中农校庆报告“Renewables Solutions forOur Global Challenges” Keynote Talk at CAU 120th Anniversary

28 11 月, 2025“Renewables Solutions for Our Global Challenges” Keynote Talk at CAU 120th Anniversary

北农机(中农)-我梦想开始的地方Beijing Agricultural Mechanization Institute (CAU) – Where My Dream Started

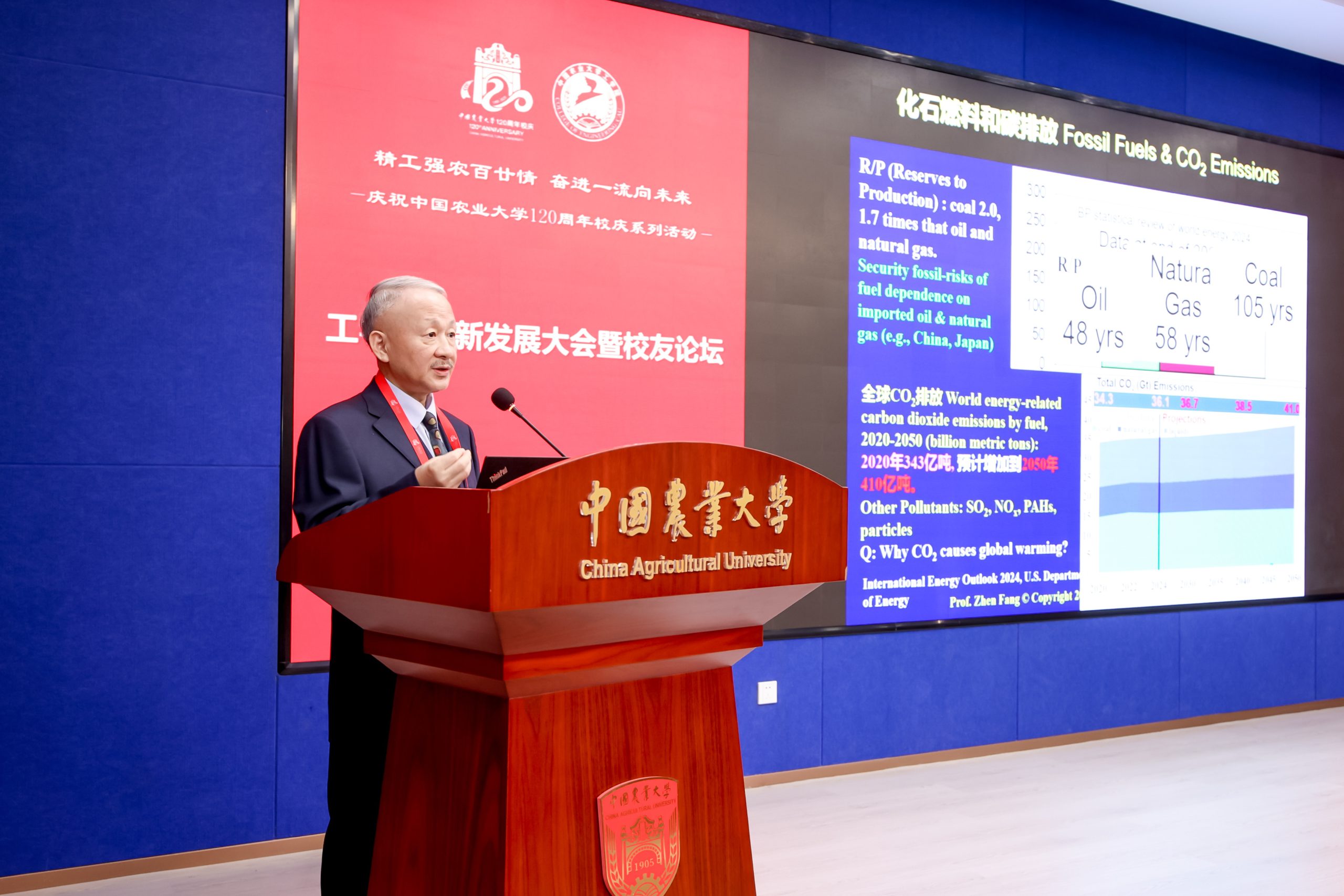

At the invitation of Mr. Yong Yu, Party Committee Secretary of the College of Engineering at China Agricultural University (CAU), and Dean Mr. Zhenghe Song, Prof. Zhen Fang attended the Innovation Development Conf. and Alumni Forum of the College of Engineering, celebrating the 120th anniversary of CAU and the 73rd anniversary of the College of Engineering. On the afternoon of October 14, 2025, at 13:10, with a clear sky and no clouds in sight, Prof. Zhen Fang and his delegation of three set off from Nanjing, boarding the high-speed train to Beijing. They arrived at Beijing South Station at 16:38 pm the same day. An hour later, they reached CAU Jinmao Building and met with Dean Mr. Song of the College of Engineering. The next morning, Prof. Zhen Fang participated in the Conf. held in the auditorium of the new library at the East Campus and delivered a keynote speech. Mr. Jiguang Shan, Deputy Party Committee Secretary, Discipline Inspection Commission Secretary, and National Supervisory Commission Resident Commissioner of CAU, attended the conference on behalf of the university.

