富芳烃燃料 Synthesis of aromatic-rich biofuels by catalyzed co-pyrolysis of lignin and waste polyoxymethylene (POM).

Sustainable production of aromatic-rich biofuel via catalytic co-pyrolysis of lignin and waste polyoxymethylene over commercial Al2O3 catalyst

Recently, under the guidance of Associate Professor Lu-jiang Xu, master student Mr. Ge-liang Xie published an article on the preparation of high aromatic biofuels by lignin and waste polyoxymethylene (POM) catalytic co-pyrolysis in the journal Journal of Analytical and Applied Pyrolysis.

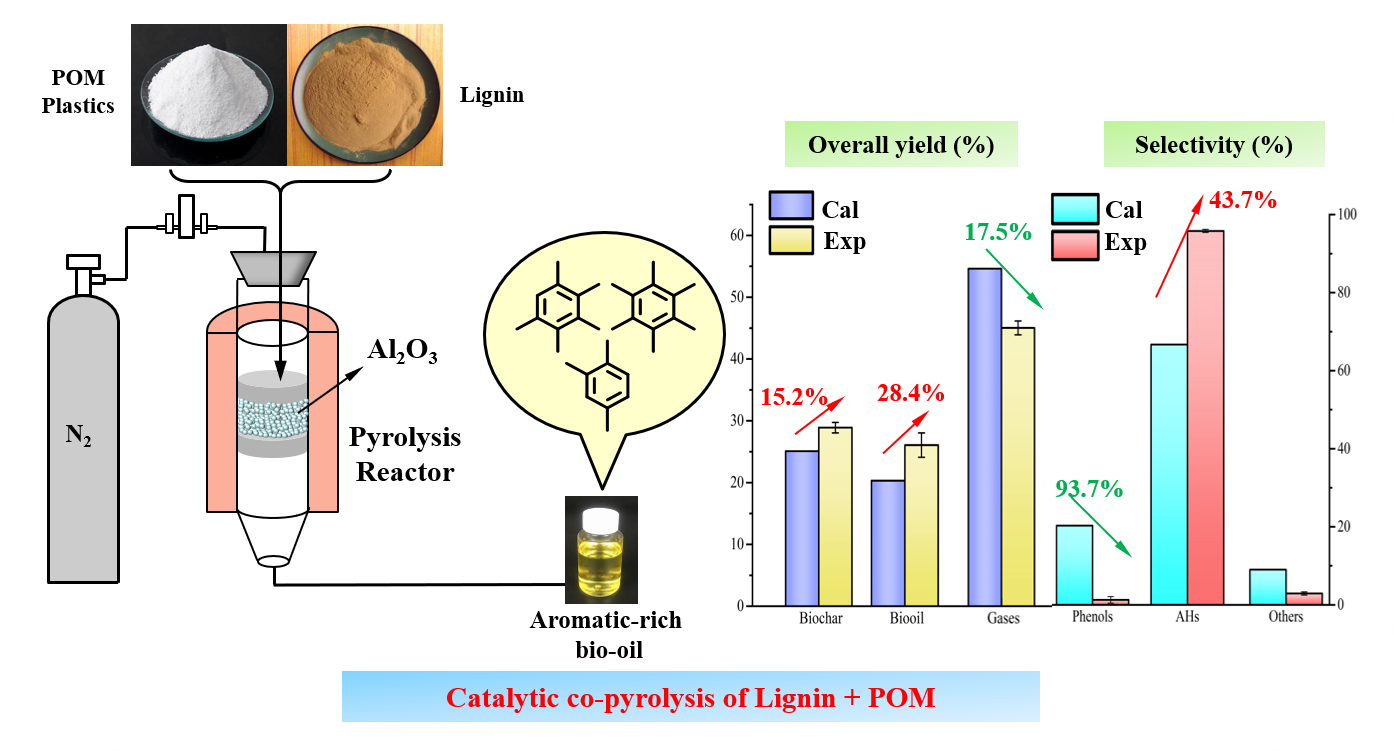

Co-valorization of biomass and multiple solid wastes is essential to environment protection and energy security. Herein, aromatic-rich biofuel was produced from lignin and waste polyoxymethylene (POM) via catalytic co-pyrolysis process. Commercial and cheap γ-Al2O3 catalyst exhibited good catalytic performance. Series characterizations and bench-top pyrolysis experiments were conducted to illustrate the synergism between raw materials and the mechanism of aromatics formation. The TG analysis and thermodynamics calculation revealed that a remarkably positive synergistic effect existed between lignin and POM, could reduce the activation energies, and make the reaction more conducive in terms of thermodynamics. Meanwhile, the yields of biochar and bio-oil increased considerably Additionally, the operating conditions affected the product distributions significantly. The suitable mixing ratio of lignin to POM was around equal (5:5) with the bio-oil yield increased by 25% to 28.3% and aromatic hydrocarbons selectivity increased to >95%. Moreover, POM, the precursor for alkylating reagents and hydrogen donors, could promote the deoxygenation reactions of phenolic intermediates and result into aromatic hydrocarbons. The acid sites of γ-Al2O3 promoted series secondary cracking reactions (alkylation, deoxygenation), and thus improve bio-oil quality. Finally, the stability test showed that commercial γ-Al2O3 catalyst was slightly deactivated after 4 cycles because of coke deposits and acid sites loss.

