MOF催化剂制备生物柴油: Microwave-assisted one-step production of biodiesel from waste cooking oil by magnetic bifunctional SrO–ZnO/MOF catalyst

Microwave-assisted one-step production of biodiesel from waste cooking oil by magnetic bifunctional SrO–ZnO/MOF catalyst

Recently, master student Mr. Jian Yang supervised by Prof. Zhen Fang published a research article in Journal of Cleaner Production about synthesizing bifunctional SrO–ZnO/MOF catalyst for biodiesel production from waste cooking oil.

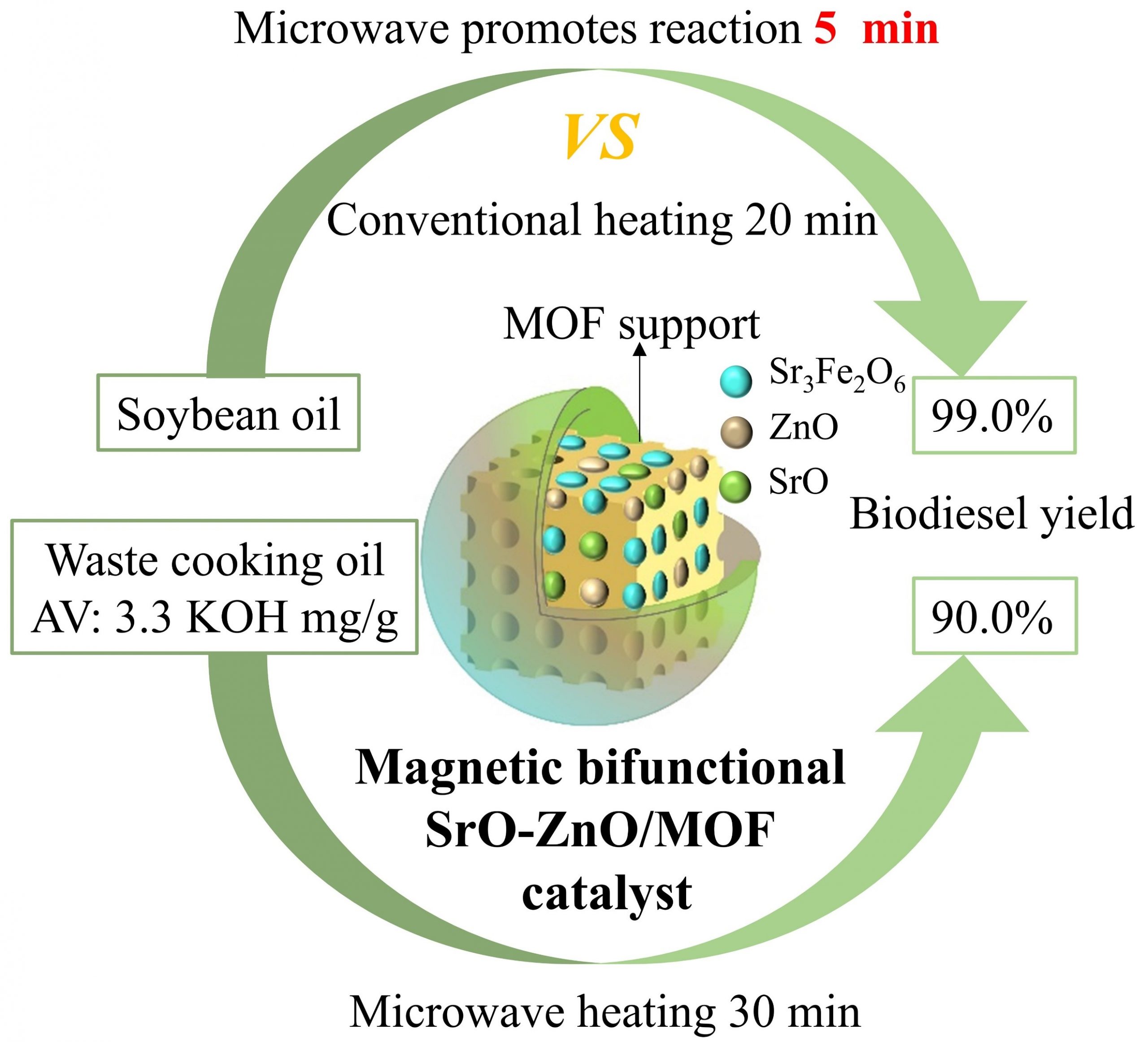

Magnetic bifunctional SrO–ZnO/MOF catalyst supported on metal-organic framework (MOF) was synthesized for one-step biodiesel production from high acid value oils. The catalyst presented both basicity (2.84 mmol/g) and acidity (0.02 mmol/g) due to active components of Sr3Fe2O6 and ZnO. MOF support increased catalyst specific surface by 3.7 times and provided Fe3O4 component for magnetic separation. The highest soybean biodiesel yield of 99.5% was obtained at 80 ℃ with 3 catalyst cycles. Microwave heating significantly reduced reaction time from 20 min to 5 min at 99.0% biodiesel yield and 80 ℃. The catalyst was highly active and resistant to free fatty acids with biodiesel yield of 90.0% from waste cooking oil (AV of 3.3 mg KOH/g) at longer reaction time of 30 min. SrO–ZnO/MOF has potential application in biodiesel industry.

Related results were accepted in Journal of Cleaner Production.

