Misses Jing-jing Guo, Yu-rou Wang, Hong-li Ma, Wan-ying Qiu and Mr. Guo-qiang Zhu successfully defended their Doctoral and Master theses

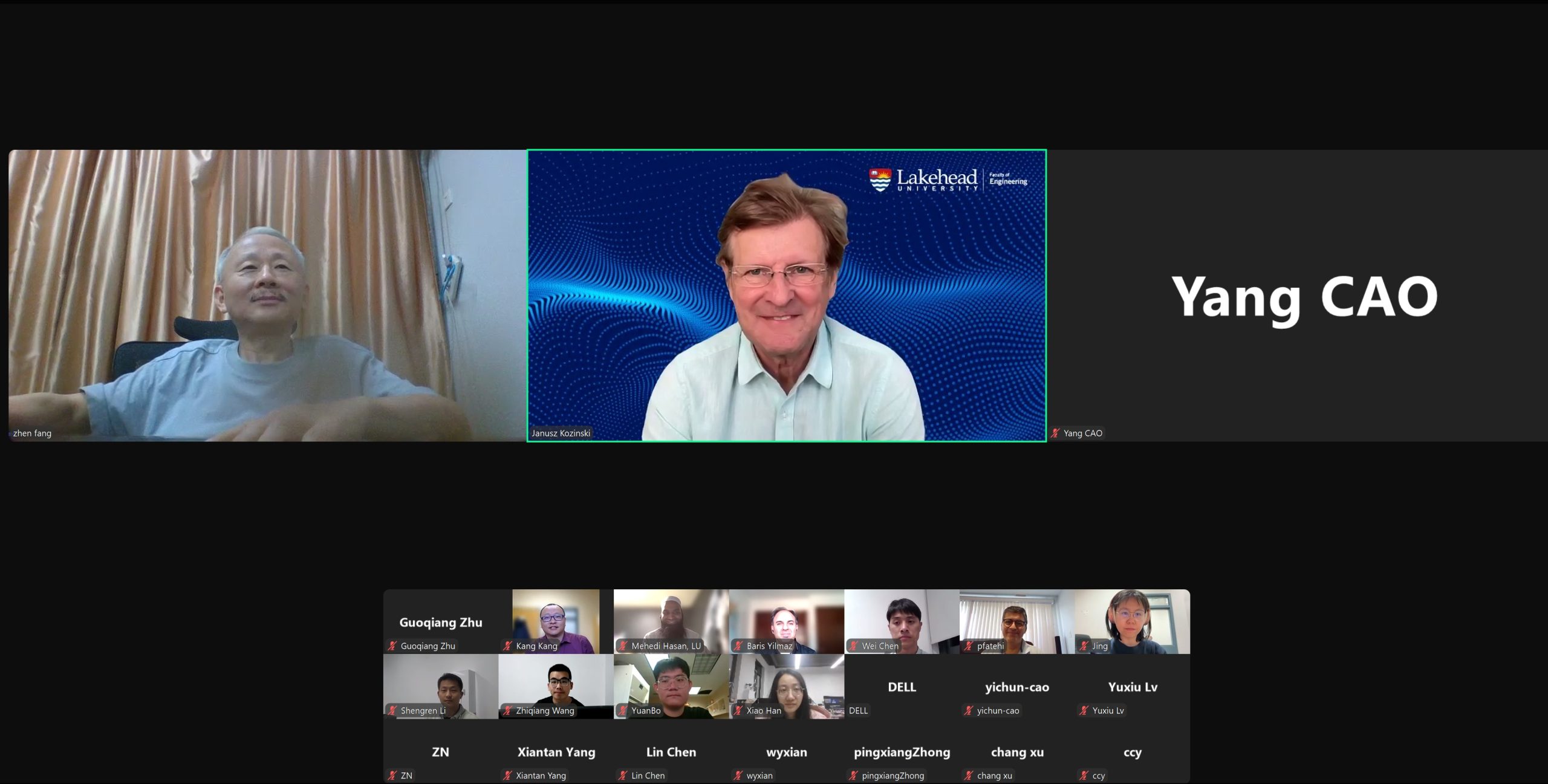

In the afternoon, May 16, 2025, graduate thesis defence for PhD student Miss Jing-jing Guo, and Master students Miss Yu-rou Wang, Miss Hong-li Ma, Miss Wan-ying Qiu (supervised by Prof. Zhen Fang), and Mr. Guo-qiang Zhu (supervised by Dr. Lujiang Xu) of Biomass Group at Nanjing Agricultural University (NJAU), was held at room B444, No.12 Building, Binjiang Campus, NJAU. Prof. Mao-hua Xiao from NJAU chaired the defence committee, and other four experts (Profs. Wei Zhuang and Jun Zhou from Nanjing Tech University), Profs. Wei-min Ding and Chun-xia He from NJAU) were invited as the members of the committee The defense secretary is Dr. Yang Cao.

The five students presented their theses before the Panel after past external review and courses and replied questions raised by all the members.

Miss Guo presented her PhD dissertation work entitled “A Study on One-step Production of Biodiesel from High Acid Value Waste Oil with Immobilized Lipase”.

Miss Wang presented her master thesis work entitled “A Study on Agroforestry Biomass Simultaneous KOH Activation and Ammoniation during Pyrolysis for Porous N-doped Biochar”.

Miss Ma presented her master thesis work entitled “A Study on Fast Pyrolysis of Bagasse Cellulose and Saccharification for Producing Ethanol via Fermentation”.

