溶解木质纤维素生物质以促进其水解 陈敬妹

星期四, 19 11 月, 2015近日,方真研究员应 “生物燃料,生物制品和生物炼制”(他担任该刊顾问编委) 邀请,为该刊关于生物能源技术发展撰写社论。方真研究员建议设计并找到一种新的廉价和绿色的溶剂,在温和的条件下,溶解木质纤维素生物质,在均相的条件下进行生物炼制。

全球每年生物质生产量相当于8倍的世界能源消耗。大部分生物质是以木质纤维素的形式存在,含有75%的单糖(例如,木材和草:50%的纤维素和25%半纤维素)。问题的关键是如何释放这些丰富的生物聚合物成为水溶性糖,它们可很容易随后再转化为乙醇,脂类,其他生物燃料,各种化学品,食品和药品。

通常,有三种典型的方法水解木质纤维素为可发酵糖:(ⅰ)预处理后,在低温下酶解(例如,50摄氏度);(ⅱ)在温和的温度下催化水解(例如,180摄氏度),和(iii)在高温近临界点下,快速水解(如350摄氏度)。溶解生物质以形成均相“生物质溶液”对于水解和预处理是非常重要的。溶解后的“生物质溶液”可像液态石油(而不是固体煤)一样,很容易加工,并可实际用于流动反应装置来提高生产效率。有机溶剂(例如,γ戊内酯,γ-valerolactone),离子液体和超临界流体均可以溶解生物质来水解。

生物质溶解后,这三种水解方法可以进一步改进以提高实际用途:(ⅰ)酶水解:酶,水和生物质分子可在一个均相条件下完全水解,不需要预处理步骤。然而,应考虑在工业生产中,如何回收酶,保持其较高的活性和降低成本。 (ii)催化水解:水解过程可用于流动反应装置以提高生产效率。与此同时,固体催化剂可替代液体酸,这样更绿色和环保。然而,固体催化剂的稳定性和活性需要进一步研究。 (iii)快速水解技术:尽管其效率高,但是,由于水解条件苛刻(如高温高压),工程问题(如反应器设计,材料和连续操作)等将成为障碍其商业化的关键。

1、Zhen Fang*, How Can We Best Solubilize Lignocellulosic Biomass for Hydrolysis? Biofuels Bioproducts and Biorefining, 9, 621–622 (2015) (invited editorial).

Solubilization of Lignocellulosic Biomass for Hydrolysis

By Jing-Mei Chen

Recently, Prof. Zhen Fang was invited to write an Editorial in “Biofuels, Bioproducts and Biorefining” (He is also serving as advisory editorial board member for this Journal). He suggested to design and find a green and inexpensive solvent to solubilize lignocellulosic biomass at mild conditions for novel biorefineries.

Annual global biomass production is equivalent to 8 times the world’s energy consumption. Most of biomass is in lignocellulosic form that contains 75% sugar units (e.g., wood and grass plants: 50% cellulose and 25% hemi-cellulose). The key is how to release these abundant biopolymers to become water-soluble sugars that are easily subsequently converted into ethanol, lipids, other bio-fuels, various chemicals, foods, and medicines. There are three typical methods to hydrolyze lignocelluloses to sugars.

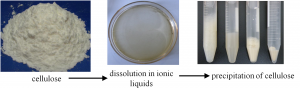

Typically, the three ways are used for hydrolysis: (i) enzymatic hydrolysis after pretreatment at low temperatures (e.g., 50 oC), (ii) catalytic hydrolysis at mild temperatures (e.g., 180 oC), and (iii) fast hydrolysis at high temperatures near critical point (e.g., 350 oC). It is very important to solubilize biomass to form a homogenous phase for hydrolysis and pretreatment. The homogenous biomass solution (like petroleum not solid coal) is also easily processed in a flow system for practical applications. Organic solvents (e.g., γ-valerolactone), ionic liquids and supercritical fluids can dissolve actual biomass for hydrolysis.

After biomass solubilization, the three hydrolysis methods can be further improved for practical uses: (i) for enzymatic hydrolysis; enzymes, water and biomass molecules mix well in a homogenous phase for complete hydrolysis, pretreatment step is not required. However, how to recycle enzymes, keep high activity and reduce their cost should be considered for industrial production. (ii) For catalytic hydrolysis; a flow process can be built up to increase production efficiency. At the same time, solid catalysts may replace liquid acids for a green process. However, their stability and activity need study further. (iii) For fast hydrolysis; even though its high efficiency, however, owing to severe conditions (high temperature and pressure), engineering issues (such as reactor design, materials and continuous operation) become key obstacle to commercialize it.

1、Zhen Fang*, How Can We Best Solubilize Lignocellulosic Biomass for Hydrolysis? Biofuels Bioproducts and Biorefining, 9, 621–622 (2015) (invited editorial).

Cellulose completely dissolves in an ionic liquid for hydrolysis or pretreatment

纤维素完全溶解在离子液体中进行水解或预处理