Jian Yang, Wen-Jie Cong, Zongyuan Zhu**, Zheng-diao Miao, Yi-Tong Wang***, Michael Nelles, Zhen Fang*. Microwave-assisted one-step production of biodiesel from waste cooking oil by magnetic bifunctional SrO–ZnO/MOF catalyst. Journal of Cleaner Production 395 (2023) 136182. https://doi.org/10.1016/j.jclepro.2023.136182

Acid/base SrO-ZnO/MOF catalyst for one-step biodiesel production from waste cooking oil in 30 min with microwave radiation. (双功能SrO-ZnO/MOF催化剂在微波辅助加热下30分钟从废弃食用油中一步生产生物柴油。)

微波辅助磁性双功能SrO–ZnO/MOF催化剂一步法从废弃食用油中制备生物柴油

最近,硕士生杨剑在方真教授的指导下,在国际学术期刊Journal of Cleaner Production (Q1, IF 11.072)发表一篇关于使用双功能磁性SrO–ZnO/MOF催化剂从废弃食用油中制备生物柴油的研究性论文。

合成了由金属有机骨架(MOF)负载的磁性双功能SrO–ZnO/MOF催化剂,用于高酸值油一步制备生物柴油。Sr3Fe2O6和ZnO为催化剂提供碱度(2.84mmol/g)和酸度(0.02mmol/g)。MOF载体将催化剂比表面积提高了3.7倍,形成的Fe3O4赋予催化剂磁性。催化豆油制备生物柴油的产率在80 ℃下达到99.5%,通过简单的磁性分离催化剂可循环使用3次。微波加热显著缩短了反应时间,在相同的生物柴油产率(99.0%)下,传统油浴加热需要20 min,而微波加热将反应时间缩短3倍,仅用了5 min。该催化剂具有高度活性,并且对游离脂肪酸具有抗性,在80 ℃下反应30分钟,催化酸值为3.3 mg KOH/g的废弃食用油的生物柴油产率达到90.0%。SrO–ZnO/MOF催化剂在生物柴油工业中具有潜在应用。

结果发表在Journal of Cleaner Production

Jian Yang, Wen-Jie Cong, Zongyuan Zhu**, Zheng-diao Miao, Yi-Tong Wang***, Michael Nelles, Zhen Fang*. Microwave-assisted one-step production of biodiesel from waste cooking oil by magnetic bifunctional SrO–ZnO/MOF catalyst. Journal of Cleaner Production 395 (2023) 136182. https://doi.org/10.1016/j.jclepro.2023.136182