工程院大会(年会)Prof. Zhen FANG attended 2024 CAE Annual Conference & Induction Ceremony of New Fellows

星期一, 17 6 月, 2024

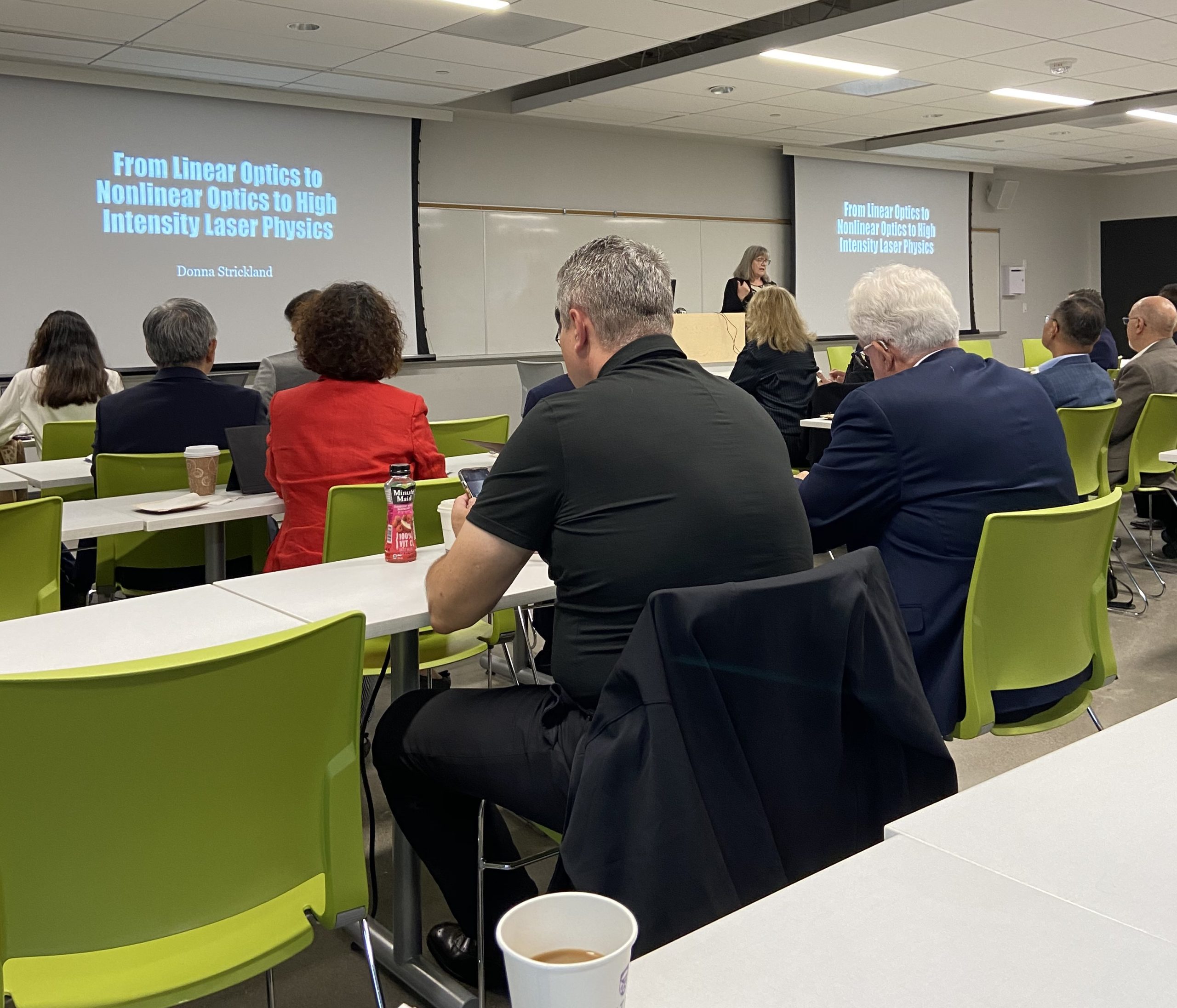

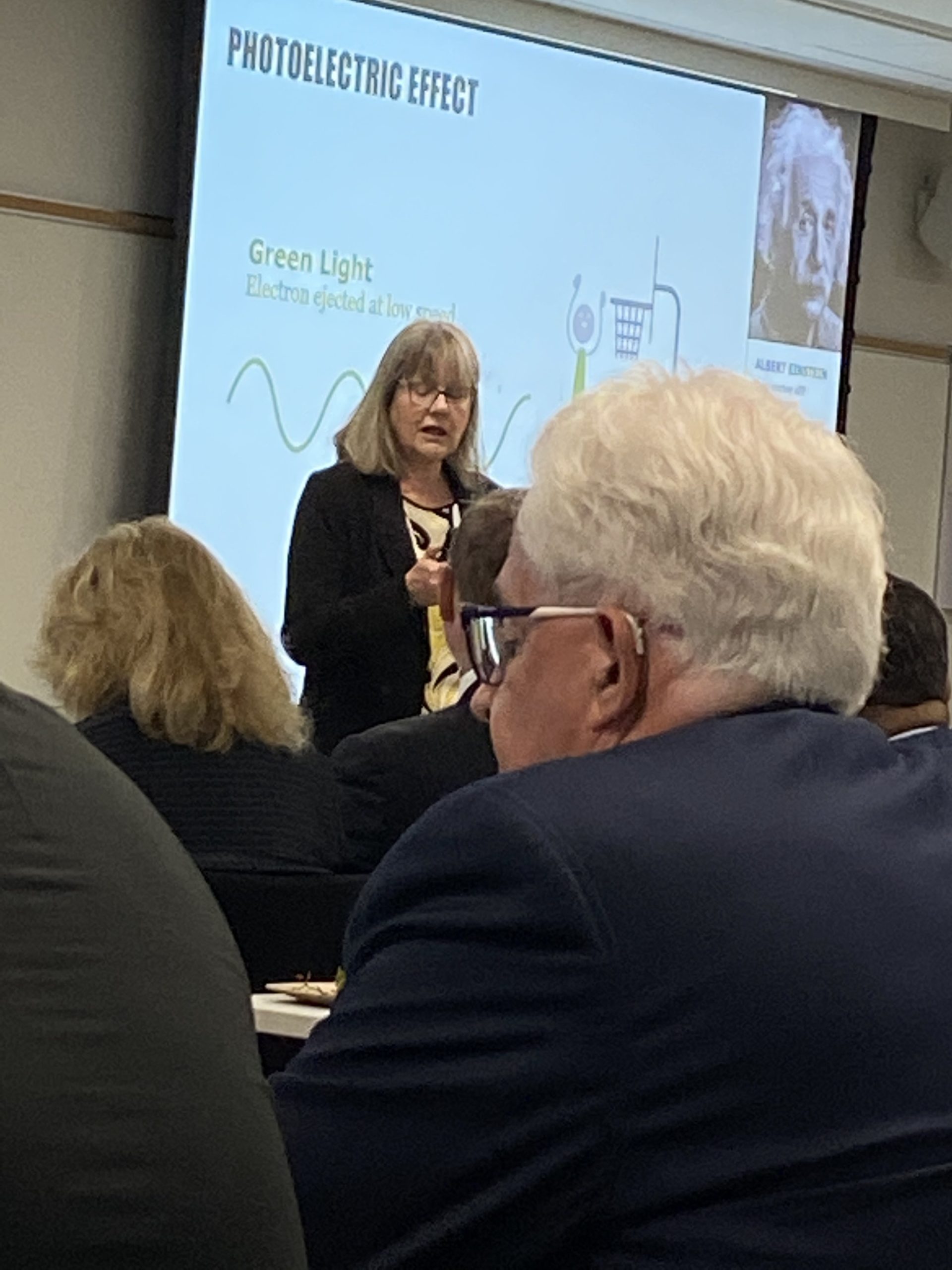

Prof. Donna Strickland (Waterloo), the Nobel Laureate (2018, Physics) delivering a keynote lecture in the morning of May 28 (滑铁卢大学教授2018年物理诺奖得主唐娜·斯特里克兰院士主题报告)

Prof. Zhen FANG attended 2024 CAE Annual Conference & Induction Ceremony of New Fellows

From May 26 to June 5, 2024, Prof. Zhen FANG visited Canada and USA, attended 2024 CAE (Canadian Academy of Engineering: https://www.cae-acg.ca/) Annual Conference & Induction Ceremony in London (May 27-29), visited McGill (https://www.mcgill.ca/) in Montreal (May 30-June 1) and New York University (NYU, https://www.nyu.edu/) (June 2-4).

The program included several panel presentations and discussions on important issues:

- AI/ML: The Disruptive Force Reshaping Engineering Disciplines

- Quantum Computing: Unleashing New Potentials and Challenges in Engineering

- From Lab to Market: Translating Cleantech Innovations into Practical Applications

