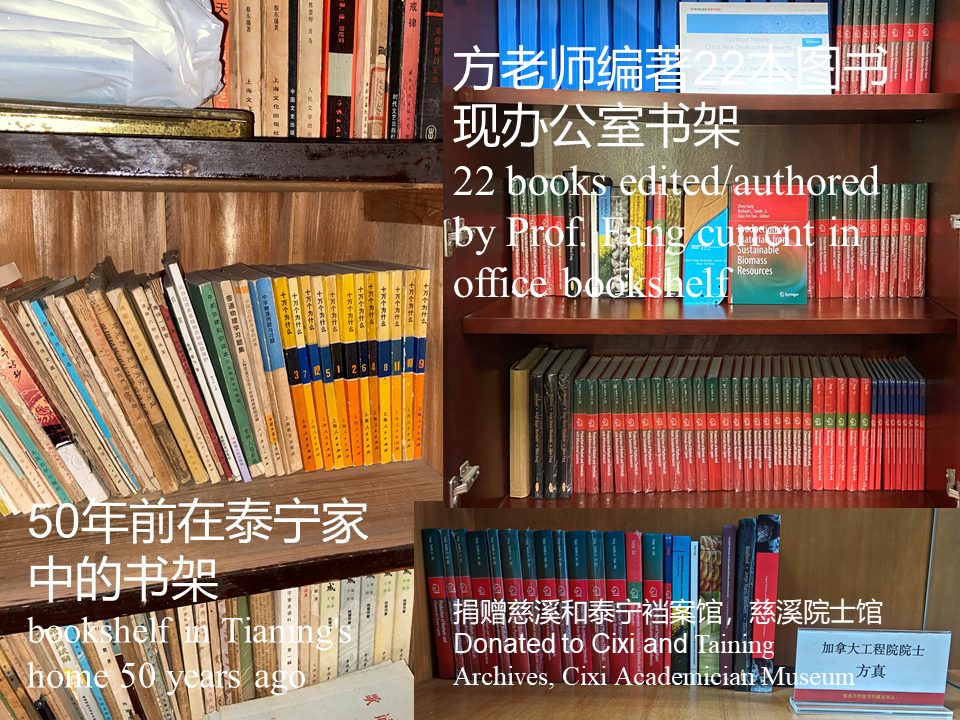

方真老师书架回答50年前梦想Prof. Fang’s bookshelf answers the dream in 50 years ago

之前方真教授一行还参观了泰宁的一家木板公司,寻求合作。随后,泰宁市教育局徐局长和泰宁一中肖校长邀请方真教授到母校讨论明年学校建校100周年庆典。2021年10月,方真老师曾经回泰宁一中母校演讲,鼓励同学们报考南京农业大学等一流大学。

https://cms.njau.edu.cn:8443/_vsl/3CE537F09CB0EEC4FC42F84CD8D4CB55/10E1AD95/3ABA5?noCache=me9pvzfx

https://cms.njau.edu.cn:8443/_vsl/13D17D86BF51F2CFDCD1E872AB01831B/43BA7134/3E2B4?noCache=me9pvzfx

https://cms.njau.edu.cn:8443/_vsl/70FC5417A7CC4EEFD6106DAF2E704433/1ADF28DD/30B8A?noCache=me9pvzfx