深入企业Prof. Zhen Fang visited Bioenergy Enterprises

星期六, 15 11 月, 2025Prof. Zhen Fang visited Bioenergy Enterprises

登高观察对岸Climbing high to observe the opposite bank in Ningbo

Professor Zhen Fang went to Ningbo to seek cooperation in-depth with bioenergy enterprises

At the invitation of the Ningbo Agriculture Bureau, Professor Zhen Fang visited relevant bioenergy enterprises in Ningbo from September 21st to 23rd, 2025. On the morning of September 21, 2025 at 9:49 am, the sky was clear and cloudless. Professor Zhen Fang departed from Nanjing with great excitement and sat at the window of the southbound Ningbo high-speed railway train. He arrived in Ningbo at around 12:00 noon and met with the vice-mayor. After lunch, take a short break and drove with the leaders of the Agriculture Bureau to Mingzhou Thermal Power Co., Ltd. of Ningbo Energy Group to explore the profitability and sustainable development of bioenergy enterprises of the straw power generation and bamboo gas & charcoal co-production workshops with company leaders and engineers. In the next morning, he together with the leaders of the Agriculture Bureau went to the factory (owned by Decheng Biotechnology Company in Hangzhou) in Xiangshan, Ningbo. The company is building a straw-based polylactic acid factory using thermophilic anaerobic bacteria modified in Germany for hydrolysis and co-fermentation to produce lactic acid. Degradable polylactic acid has been tested in Germany, and the estimated cost is slightly higher than that from grain-based polylactic acid. Prof. Fang personally hopes that industrialization can be successful and it can replace petroleum-based plastics. After lunch, Prof. Fang and his delegation were invited to visit the Ningbo Academician Center and then went to Cixi city. The next morning, Prof. Fang had a discussion with young teachers from the School of Science and Technology at Ningbo University about his research experience. After lunch, he stepped onto the bullet train window heading north to Nanjing and ended his trip to Ningbo.

方真教授赴宁波深入生物能源企业寻求合作

应宁波农业局邀请,方真教授于2025年9月21日-23日赴宁波调研相关生物能源企业。 2025年9月21日上午9:49 am,天空晴朗,万里无云,方真教授怀着无比激动的心晴从南京出发,坐往南下宁波高铁窗口,中午12:00抵宁波并会见市领导。午饭后,稍事休息,与农业局领导一同驱车前往宁波能源集团明州热电有限公司,深入秸秆发电以及竹块炭气联产车间与企业领导和工程师探讨生物能源企业盈利情况和可持续发展。第二天一早,与农业局领导一道深入宁波象山,一正在建一秸秆产聚乳酸工厂(位于杭州的德城生物公司)。公司用德国改造的嗜热厌氧菌水解可并发酵产乳酸,在德国已中试产可降解聚乳酸,目前估算成本稍高粮食基聚乳酸,方老师个人愿望产业化能成功并可取代石油基塑料。午饭后,方老师一行应邀参访宁波院士中心,随后赴慈溪。第二天一早和宁波大学科技学院青年教师座谈科研体会,午饭后,踏上了北上南京的列车窗口结束了宁波之行。

深入宁波能源集团明州热电有限公司秸秆发电车间In-depth visiting the straw power generation workshop in Mingzhou Thermal Power Co., Ltd. under Ningbo Energy Group

深入明州热电有限公司竹块炭气联产车间In-depth visiting the char and gas co-production from bamboo chips workshop in Mingzhou Thermal Power Co., Ltd.

深入明州热电有限公司产品展示车间Visiting the products demonstration workshop in Mingzhou Thermal Power Co., Ltd.

