2025大会特邀报告Invited plenary lecture on Int’l Conf. on Green & Low Carbon Utilization of Biomass

星期二, 8 7 月, 2025

大会特邀报告Invited plenary lecture

Invited plenary lecture on Int’l Conf. on Green & Low Carbon Utilization of Biomass

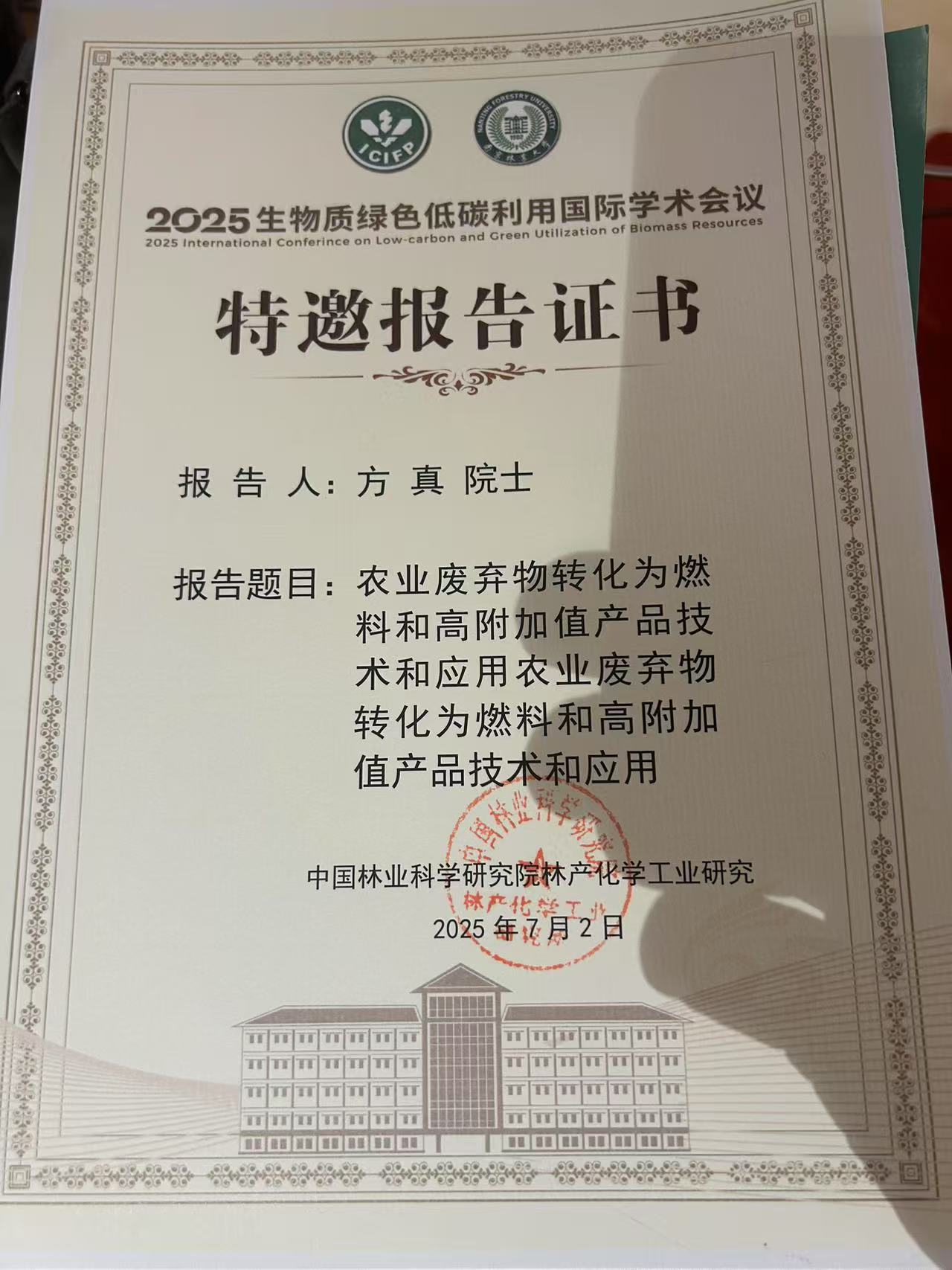

Zhen Fang, “Techniques and applications of converting agricultural biomass to biofuels and high value-added products”, The Int’l Conf. on Green & Low Carbon Utilization of Biomass July 1-4, 2025 Nanjing, Jiangsu, Institute of Chemical Industry of Forestry Products, Chinese Academy of Forestry (Invited plenary lecture).

方真,“农业废弃物转化为燃料和高附加值产品技术和应用“,生物质绿色低碳利用国际学术会议,中国林业科学院林产品化学工业研究所,大会特邀报告,2025年07月1-4日,江苏∙南京。

大会全体合影Group Photo for all delegates

大会报告Invited plenary lecture

大会报告Invited plenary lecture

大会报告证明Certificate for the Invited plenary lecture

与年青教师和研究生合影with a young prof. and a master student