星期四, 30 9 月, 2021

航空燃料合成Lanthanide catalyst for synthesis of jet fuel intermediates

Recently, master student Miss Lu-ping Li supervised by Dr. Xiao Kong and Prof. Zhen Fang published a research article in Molecular Catalysis about the synthesis of jet fuel intermediates.

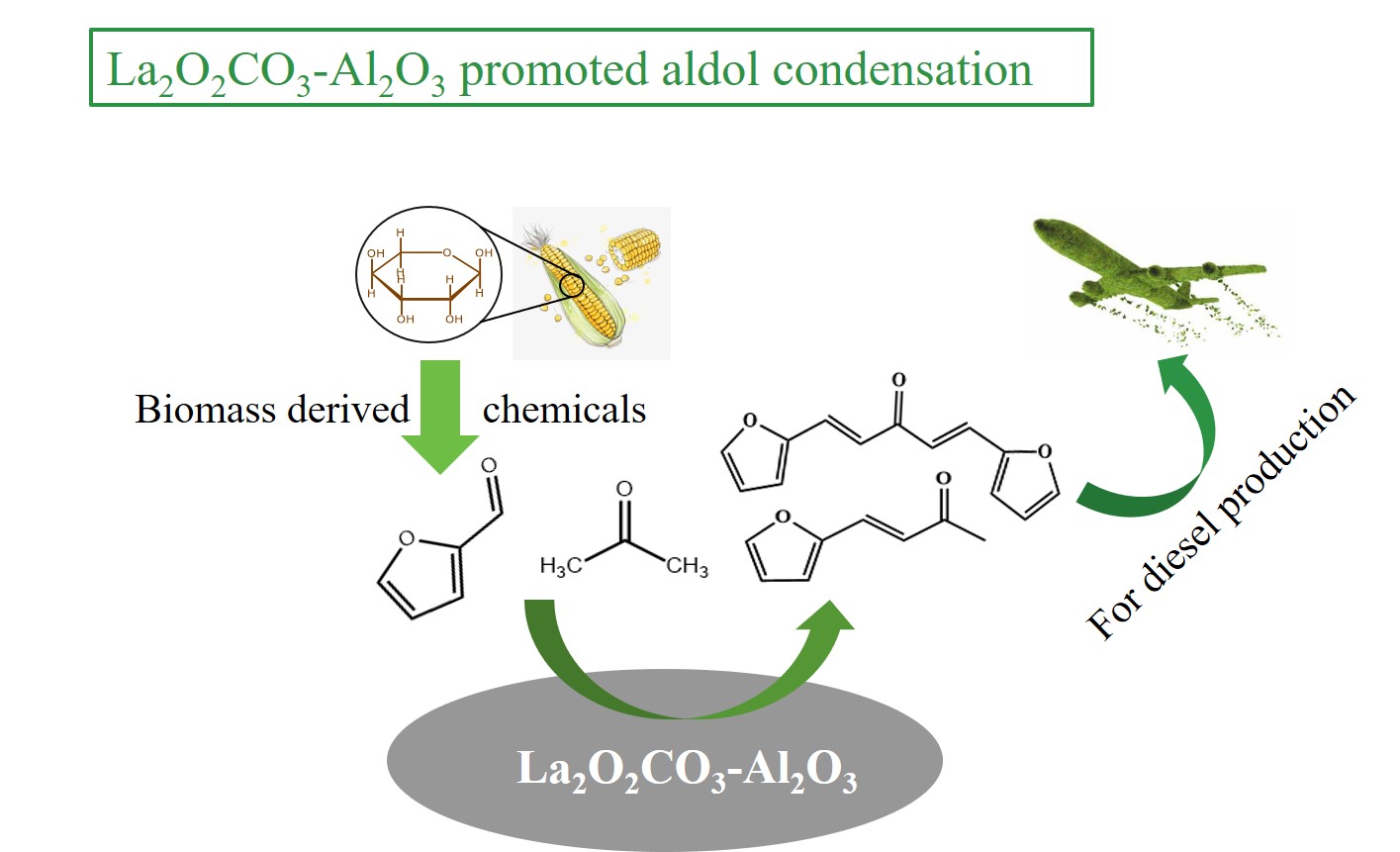

Jet fuel precursors (4-(2-furyl)-3-buten-2-one (FAc) and 1,5-di-2-furanyl-1,4-pentadien-3-one (F2Ac)) can be produced from aldol condensation between furfural and acetone over basic catalysts. However, there is still a need to develop efficient alkaline catalysts and understand the role of alkaline sites. In this work, La2O2CO3-Al2O3 catalyst was successfully prepared by coprecipitation and the effect of preparation conditions on the properties and catalytic performance was investigated. Experiments showed that La2O2CO3 and La2O3 were formed after calcination, and the activity was greatly improved by the introduction of La2O2CO3. At higher coprecipitation pH, rod-shaped La2O2CO3 was formed, exposing basic La3+-O2- sites for good performance in aldol condensation reactions. The catalytic performance of La2O2CO3-Al2O3 in aldol condensation of furfural with acetone was also evaluated and compared with that of Al2O3, La2O3, La2O3-Al2O3, La(OH)₃/Al2O3 and La2O2CO3/Al2O3. A total conversion of