Application of ultrasonic energy in biofuels

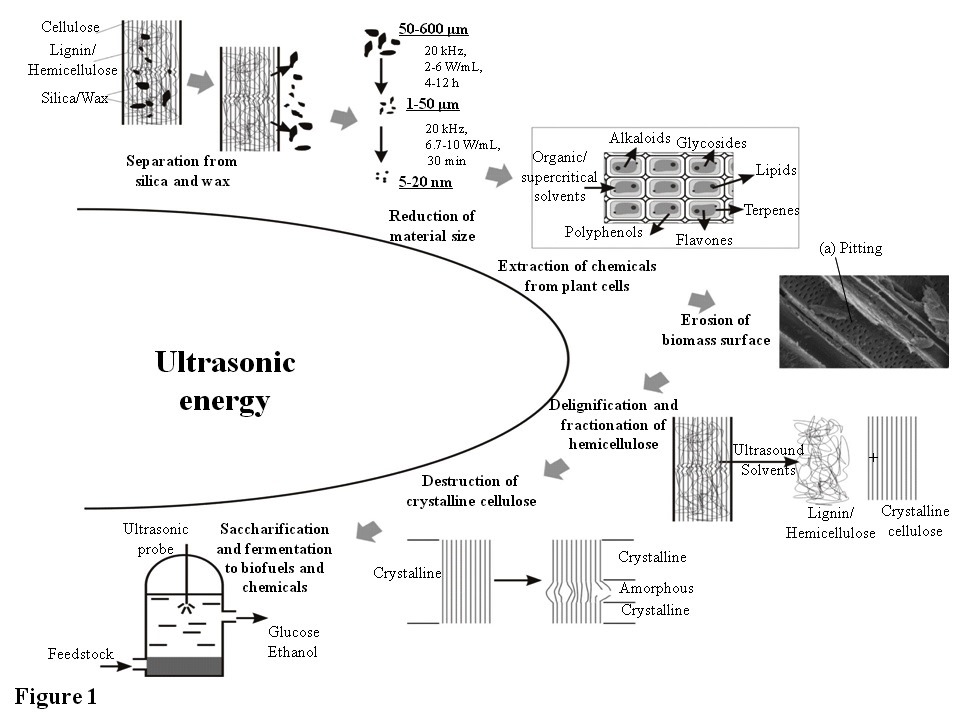

The conversion of green, cheap and renewable biomass materials into biofuels through thermochemical and biochemical methods is one of the key route to provide sustainable energy in future. The introduction of ultrasonic energy in biomass conversion could destroy the recalcitrance structure of lignocellulosic biomass at room temperature, facilitate the separation of complicated composition in raw materials, turn heterogeneous reactions into homogeneous or at least quasi- homogeneous reactions, and therefore essentially remove barriers that limited the efficiency and selectivity in biomass conversion. Ultrasonic wave has some special physical properties. It can accumulate energy by acoustic cavitation, and then release them instantaneously by the collapse of cavitational bubbles within several microseconds. The intensity of released energy can be enough to break down any chemical linkage, destroy the limit in multiphase interface and enhance the mass transfer and heat transfer during the reactions. Therefore, sonochemical treatment could efficiently destroy biomass structure, improve the mixing and reactions of biomass materials, however, the selectivity of biomass reactions is not remarkably altered.

Although sonication had been used in many research fields related to biofuels, such as the pretreatment, saccharification, and fermentation of lignocellulose, biodiesel synthesis, pretreatment and chemical reactions of microalgae, but actually, not all processes using ultrasonic energy was economic or with high efficiency. The proper coupling of the energy from ultrasonic activation and that from biomass reactions, which could results in positive or even better benefit in energy output and process economics, is still the critical problem for the application of sonication in biofuel technologies.

Dr. Jia Luo and Professor Zhen Fang, from Research Group of Biomass Energy in Xishuangbanna Tropical Botanical Garden, Chinese Academy of Sciences, reviewed the progresses on the application of ultrasound in biofuels, with the main attentions on the progresses and trends in the fractionation and conversion of lignocellulose, biodiesel synthesis, as well as pretreatment and chemical reactions of microalgae, with low-frequency ultrasound at 20-50 kHz. It demonstrated that ultrasonic auxiliary did not substantially change the mechanism of chemical reactions, but could remarkably accelerate reactions, save reaction time, and even improve the efficiency and selectivity in biomass conversion by inhibiting secondary reactions. It was necessary to determine the way and the degree of incorporating sonication, change the design of novel sonochemical reactors, optimize the ultrasonic processing parameters, according to the energy demand for certain chemical processing. Sonication technology was also suggested to be combined with other methods such as solvents, catalysts and microwave to lessen the energy cost of using sonication, and achieve a greater benefit in energy output and process economics. At the last of the paper, the authors discussed the combination of sonication with solid catalysts and enzymes, discussed the problems related to the process economics in different biomass processing and reactions, and gave some constructive suggestions. The authors also gave some descriptions on the progresses on ultrasound-assisted emulsification of raw bio-oil and real time monitoring of biomass reactions with high-frequency ultrasound technologies.

The review paper (Jia Luo, Zhen Fang, Richard L. Smith Jr. Ultrasound-enhanced conversion of biomass to biofuels.) was accepted and already published on line.

URL: http://www.sciencedirect.com/science/article/pii/S036012851300052X

Mechanistic effects of ultrasonic energy in lignocellulose pretreatment and conversion