深入宁波象山德城生物公司聚乳酸工厂In-depth investigation of the polylactic acid factory in Ningbo Xiangshan Decheng Biotechnology Co., Ltd

深入象山德城生物公司聚乳酸工厂In-depth investigation of the polylactic acid factory in Xiangshan Decheng Biotechnology Co., Ltd

深入象山德城生物公司聚乳酸车间In-depth investigation of the polylactic acid workshop in Xiangshan Decheng Biotechnology Co., Ltd

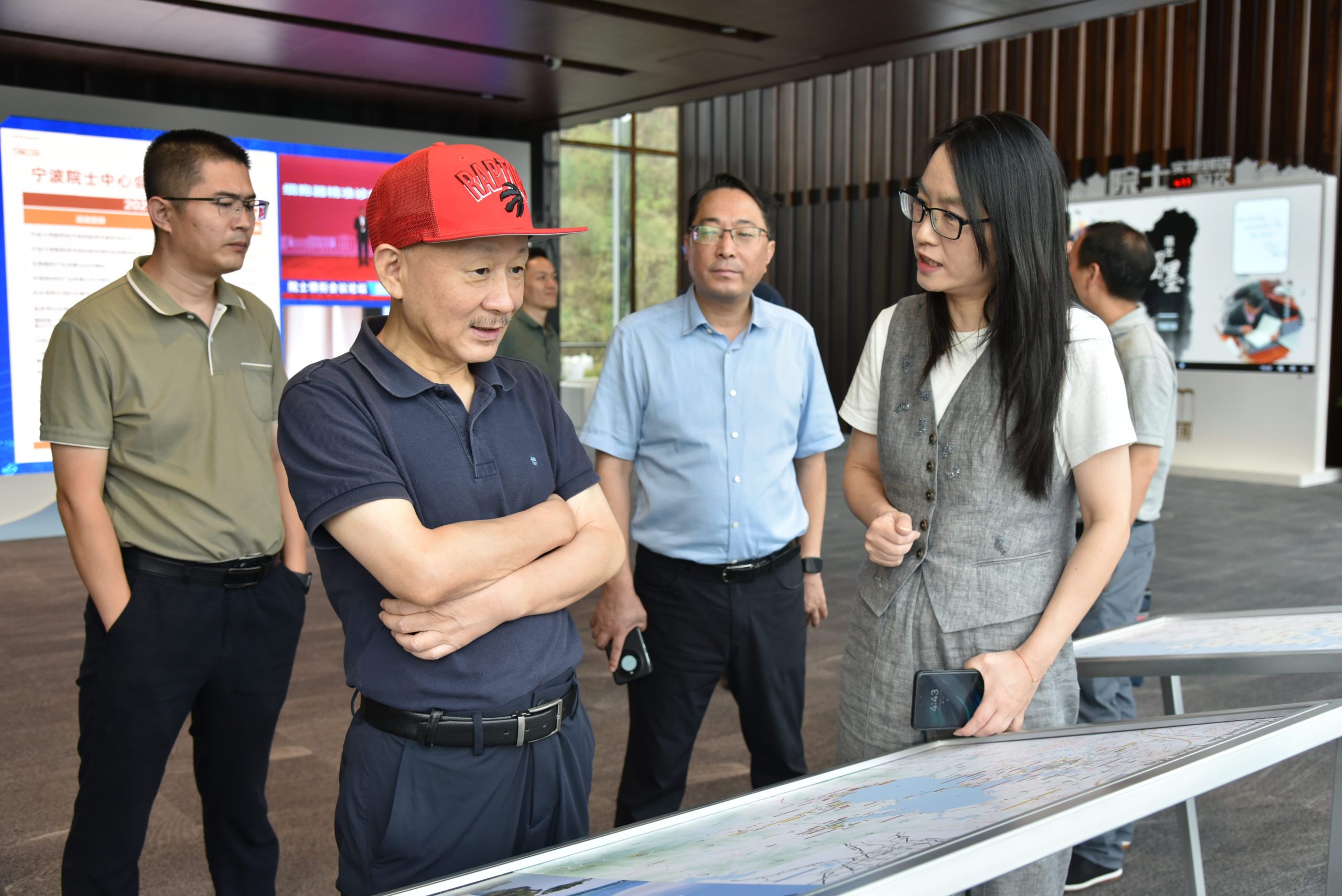

参访宁波院士中心Visit Ningbo Academician Center

https://ishare.ifeng.com/c/s/v002NUxWO–fZA7dKebChG9xBkBKOk7ZK3o4tej9igRkm–i0__