furfural can be realized with F2Ac yield of 67.8% at a furfural/acetone ratio of 1/1 and 90 oC, with a FAc yield of 25.8% at the same time. The deactivation mechanism of the La2O2CO3-Al2O3 catalyst was also studied.

Liquid fuel precursors can be produced by furfural-acetone aldol condensation over La2O2CO3-Al2O3 catalyst with C13 yield of 67.8%(通过糠醛和丙酮之间的羟醛缩合在La2O2CO3-Al2O3催化剂上制备液体燃料中间体,C13产率为67.8%)

Related results were published in Molecular Catalysis:

Lu-ping Li, Zhen Fang*, Xiao Kong*, Wen-Jie Cong, Molecular Catalysis, 515, 111893 (2021). https://doi.org/10.1016/j.mcat.2021.111893.

—————————————–

镧系催化剂合成航空燃料中间体

最近,硕士生李路平(女)在方真老师和孔晓博士的指导下,在国际学术期刊Molecular Catalysis(IF5.062,Q2)上发表关于镧系催化剂用于合成航空燃料中间体的研究文章。

通过糠醛和丙酮的羟醛缩合可以在碱性催化剂上获得航空燃料前体呋喃加合物4-(2-呋喃基)-3-丁烯-2-酮(FAc)和1,5-二-2-呋喃基-1,4-戊二烯-3-酮(F2Ac)。然而,仍然需要开发有效的碱性催化剂并了解碱性位点的作用。本工作采用共沉淀法成功制备了La2O2CO3-Al2O3催化剂,并研究了制备条件对其结构和催化性能的影响。实验表明,经煅烧后形成La2O2CO3和La2O3,而La2O2CO3极大的提高了催化活性。在较高的共沉淀pH值下可以形成棒状的La2O2CO3,并暴露出更多的La3+-O2-碱性位点,在羟醛缩合反应中表现出良好的性能。之后,在糠醛与丙酮的羟醛缩合实验中评价了La2O2CO3-Al2O3的催化性能,并与Al2O3、La2O3、La2O3-Al2O3、La(OH)3/Al2O3和La2O2CO3/Al2O3的进行了催化性能的比较。在糠醛/丙酮比为1/1和90 oC下,糠醛的总转化率为67.8%,同时FAc产率为25.8%。最后研究了La2O2CO3-Al2O3催化剂的失活机理。详情可见:

Lu-ping Li, Zhen Fang*, Xiao Kong*, Wen-Jie Cong, Molecular Catalysis, 515, 111893 (2021). https://doi.org/10.1016/j.mcat.2021.111893.