Related results were published in Journal of Analysis and Applied Pyrolysis:

GL Xie, GQ Zhu, T Lv, YF Kang, YH Chen, Z Fang, LJ Xu*, Sustainable production of aromatic-rich biofuel via catalytic co-pyrolysis of lignin and waste polyoxymethylene over commercial Al2O3 catalyst, Journal of Analytical and Applied Pyrolysis, 174, 106147, https://authors.elsevier.com/c/1hiQybaW~3r4b (2023).

Using lignin and waste acetal (POM) as raw materials and commercial γ-Al2O3 as catalyst, aromatic-rich biofuels were prepared by catalytic co-pyrolysis process. The suitable mixing ratio of lignin and polyoxymethylene was about 5∶5, the yield of bio-oil increased by 25% to 28.3%, and the selectivity of aromatic hydrocarbons increased to >95%.以木质素和废聚甲醛(POM)为原料,商业γ-Al2O3作为催化剂,采用催化共热解工艺制备了富含芳烃的生物燃料。在木质素与聚甲醛的适宜混合比例下(5∶5),生物油收率提高了25%至28.3%,芳烃选择性提高至>95%。

通过商业Al2O3催化剂催化木质素和废聚甲醛的共热解可持续生产富含芳烃的生物燃料

近日,在徐禄江副教授的指导下,硕士生谢葛亮先生在《分析与应用热解杂志》(IF 6.0)上发表了一篇关于木质素与废聚甲醛催化共热解制备高芳烃生物燃料的研究性论文。

生物质和多种固体废物的联合定价对环境保护和能源安全至关重要。以木质素和废聚甲醛(POM)为原料,采用催化共热解工艺制备了富含芳烃的生物燃料。市售廉价的γ-Al2O3催化剂具有良好的催化性能。通过系列表征和台架热解实验,阐明了原料之间的协同作用和芳烃的形成机理。TG分析和热力学计算表明,木质素与聚甲醛之间存在显著的正协同作用,可以降低活化能,使反应在热力学上更有利于进行。同时,生物炭和生物油的产率显著提高,操作条件对产物分布有显著影响。木质素与聚甲醛的适宜混合比例约为5∶5,生物油收率提高了25%至28.3%,芳烃选择性提高至>95%。此外,POM作为烷基化试剂和氢供体的前体,可以促进酚类中间体的脱氧反应,生成芳烃。γ-Al2O3的酸性位点促进了一系列的二次裂化反应(烷基化、脱氧),从而提高了生物油的质量。最后,稳定性测试表明,商业γ-Al2O3催化剂在4次循环后由于焦炭沉积和酸位损失而轻微失活。

结果发表在Journal of Analysis and Applied Pyrolysis:

GL Xie, GQ Zhu, T Lv, YF Kang, YH Chen, Z Fang, LJ Xu*, Sustainable production of aromatic-rich biofuel via catalytic co-pyrolysis of lignin and waste polyoxymethylene over commercial Al2O3 catalyst, Journal of Analytical and Applied Pyrolysis, 174, 106147, https://authors.elsevier.com/c/1hiQybaW~3r4b (2023).