Subcritical water gasification of lignocellulosic wastes for hydrogen production with CoNi/Al2O3

Recently, master student Mr. Jie Sun supervised by Prof. Zhen Fang collaborated with Profs. JA Kozinski at Waterloo and AK Dalai at U of Saskatchewan in Canada, published a research article in J Supercrit Fluids about hydrogen production from lignocellulosic wastes with CoNi/Al2O3 catalysts.

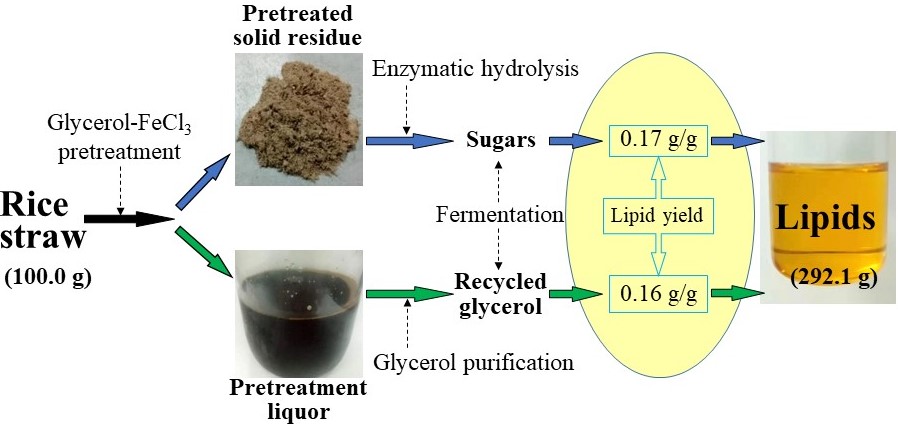

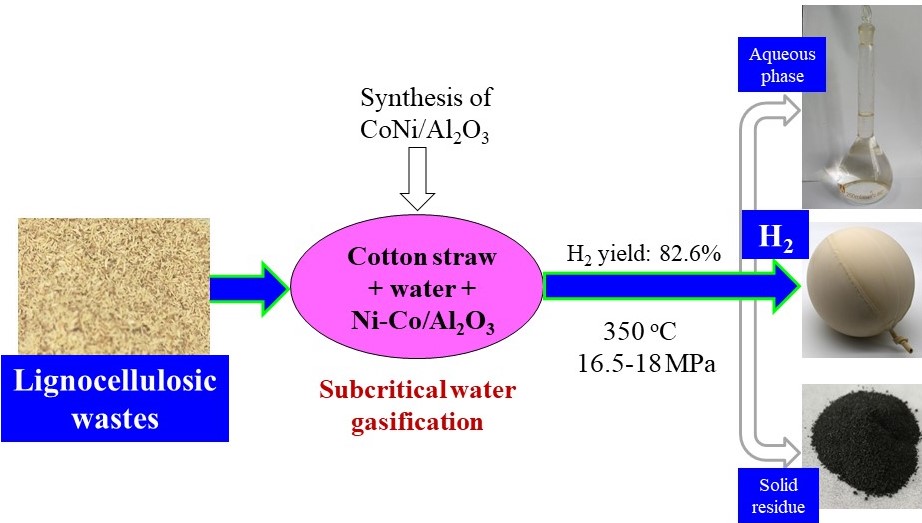

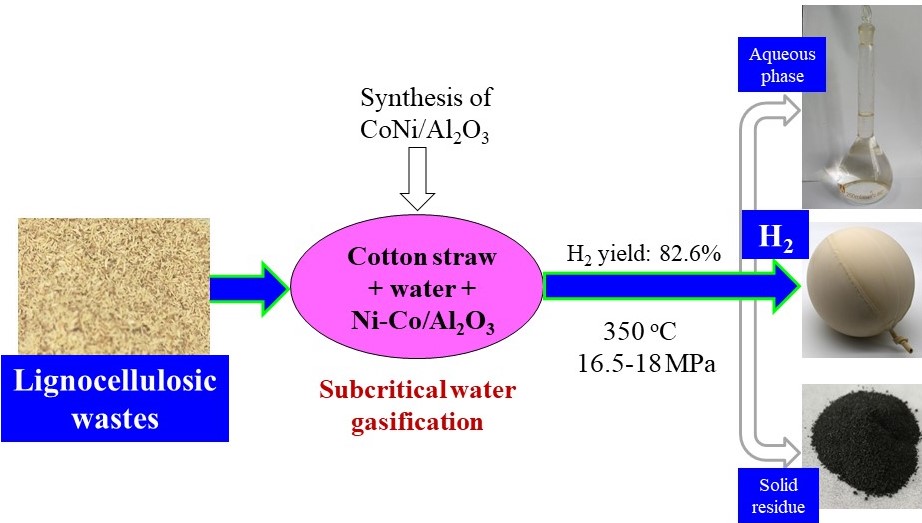

Nickel-based catalysts with different supports and cobalt loadings were synthesized for hydrothermal gasification of cellulose 350 oC. The activity of Ni catalysts was found in the order of Al2O3 > spent bleaching clay ash > SiO2 with H2 yield of 80.6%, 69.0% and 57.0% and the prepared catalyst using Al2O3 as the support showed the highest catalytic activity to produce H2. When 6 wt. % Co was added, H2 yield reached the maximum value of 88.4%, which was 1.44 times than that of 10Ni/Al2O3 catalyst without adding Co. Catalysts were characterized by NH3-TPD, TPR, XRD, BET and XPS, showing that Ni-Co alloy formation promoted H2 production. Furthermore, the effect of parameters such as feedstock usage and residence time were also investigated systematically with 10Ni-6Co/Al2O3 catalyst and the results indicated that the optimal yield of H2 at 94.9% was obtained at the conditions of 0.5g cellulose usage and 20 min residence time. Finally, the study about different lignocellulosic wastes (rice straw, peanut shells and cotton straw) with the increase in H2 yield by 51.4, 76.0 and 67.8 times and cotton straw obtained the highest H2 yield of 82.6%. Ni-Co/Al2O3 catalysts enhanced hydrothermal gasification of lignocellulosic wastes.

