生物燃料和生物炼制丛书:Springer 新书Springer book “Production of Organic Acids and Alcohols from Agricultural Residues and Food Wastes”

2 5 月, 2025

生物燃料和生物炼制丛书:https://link.springer.com/bookseries/11687

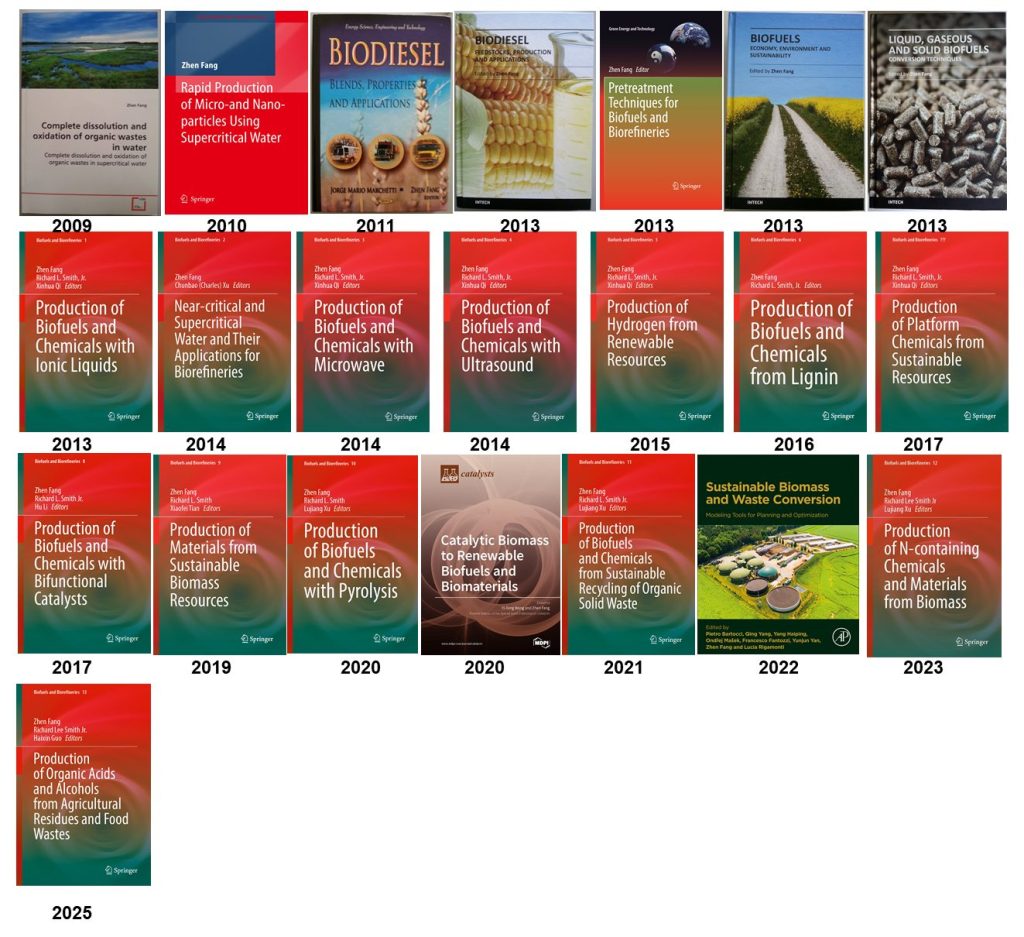

该书是斯普林格系列丛书“生物燃料和生物炼制– Biofuels and Biorefineries”(方真老师担任该丛书总编辑)出版的第十三本专著,也是方真老师自2009年以来,编著出版的第二十二部英语专著。

Springer book “Production of Organic Acids and Alcohols from Agricultural Residues and Food Wastes”

Recently, Springer has published a book entitled“Production of Organic Acids and Alcohols from Agricultural Residues and Food Wastes” edited by Profs. Zhen Fang, RL Smith Jr. and Dr. HX Guo, Springer, Hardcover ISBN 978-981-96-1221-5, 455 pages, 2025 (https://doi.org/10.1007/978-981-96-1222-2) .

Biomass-derived organic acids and alcohols focuses on recent technological developments and related challenges surrounding process for industrial applications. This book covers the recent development processes (e.g. catalytic conversion, hydrothermal conversion, fermentation and anaerobic digestion) available for agricultural residues or food wastes conversion into organic acid and alcohols. Highlighting the advantages and limitations of different technologies, presenting the challenges, innovative state-of-the-art technologies and assessing future perspectives on the process of biomass-derived organic acid or alcohol production. This book also provides diverse examples of application of biomass-derived organic acid and alcohol, such as production polymer and amino acid. Overall, the objective of this book is to provides the reader to understanding of the importance of biomass-derived organic acid and alcohols. The scope of text encompasses lignocellulosic biomass, agricultural residues, food wastes, biomass-derived compounds and fundamental carbohydrates with the aim to develop overall production strategies for organic acids and alcohols.

This book is the 13th book of the series entitled, “Biofuels and Biorefineries” (Prof. Zhen Fang is serving as Editor-in-Chief), and the 22nd English book edited/authored by Prof. Zhen Fang since 2009), and contains 12 chapters contributed by leading experts in the field. The text is arranged into two key parts:

Part I. Production of Organic Acids via Catalytic Processes of Agricultural Residues (Chapters 1-9)

Part II. Production of Biofuels from Agricultural Residues and Food Wastes (Chapters 10-12)

The text should be of interest to professionals in academia and industry who are working in the fields of natural renewable materials, platform chemicals, polymer, and materials. It can also be used as comprehensive references for university students with backgrounds in chemical engineering, material science, microbial chemistry and environmental engineering.

Biofuels and Biorefineries:

https://link.springer.com/bookseries/11687

斯普林格新书《农业废弃物和食物垃圾生产有机酸和醇》出版

由方真教授、日本东北大学RL Smith Jr.教授和中国农科院郭海心研究员主编的新书《农业废弃物和食物垃圾生产有机酸和醇》,最近由斯普林格公司出版发行。(精装,455页, ISBN 978-981-96-1221-5, 2025 (https://doi.org/10.1007/978-981-96-1222-2) .

本书生物质衍生的有机酸和醇生产侧重于最近的技术发展和围绕工业应用过程的相关挑战。它涵盖了农业废弃物和食品废物转化为有机酸和醇类的最新发展过程(如催化转化、水热转化、发酵和厌氧消化)。强调不同技术的优势和局限性,介绍挑战、创新的最新技术,并评估生物质衍生有机酸或酒精生产过程的未来前景。 本书还提供了生物质衍生有机酸和醇的各种应用实例,如生产聚合物和氨基酸。总的来说,本书的目的是让读者了解生物质衍生有机酸和醇类的重要性。文本范围包括木质纤维素生物质、农业残留物、食物垃圾、生物质衍生化合物和基本碳水化合物,旨在制定有机酸和醇类的整体生产策略。

这本书是题为“生物燃料和生物精炼厂”的系列中的第十三本书,包含该领域顶尖专家撰写的12章。本文分为两个关键部分:

第一部分:农业废弃物催化法生产有机酸(第1-9章)

第二部分:利用农业废弃物和食物残渣生产生物燃料(第10-12章)

该文本应该引起学术界和工业界在天然可再生材料、平台化学品、聚合物和材料领域工作的专业人士的兴趣。它也可以作为具有化学工程、材料科学、微生物化学和环境工程背景的大学生的综合参考。