2024方真教授主旨/特邀报告Selected Keynote/Invited Lectures

星期二, 31 12 月, 2024

方真老师认真学习,努力进步Study diligently and strive for progress

2024 方真教授主旨/特邀报告Selected Keynote/Invited Lectures

1.Zhen Fang, “Techniques and Applications of Converting Agricultural and Forestry Biomass to Biofuels and High Value-Added Products”, Energy and Environment Branch, 2024 Academic Annual Meeting, China Agricultural Mechanization Society, Aiming to Build a Low-Carbon Circular Agriculture System and Promote Green Development in Agriculture and Rural Areas, Shandong University of Technology, November 22-25, 2024, Zibo, Shandong.

方真,“农林生物质转化为燃料和高附加值产品技术和应用”,2024年中国农业机械学会学术年会能源环境分会, 构建低碳循环农业体系促进农业农村绿色发展,山东理工大学,2024年11月22-25日,山东∙淄博。

易维民副校长合影, with Prof. Wei-ming Yi, former vice-president in Exterior of the 2024 China Agricultural Machinery Annual Conference

演讲中, giving lecture

2024中国农机年会大会外景Exterior of the 2024 China Agricultural Machinery Annual Conference

2.Zhen Fang, “Biochar Supported Bifunctional Catalysts for One-Pot Production of Biodiesel from Waste Oils”, UK-China-ASEAN Net-Zero Workshop On-line, November 12, 2024, Liverpool, UK

方真,“用于废油一锅法生产生物柴油的生物炭负载双功能催化剂”,2024江苏-英国-东南亚零碳线上研讨会(线上),2024年11月12日,利物浦∙英国。

Speech in UK-China-ASEAN Net-Zero Workshop on-line in Ningbo线上演讲

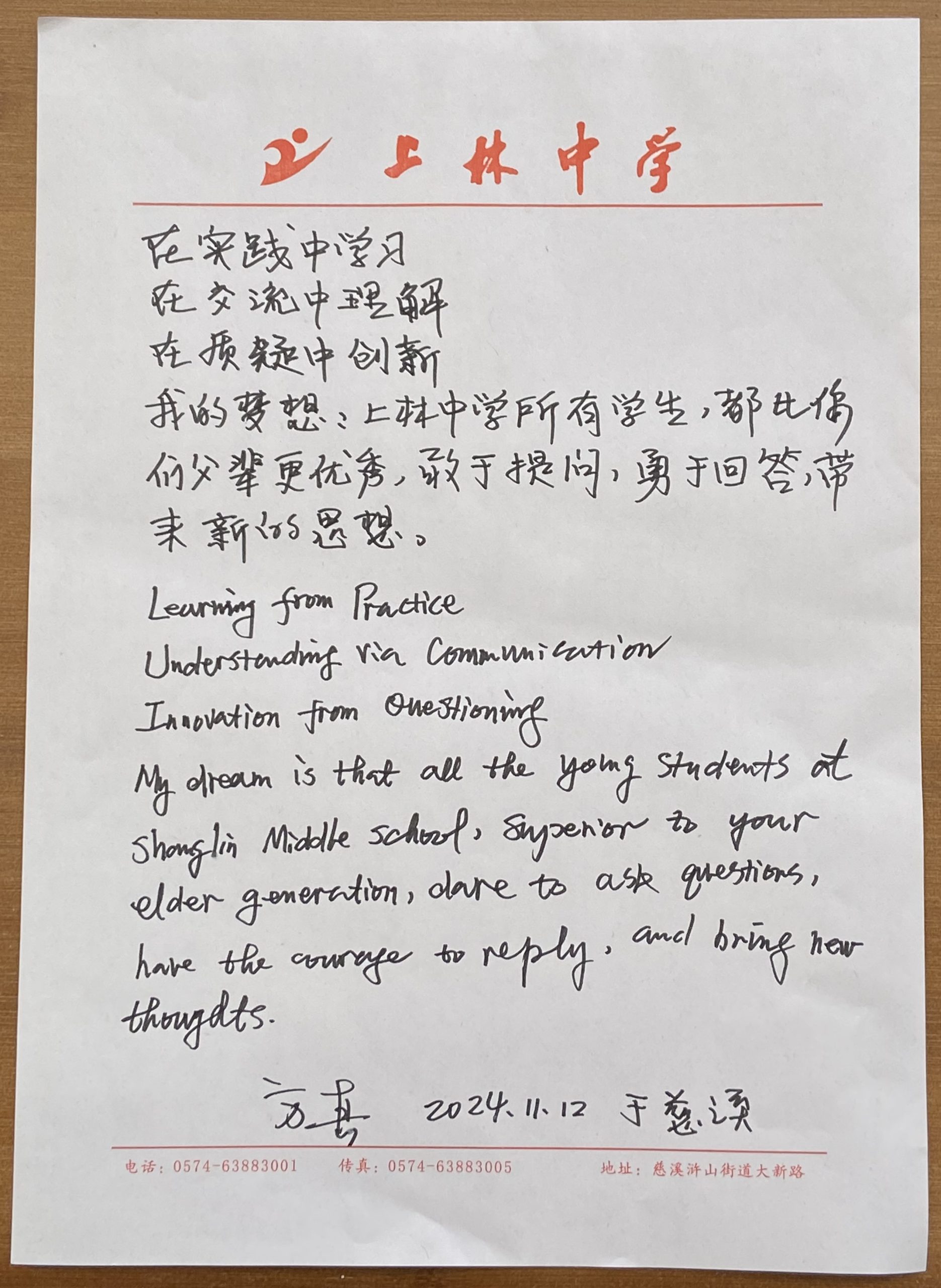

3.Zhen Fang, “My Experience in Learning and Research”, Shangshan Lecture, Cixi Shanglin Middle School, November 11, 2024, Ningbo, Zhejiang.

上林中学演讲:方真,“院士成长心路历程”,上善大讲堂,慈溪上林中学,2024年11月11日,浙江∙宁波慈溪。

演讲中in Speech

演讲后互动答疑环节After lecture in Q&A session

演讲后互动答疑环节After lecture in Q&A session

和杨俊进校长等学生合影with Principals and students after lecture

方真教授的个人愿望Prof. Zhen Fang personal wish

上林中学演讲:

https://mp.weixin.qq.com/s/VMVGhKCgntSP6BxTk0RUBQ

4.Zhen Fang “Technology and Application of Agricultural Waste Conversion into Fuel and High Value-Added Products”, College of Biosystems Engineering and Food Science, Zhejiang University, May 14, 2024, Hangzhou, Zhejiang.

方真,“农业废弃物转化为燃料和高附加值产品技术和应用“,浙江大学生物系统工程和食品科学学院, 2024年05月14日,浙江∙杭州。

After lecture with Prof Yi-bin Ying, former Vice-president 应义斌教授(原浙大副校长)

After lecture with Profs Ying,Ramaswamy (McGill) and Zhu应义斌副校长,Hosahalli S. Ramaswamy院士(麦吉尔大学教授)和朱松明院长合影