Related results were accepted in J Supercrit Fluids:

J Sun, L Xu, GH Dong, S Nanda, H Li, Zhen Fang*, JA Kozinski, AK Dalai, Subcritical water gasification of lignocellulosic wastes for hydrogen production with Co modified Ni/Al2O3 catalysts. J Supercrit Fluids, https://doi.org/10.1016/j.supflu.2020.104863 , 162, 104863, 2020.

Catalytic hydrothermal gasification of cotton straw with H2 yield of 82.6% over NiCo/Al2O3 catalyst at 350 oC and 20 min.(NiCo/Al2O3催化剂在350 oC和20 min条件下催化棉花秸秆水热气化, H2产率为82.6%。)

CoNi/Al2O3催化剂在亚临界水中气化木质纤维素废弃物制氢

最近,硕士生孙杰在方老师的指导下,与加拿大滑铁卢大学JA Kozinski院士和萨斯卡彻温大学AK Dalai院士合作,在国际学术期刊J Supercrit Fluids发表以Co改性Ni/Al2O3催化剂从木质纤维素废弃物中制取氢气的研究性论文。

合成了具有不同载体和钴载量的镍基催化剂,用于350 oC条件下纤维素的水热气化。 Ni催化剂的活性根据载体来排序依次为Al2O3、SBC ash (废白土灰)、SiO2,对应的H2产率分别为80.6%,69.0%和57.0%,且以Al2O3作为载体制备的催化剂具有最高的产氢催化活性。当Co的负载量为6 wt. %时,H2产率达到最大值,为88.4%,是不添加Co的10Ni/Al2O3催化剂H2产率的1.44倍。NH3-TPD,TPR,XRD,BET和XPS等特征分析,表明Ni-Co合金的形成促进了H2的产生。此外,还以10Ni-6Co/Al2O3作为催化剂研究了原料用量和停留时间等参数的影响,结果表明,在纤维素用量和停留时间分别为0.5 g和20 min的条件下,H2产率进一步提高到94.9%。最后,对不同木质纤维素废弃物(水稻秸秆、花生壳和棉花秸秆)的气化进行了研究,H2产率分别提高了51.4、76.0和67.8倍,而棉秸秆获得最高的H2产量为82.6%。 Ni-Co/Al2O3催化剂促进了木质纤维素废弃物水热气化产氢。详情可见:

J Sun, L Xu, GH Dong, S Nanda, H Li, Zhen Fang*, JA Kozinski, AK Dalai, Subcritical water gasification of lignocellulosic wastes for hydrogen production with Co modified Ni/Al2O3 catalysts. J Supercrit Fluids, https://doi.org/10.1016/j.supflu.2020.104863 , 162, 104863, 2020.