Prof. Zhen Fang’s talk entitled:

“Renewable Energy Solutions to Global Challenges”

1.Global Challenges & Renewables Role

2.BioResources and Biorefining Solutions

3.Hydrolysis into monosaccharides

(1) Fast hydrolysis

(2) Catalytic hydrolysis

(3) Enzymatic hydrolysis

4.Chemical and biological conversion of sugar into high-added-value products

5.Biodiesel

6.Conclusion and Applications

7.My Wishes

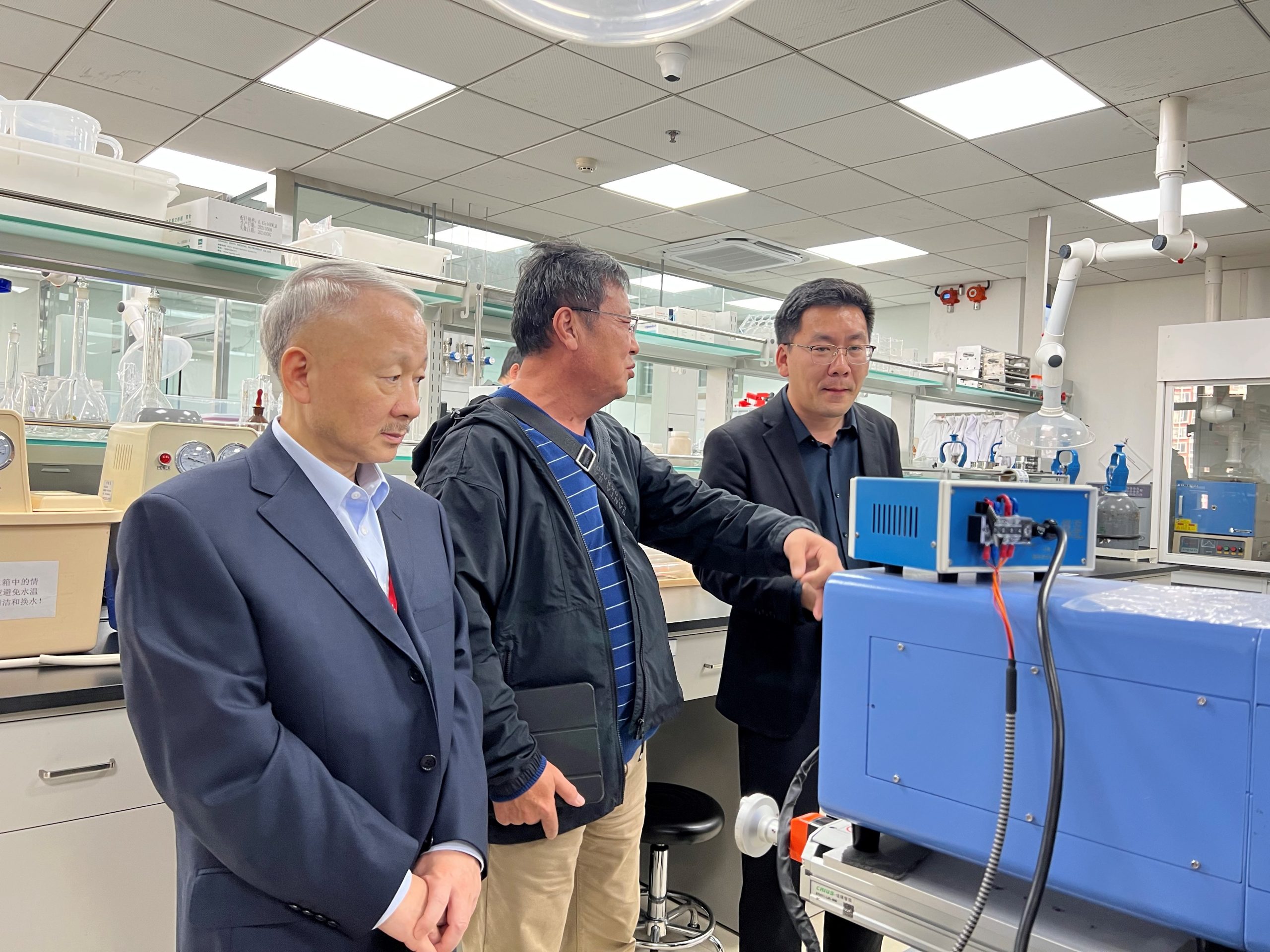

After lunch, Profs. Zhen Fang and Weiming Yi went to the lobby on the first floor of the College of Engineering to pay respects to their supervisor, Academician Dechao Zeng, the Founder of Agricultural Machinery and Agricultural Engineering in China. They then visited Prof. Lujia Han’s laboratory and had discussions with young teachers. At 3:30 pm in the afternoon, at the invitation of Prof. Zhidan Liu, they went to the College of Water Resources and Civil Engineering to exchange and discuss with all the members in the research group.

