化学压缩处理秸秆Insights into the role of chemical-assisted densification in structural deconstruction and enzymatic hydrolysis enhancement of corn stover

10 1 月, 2026Insights into the role of chemical-assisted densification in structural deconstruction and enzymatic hydrolysis enhancement of corn stover

Recently, under the supervision of Assoc. Prof. Chun-xiao Gong and Prof. Zhen Fang, MSc student Mr. Ting-yu Bi collaborated with MSc student Mr. TT Yang from Nanjing Forestry University and published a research article in Renewable Energy on the insights into the role of chemical-assisted densification in structural deconstruction and enzymatic hydrolysis enhancement of corn stover.

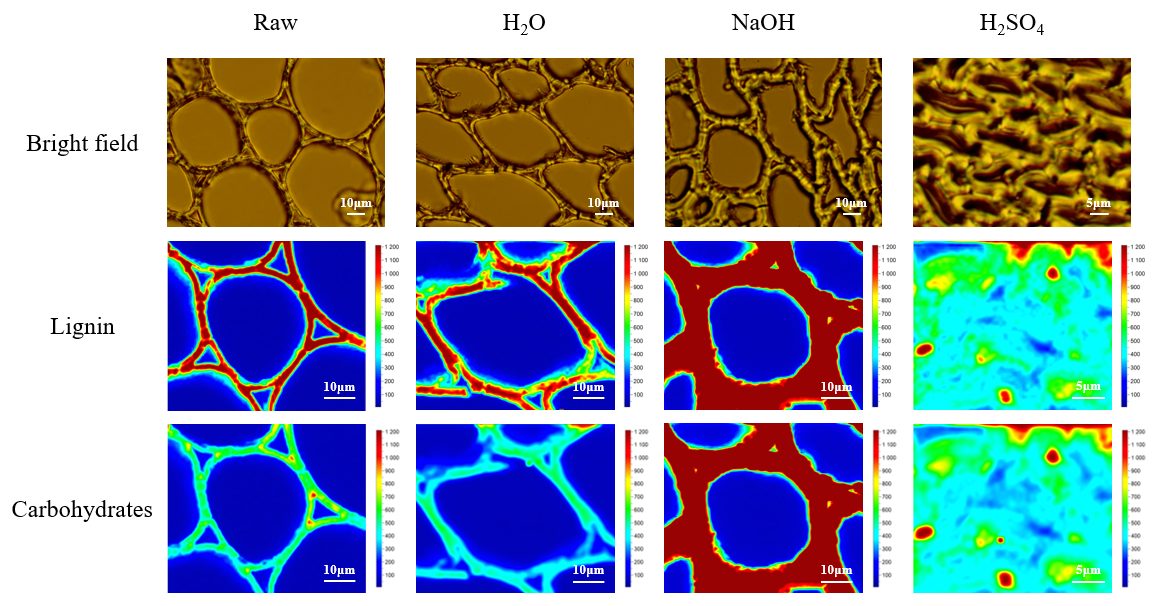

Densification facilitates the utilization of lignocellulosic biomass by overcoming its limitations of low density and associated processing costs. In this study, acid- and alkali-assisted pelletization of corn stover was performed to investigate the synergistic effects of chemicals and mechanical compression on the physicochemical properties of the pellets and their enzymatic hydrolysis. Results from confocal Raman microscopy revealed that densification caused significant rupture and collapse of plant cell walls. The combined effects of chemicals, pressure, and heat during pelletization reduce biomass particle size and effectively degrade its components. Pelletization also lowers the water absorption capacity of biomass, enabling enzymatic hydrolysis slurries to stay well-mixed at high solid loadings. Acid-assisted pelletization hydrolyzed hemicelluloses into xylose and xylooligosaccharides, whereas alkali-assisted pelletization primarily degraded lignin. Enzymatic hydrolysis of pellets without further pretreatment demonstrated that H2SO4-treated pellets achieved glucose and xylose yields of 48.2 % and 72.8 %, respectively, while NaOH-treated pellets yielded 76.8 % glucose and 63.8 % xylose. These findings could facilitate the application of acid- and alkali-assisted biomass pelletization in large-scale biorefineries.

Results were published in Renewable Energy:

TY Bi, TT Yang, ZY Ju, CY Dong, N Li, LJ Xu, W Chen, Zhen Fang, CX. Gong*, Insights into the role of chemical-assisted densification in structural deconstruction and enzymatic hydrolysis enhancement of corn stover, Renewable Energy, 258 (2026), 124924. https://doi.org/10.1016/j.renene.2025.124924

Raman images of the lignin and carbohydrates distribution in the raw corn stover, CSP-H2O, CSP-NaOH, and CSP-H2SO4原始玉米秸秆及其压缩成型CSP-H2O、CSP-NaOH和CSP-H2SO4样品质素与碳水化合物分布的拉曼图像

化学辅助压缩成型在玉米秸秆结构解构与酶解增强中的作用机制解析

最近,在龚春晓副教授和方真教授指导下,硕士生毕庭喻先生与南京林业大学硕士生杨天天先生合作,在《Renewable Energy》上发表了一篇关于化学辅助压缩成型在玉米秸秆结构解构与酶解增强中的作用机制解析的研究文章。

压缩成型通过克服木质纤维素生物质低堆积密度及其相关加工成本等限制,有助于促进其高效利用。在本研究中,对玉米秸秆进行了酸辅助和碱辅助造粒,以探究化学物质与机械压缩对颗粒理化性质及其酶解性能的协同作用。共焦拉曼显微镜结果显示,致密化会导致植物细胞壁发生显著的破裂与塌陷。造粒过程中化学物质、压力和热量的共同作用可降低生物质的颗粒尺寸,并有效降解其组分。造粒还可降低生物质的吸水能力,使酶解浆料在高固体含量条件下仍能保持良好混合状态。酸辅助造粒将半纤维素水解为木糖和木寡糖,而碱辅助造粒则主要降解木质素。未经进一步预处理的颗粒酶解结果显示,H₂SO₄ 处理颗粒的葡萄糖和木糖产率分别达到 48.2% 和 72.8%,而 NaOH 处理颗粒的葡萄糖和木糖产率分别为 76.8% 和 63.8%。这些研究结果有助于推动酸辅助和碱辅助生物质造粒在大规模生物质精炼厂中的应用。

结果发表在Renewable Energy:

TY Bi, TT Yang, ZY Ju, CY Dong, N Li, LJ Xu, W Chen, Zhen Fang, CX. Gong*, Insights into the role of chemical-assisted densification in structural deconstruction and enzymatic hydrolysis enhancement of corn stover, Renewable Energy, 258 (2026), 124924. https://doi.org/10.1016/j.renene.2025.124924