Biodiesel production directly from oils with high acid value by magnetic Na2SiO3@Fe3O4/C catalyst and ultrasound

星期二, 17 3 月, 2015Biodiesel production by transesterification with homogeneous catalysts (e.g, sodium methoxide, sodium or potassium hydroxide) is one of the most common methods, but it is difficult to recycle due to they are dissolved in methanol and glycerol mixture. So, researchers have focused on finding suitable heterogeneous solid catalysts, such as K2CO3 supported activated carbon, CaO, Sr/MgO, MnO and TiO, to replace homogeneous liquid catalysts. However, solid base catalysts are easy to deactivate when low qualified oils with high acid value (AV) are used as raw materials due to soap formation.

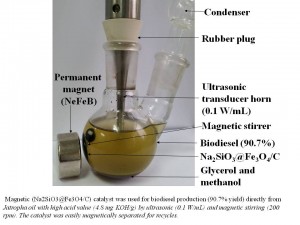

Mr. Zhang Fan, a PhD student, under the guidance of Professor Zhen Fang in Xishuangbanna Tropical Botanical Garden (CAS), prepared cheap and active magnetic heterogeneous catalyst (Na2SiO3@Fe3O4/C) for the production of biodiesel from oils with high acid value (AV) under ultrasonic (US) irradiation and magnetic stirring (MS). With the catalyst and assisted by US, soybean biodiesel yield reached > 90% in only 20 min (or at 318 K) and 97.9% under the optimal conditions. It was easily magnetically separated for 5 cycles with 94.9% recovery rate and biodiesel yield > 80% with both US and MS. The catalyst transesterified Jatropha oil with biodiesel yields of 94.7%, 93.2% and 83.5% at AV of 1.3, 4.8 and 7.3 (mg KOH/g) with US. High biodiesel yield (90.7%) was still achieved from high AV oil (4.8) at low US energy density (0.1 W/mL) and MS. The catalyst combined with US and MS can find practical application for direct production of biodiesel from oils with high AV, and recovered easily for recycles.

The results are published in fuel:

F Zhang, Zhen Fang*, YT Wang, Biodiesel Production Directly from Oils with High Acid Value by Magnetic Na2SiO3@Fe3O4/C Catalyst and Ultrasound, Fuel, 150, 370-377 (2015).

Na2SiO3@Fe3O4/磁性催化剂的制备及其用于超声波直接从高酸值油脂生产生物柴油

由于石化资源有限并且燃烧后二氧化碳浓度急剧升高,所以开发利用可再生的生物质燃料具有重要的价值和意义。生物柴油是一种清洁、可再生、碳中性并可替代石化柴油的液体燃料。利用均相催化剂(如:甲醇钠、氢氧化钾或氢氧化钠)通过酯交换反应制备生物柴油是最常用的方法,但是由于此类催化剂会溶解到甲醇和甘油中使得其难以循环再利用。所以研究人员一直努力寻找合适的非均相固体催化剂,例如碳载K2CO3、CaO、Sr/MgO、 MnO和TiO取代均相液体催化剂。但是碱性非均相固体催化剂由于皂化反应,不适宜用高酸值油(如废弃煎炸油、动物油脂和小桐子油)制备生物柴油。同时,与超声波辐射相比,在机械搅拌方式下,需要更长时间(如3 h)的酯交换反应制备生物柴油。

中国科学院西双版纳热带植物园生物能源组博士生张帆在方真研究员的指导下,成功合成了磁性非均相固体催化剂(Na2SiO3@Fe3O4/C),并利用该固体催化剂在超声波和机械搅拌条件下用于高酸值油脂制备生物柴油。实验结果表明:在20分钟45摄氏度的超声波辅助条件下大豆油得率高于90%(最优条件下可以达到97.9%),在机械搅拌和超声波辐射协同作用时,该催化剂循环五次后生物柴油得率仍然高于80%且催化剂回收率为94.9%。利用该催化剂催化转化不同酸值(1.3、4.8 和 7.3 mg KOH/g)小桐子油,其生物柴油得率分别为94.7%、93.2% 和 83.5%,并且在较低的超声波能量密度下(0.1 W/mL),高酸值小桐子油(4.8 mg KOH/g)的生物柴油得率仍然可以达到90.7%。结合机械搅拌和超声波辅助条件,Na2SiO3@Fe3O4/C可以实现高酸值原料油直接转化制备生物柴油。相关研究成果发表在国际著名能源期刊Fuel上:

F Zhang, Zhen Fang*, YT Wang, Biodiesel Production Directly from Oils with High Acid Value by Magnetic Na2SiO3@Fe3O4/C Catalyst and Ultrasound, Fuel, 150, 370-377 (2015).

图为可磁性分离的催化剂Na2SiO3@Fe3O4/C用于小桐子生物柴油制备