冷冻预处理秸秆Thermodynamic modeling of freeze pretreatment in the destruction of rice straw structure combined with alkaline-hydrothermal method for enzymatic hydrolysis

Thermodynamic modeling of freeze pretreatment in the destruction of rice straw structure combined with alkaline-hydrothermal method for enzymatic hydrolysis

Recently, PhD student Miss Qian Dong supervised by Prof. Zhen Fang published a research article in Bioresource Technology about freeze-pretreatment modeling and its combination with alkaline-hydrothermal method to enhance enzymatic hydrolysis of rice straw.

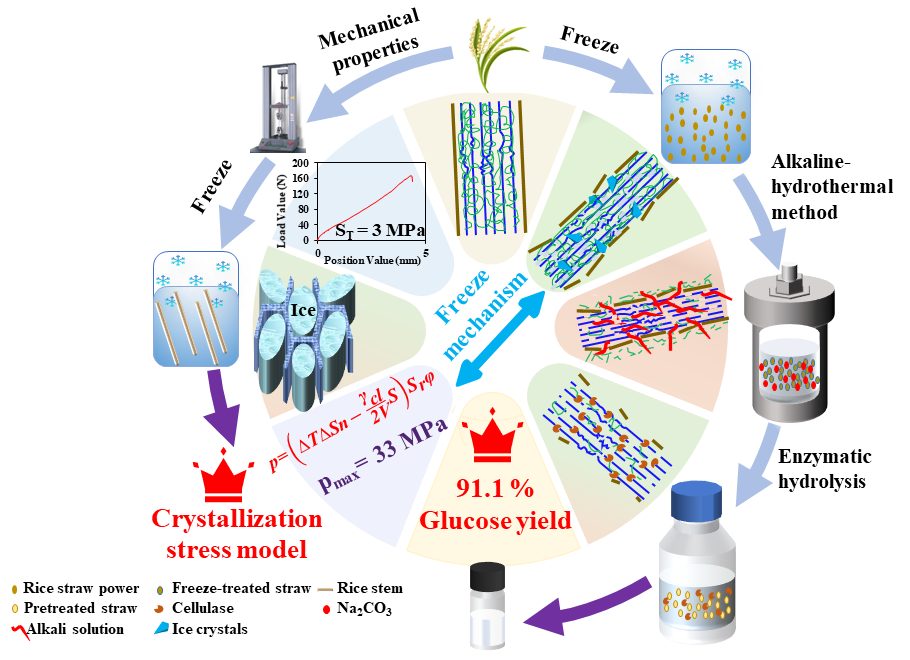

Freeze pretreatment combined with alkaline-hydrothermal method of rice straw for enzymatic hydrolysis was studied. Crystallization stress in the rice stem pores caused by water freezing at -20– -40 °C was modeled to illustrate the destruction mechanism. The stress was calculated as 22.5–38.3 MPa that were higher than the tensile yield stress of untreated stems (3.0 MPa), indicating ice formation damaging pore structure. After freeze at -20 °C, rice straw was further hydrothermally treated at 190 °C with 0.4 M Na2CO3, achieving 72.0 % lignin removal and 97.2 % cellulose recovery. Glucose yield rose to 91.1 % by 4.3 times after 24 h hydrolysis at 10 FPU loading of Cellic®CTec2 cellulase. The specific surface area of rice straw was 2.6 m2/g increased by 1.2 times after freeze. Freeze combined with alkaline-hydrothermal treatment is a green and energy-efficient method for improving enzymatic hydrolysis.

Related results were published in Bioresource Technology:

Q Dong, CX Gong, GL Xie, GQ Zhu, Zhen Fang*. Thermodynamic modeling of freeze pretreatment in the destruction of rice straw structure combined with alkaline-hydrothermal method for enzymatic hydrolysis. Bioresource Technology (IF 11.9), 403 (2024), 130864. https://doi.org/10.1016/j.biortech.2024.130864.

Crystallization stress in the rice stem pores was 33 MPa after freeze 4 times at -20 °C. Rice straw was pretreated by freeze-Na2CO3-hydrothermal treatment with 91.1% glucose yield after 24 h enzymatic hydrolysis. (在-20 °C条件下冷冻4次后,水稻茎秆孔内水产生的结晶应力为33 MPa。采用冷冻辅助Na2CO3水热预处理稻秆,酶解24 h后葡萄糖产率为91.1%。)

冷冻预处理热力学建模及其结合碱性水热法破坏稻秆结构用于酶解

近期,博士生董倩同学在方真教授的指导下,在国际学术期刊Bioresource Technology (Q1,IF 11.4)发表一篇关于冷冻预处理热力学建模及其结合碱性水热法处理水稻秸秆用于酶解的研究性论文。

采用冷冻联合碱水热预处理水稻秸秆。通过建立水稻茎秆中水冻结(-20– – 40 °C)引起的结晶应力模型来阐明冷冻预处理的破坏机制。冷冻产生的结晶应力为22.5–38.3 MPa,高于未处理茎秆的拉伸屈服应力(3.0 MPa),表明冷冻预处理破坏了水稻茎秆的孔隙结构。水稻秸秆在-20 °C冷冻后进行碱水热处理(190 °C, 0.4 M Na2CO3),木质素去除率为72.0%,纤维素回收率为97.2%。在10 FPU Cellic®CTec2纤维素酶负载下水解24 h后,葡萄糖的产率提高了4.3倍,达到91.1%。冷冻预处理后,水稻秸秆比表面积为2.6 m2/g,提高了1.2倍。冷冻联合碱性水热处理是一种绿色节能的改善酶解的方法。

结果发表在Bioresource Technology:

Q Dong, CX Gong, GL Xie, GQ Zhu, Zhen Fang*. Thermodynamic modeling of freeze pretreatment in the destruction of rice straw structure combined with alkaline-hydrothermal method for enzymatic hydrolysis. Bioresource Technology (IF 11.9), 403 (2024), 130864. https://doi.org/10.1016/j.biortech.2024.130864.