The next morning, Prof. Zhen Fang attended the 120th Anniversary High Quality Development Conf. of CAU at the Olympic venue in the East Campus. Before the meeting, Prof. Zhen Fang specially walked into the first row to greet Prof. Yinqian Ai, the first-term Party Secretary of new CAU after the merger of Beijing Agricultural Mechanization Institute and Beijing Agricultural University in 1995. After lunch, Prof. Zhen Fang hummed the song “Returning from Target Shooting” learnt in his fourth grade of primary school, conducted by the female squad leader from the 6789 unit (anti-aircraft artillery 72ed division garrison) courtyard in Taining. Dragging his tired body, he stepped onto the window of the southbound Nanjing high-speed railway train, ending a hard and exciting visit.

中国农业大学120周年校庆主旨报告“全球挑战的可再生能源解决方案“

应中国农大工学院尤泳书记和宋正河院长邀请,方真教授参加工学院创新发展大会暨校友论坛,庆祝中国农业大学120周年华诞暨工学院建院73周年。2025年10月14日下午13:10 pm,天空晴朗,万里无云,方真教授一行三人怀着无比喜悦的心晴从南京出发,坐在北上北京高铁的窗口,下午16:38 pm抵达北京南站。一小时后抵达中农金码大厦,会见工学院宋正河院长。第二天一早,方真教授参加了在东校区新图书馆报告厅大会并作主旨报告,学校党委副书记、纪委书记、国家监委驻中国农业大学监察专员单际国代表学校出席大会。

方真教授报告题目:

“全球挑战的可再生能源解决方案”

1.地球挑战和可再生能源角色

2.生物资源和生物炼制方案

3.水解 为单糖

(1)快速水解

(2)催化水解

(3)酶解

4.化学和生物转化糖为高附加产物

5.生物柴油

6.结论和应用

7.我的愿望

午饭后,方真教授和易维明教授一行赴工学院一楼大厅祭拜导师中国农业机械和农业工程学科奠基人曾德超院士,随后参观韩鲁佳教授实验室并和青年教师交流座谈。下午3:30 pm, 应刘志丹教授邀请,赴水利与土木工程学院与研究组全体同志交流座谈。

第二天一早,在学校奥运馆参加中国农业大学建校120周年高质量发展大会。会前,特别走进第一排问候1995年北农机和北农合并为中国农大后,第一任党委书记艾荫谦老师(原北农机书记)。午饭后方老师唱着小学四年级泰宁6789部队大院子弟女班长指挥的《打靶归来》,踏上南下南京高铁列车的窗口,结束了辛苦和兴奋的访问。

主旨演讲 Keynote speech

主旨演讲Keynote speech

杰出校友Outstanding alumni

易维明副校长,尹飞虎院士,阮榕生院士合影(左至右)Vice-President Weiming Yi, Academician Feihu Yin, and Academician Rongsheng Ruan (left to right)

肖卫华教授,易维明副校长,尹飞虎院士,阮榕生院士,韩鲁佳教授和刘志丹教授合影(左至右)Prof. Weihua Xiao, Vice-President Weiming Yi, Academician Feihu Yin, Academician Rongsheng Ruan, Prof. Lujia Han, and Prof. Zhidan Liu taking a group photo (left to right)

韩鲁佳教授,易维明副校长,阮榕生院士亲切交谈(左至右)Prof. Lujia Han, Vice-President Weiming Yi, and Academician Rongsheng Ruan had a cordial conversation (left to right)

工学院大厅祭拜导师曾德超院士Worshipping supervisor Academician Dechao Zeng in the hall of the Engineering of Engineering

工学院大厅和前辈校友合影In the hall of the Engineering of Engineering

参观韩鲁佳和张雪松教授实验室Visiing Profs. Lujia Han and Xuesong Zhang’s laboratory

与刘志丹教授研究组座谈和交流Discussion and exchange with Prof. Zhidan Liu’s research group

参加校庆大会Attending CAU anniversary conference

亲切问候中农第一任党委书记艾荫谦老师(原北农机书记)Kind greetings to Prof. Yinqian Ai, the first-term Party Secretary of new merged CAU

校庆大会合影Group photo of CAU anniversary conference