Biodiesel production direct from high acid value oil with a novel magnetic carbonaceous acid

Sulfonated activated carbon acid (AC-SO3H) can catalyze both esterification and transesterification to produce biodiesel from oils with high acid value (AV) without pretreatment. Because, activated carbon has properties like its surface oxides, reducibility, and stability in both acidic and basic media, as well as its structural resemblance to graphite , fullerenes and nanotubes to support -SO3H group well. However, the separation of AC-SO3H catalyst needs filtration or centrifugation that is energy and time consuming. So, many magnetic carbonaceous acids were successfully prepared that are easily separated by a magnet for cellulose hydrolysis, fructose dehydration and hydrolysis of polysaccharides. But these catalysts have low acid content (e.g., 1.3, 1.95 and 0.38 mmol/g) for effective biodiesel production, some have low magnetism.

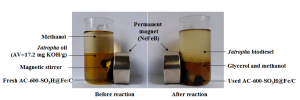

Mr. Zhang Fan, a PhD student, under the guidance of Professor Zhen Fang in Xishuangbanna Tropical Botanical Garden (CAS), prepared a cheap and active magnetic heterogeneous acid for the production of biodiesel from oils with high AV. First, magnetic core is formed by hydrothermal precipitation from both glucose and iron chloride and subsequent high temperature pyrolysis. The core is again hydrothermally coated with glucose and stabilized by pyrolysis, and subsequent sulfonated as acid catalyst. It was found that pyrolysis temperature at 600 °C led to excellent structure to produce catalyst with high acid density (2.79 mmol/g) and strong magnetism (14.4 Am2/kg). The catalyst presents high active, stable and recoverable in the production of Jatropha biodiesel from crude oil with high AV (17.2 mg KOH/g) with high yields for 3 cycles (90.5%, 91.8%, 90.3%), slight reduction in total acid density (2.43 vs. 2.79 mmol/g) and high catalyst recovery rate of 96.3%. It was also found that ultrasound can resist free fatty acids. High biodiesel yield (90.7%) was still achieved from high AV oil (4.8) at low US energy density (0.1 W/mL) with Na2SiO3 catalyst.

The results are published in Applied Energy and Fuel:

1. Fan Zhang, Z. Fang*, Y.T. Wang. Biodiesel production direct from high acid value oil with a novel magnetic carbonaceous acid, Applied Energy, 2015; 155: 637-647.

2. Fan Zhang, Z. Fang*, Y.T. Wang. Biodiesel production directly from oils with high acid value by magnetic Na2SiO3@Fe3O4/C catalyst and ultrasound, Fuel, 2015; 150: 370–377.

新型碳基磁性固体酸催化剂用于高酸值油脂直接转化合成生物柴油

直接用高酸值油脂制备生物柴油是一难点和研究热点。

磺化的活性炭可用于酯化和酯交换反应催化高酸值油脂制备生物柴油。因为活性炭具有类似于表面氧化物,还原剂和稳定的酸碱基团等特性,并且它的结构与石墨,富勒烯和碳纳米管相似并可以构建-SO3H酸基团。目前,已成功地研制出磁性碳基固体酸并用于磁场回收,例如分别用于纤维素水解、果糖降解和多糖水解的催化剂,但是以上催化剂较低的酸量(如:1.3, 1.95 and 0.38 mmol/g)或较弱的磁性不适用于生物柴油制备。

中国科学院西双版纳热带植物园生物能源组,博士生张帆在方真研究员的指导下,制备出一种廉价和高活性的磁性固体酸催化剂用于高酸值油脂制备生物柴油。催化剂的制备方法:首先通过葡萄糖和氯化铁混合溶液在高温水热条件下制备碳基磁核,然后利用水热碳化葡萄糖再次包埋热处理后的碳基磁核,最后通过高温热处理后进行磺化制备碳基磁性固体酸。研究发现在600 °C温度下热处理再磺化制备的固体酸,同时具有高酸量(2.79 mmol/g)和磁饱和度(14.4 Am2/kg),该催化剂具有高活性,稳定性和可回收性,循环3次用于小桐子生物柴油(生物柴油产率:90.5%,91.8%,90.3%; 小桐子油酸值17.2 mg KOH/g)制备,催化剂酸量略有下降(2.43 vs. 2.79 mmol/g)并且具有96.3%的回收率。同时,还发现,超声波能抗自由脂肪酸:以Na2SiO3为催化剂,在较低的超声波能量密度下(0.1 W/mL),高酸值小桐子油(4.8 mg KOH/g)的生物柴油产率仍然可以达到90.7%。

相关研究成果发表在国际著名能源期刊Applied Energy和Fuel上:

1. Fan Zhang, Z. Fang*, Y.T. Wang. Biodiesel production direct from high acid value oil with a novel magnetic carbonaceous acid, Applied Energy, 2015; 155: 637-647.

2. Fan Zhang, Z. Fang*, Y.T. Wang. Biodiesel production directly from oils with high acid value by magnetic Na2SiO3@Fe3O4/C catalyst and ultrasound, Fuel, 2015; 150: 370–377.