- The next-generation batteries for EVs

- Infrastructure: energy and carbon emissions reduction

- Roadmap for Resilient Building

- The changing nature of severe summer storms and impact on engineering design

Prof. Zhen Fang in the morning of May 28(方真老师出席5月28日的大会)

Profs. Donna Strickland and Zhen Fang in the morning of May 28 (大会休息期间,唐娜·斯特里克兰院士和方真老师合影)

大会晚宴Gala Dinner

方真老师出席加拿大工程院大会(年会)暨新院士入职典礼

2024年5月26日至6月5日,方真老师访问加拿大和美国,出席2024 CAE(加拿大工程院:https://www.cae-acg.ca/)年度会议暨新院士入职典礼(伦敦,5月27-29日),随后访问麦吉尔大学(https://www.mcgill.ca/)(蒙特利尔,5月30日至6月1日)和纽约大学(https://www.nyu.edu/)(6月2-4日)。

大会包括几个关于重要问题的报告和小组讨论:

- AI/ML:颠覆性力量重塑工程学科

- 量子计算:释放工程中的新潜力和挑战

- 从实验室到市场:将清洁技术创新转化为实践应用

- 电动汽车的下一代电池

- 基础设施:减少能源和碳排放

- 弹性建筑路线图

- 严重夏季风暴的性质变化及其对工程设计的影响

Keynote Speech (大会主旨报告)

McGill sci road to the top of Royal Mount (通往皇家山顶的麦吉尔科学之路)

Prof. Zhen Fang visited Prof. CJ Li’s Lab at McGill in Montreal (麦基尔大学CJ 李庆军院士实验室)

Prof. Zhen Fang visited NYU (纽约大学一角)

Prof. Zhen Fang in the library at NYU(纽大图书馆)

Prof. Zhen Fang in the library at NYU(纽大图书馆)