Miss Qiu presented her master thesis work entitled “A Study on Ethanol Production by Candida shehatae through Simultaneous Saccharification and Fermentation of Straw with High Solid Loading”.

Mr. Zhu presented his master thesis work entitled “Catalytic Pyrolysis of Waste Cooking Oils Deoxygenation for Producing Hydrocarbon-Rich Fuel and Life Cycle Assessment”.

All students published first-authored papers in prestigious Journals, i.e., 3 from Miss Guo, 1 from Miss Wang, 2 from Miss Ma (1 in Chinese), 1 from Miss Qiu and 1 Mr. Zhu, respectively. Miss Guo and Mr. Zhu were awarded the title of 2025 Outstanding Graduates of NJAU.

After secret ballot, the panel agreed to confer Doctor of Philosophy in Engineering to Miss Jing-jing Guo, and MSc in Engineering degree to Miss Yu-rou Wang, Miss Wan-ying Qiu and Mr. Guo-qiang Zhu, Master of science degree to Miss Hong-li Ma, subjected to the approval by the Academic Degrees Committees of the college and university.

All students found decent jobs.

Miss JJ Guo accepted a faculty position at a University in Huángshí, Hubei.

Mr. GQ Zhu will continue his PhD student at City University of Hong Kong.

Heartful Congratulations to Misses Guo, Wang, Ma and Qiu as well as Mr. Zhu!

—————————————————————————————————————-

五位学生通过硕博答辩

2025年5月16日下午,南京农业大学生物能源组2021级博士研究生郭静静(女)、硕士研究生王雨柔(女)、马宏莉(女)和邱婉莹(女)(导师方真教授)以及硕士生祝国强(导师徐禄江副教授)毕业答辩会在南京农业大学滨江校区工学院12号楼B442举行。南京农业大学的肖茂华教授担任答辩评审委员会主席,南京工业大学的庄伟教授和周俊教授,南京农业大学的丁为民教授和何春霞教授共五位专家担任答辩评审委员,答辩秘书为曹阳副教授。

答辩会上,郭静静、王雨柔、马宏莉、邱婉莹和祝国强五位同学依次对其在校期间的学术论文进行汇报,同时答辩委员会主席和各位评委提出了相关问题。根据五位同学的问题回答以及学位论文的外审意见,评委会经过评审决议,一致认为郭静静、王雨柔、马宏莉、邱婉莹和祝国强五位同学顺利完成了毕业所需要的研究和学习要求。

郭静静同学在毕业论文《固定化脂肪酶催化高酸值废油一步法制备生物柴油的研究》中探究了利用脂肪酶一步法转化高酸值美洲大蠊油制备生物柴油的可行性,解析了脂肪酶同时催化酯化和酯交换反应的作用机制。通过水热/热解制备了磁性生物炭,利用吸附-共价负载脂肪酶,实现了液相中脂肪酶的磁性分离和循环利用。进一步利用低共熔溶剂法实现了生物柴油的生产和纯化。王雨柔同学在毕业论文《农林生物质同步KOH活化和氨化热解制备多孔掺氮炭的研究》中研究了不同工况下同步活化氨化热解过程中KOH和NH3交互作用机理,分析了纤维素和木质素同步活化氨化热解机理,并探究了原料特性、炭材料物化性能和应用特性之间的关联,为生物质制备多孔掺氮炭提供了参考。马宏莉同学在毕业论文《快速热解蔗渣纤维素并水解糖化发酵产乙醇的研究》中以蔗渣为研究对象,通过碱性过氧化氢预处理,以实现纤维素的富集,并通过改变纤维素晶体结构,以提高热解糖化率。进一步合成可回收固体酸,将左旋葡聚糖水解为可发酵糖,用于纤维素乙醇的绿色发酵生产。邱婉莹同学在毕业论文《休哈塔假丝酵母利用高固含量秸秆同步糖化发酵生产乙醇的研究》中选择具有发酵葡萄糖和木糖能力的休哈塔假丝酵母(Candida Shehatae CICC 1967),系统探究其在不同培养基条件下的发酵性能。选取玉米秸秆和小麦秸秆作为原料,经酸碱预处理后,利用休哈塔假丝酵母进行延迟补料式同步糖化发酵,实现微生物高效发酵秸秆生产高浓度乙醇的目标。祝国强同学在毕业论文《催化热解废弃油脂脱氧制备富烃燃料及生命周期评价》中研究了废弃油脂热解聚脱氧定向制备富烃燃料并对工艺进行了全生命周期评价,通过不锈钢催化改性成功制备了富烃液体燃料,还通过生物炭催化热解耦合气相沉积工艺成功联产了碳纳米管和富烃燃料,为交通运输业碳减排提供了参考。

郭静静同学以第一作者身份共发表学术论文3篇,王雨柔同学以第一作者身份共发表学术论文1篇,马宏莉同学以第一作者身份共发表学术论文2篇(其中1篇为中文),邱婉莹以第一作者身份共发表学术论文1篇,祝国强同学以第一作者身份共发表学术论文1篇,郭静静和祝国强同学获得了2025年南京农业大学优秀毕业生称号。

经评委会无记名投票表决,一致同意郭静静同学通过博士学位论文答辩,建议授予工学博士学位;王雨柔同学通过硕士学位论文答辩,建议授予工学硕士学位;马宏莉同学通过硕士学位论文答辩,建议授予理学硕士学位;邱婉莹同学通过硕士学位论文答辩,建议授予工学硕士学位;祝国强同学通过硕士学位论文答辩,建议授予工学硕士学位。

热情祝贺五位同学!

Publications发表的论文:

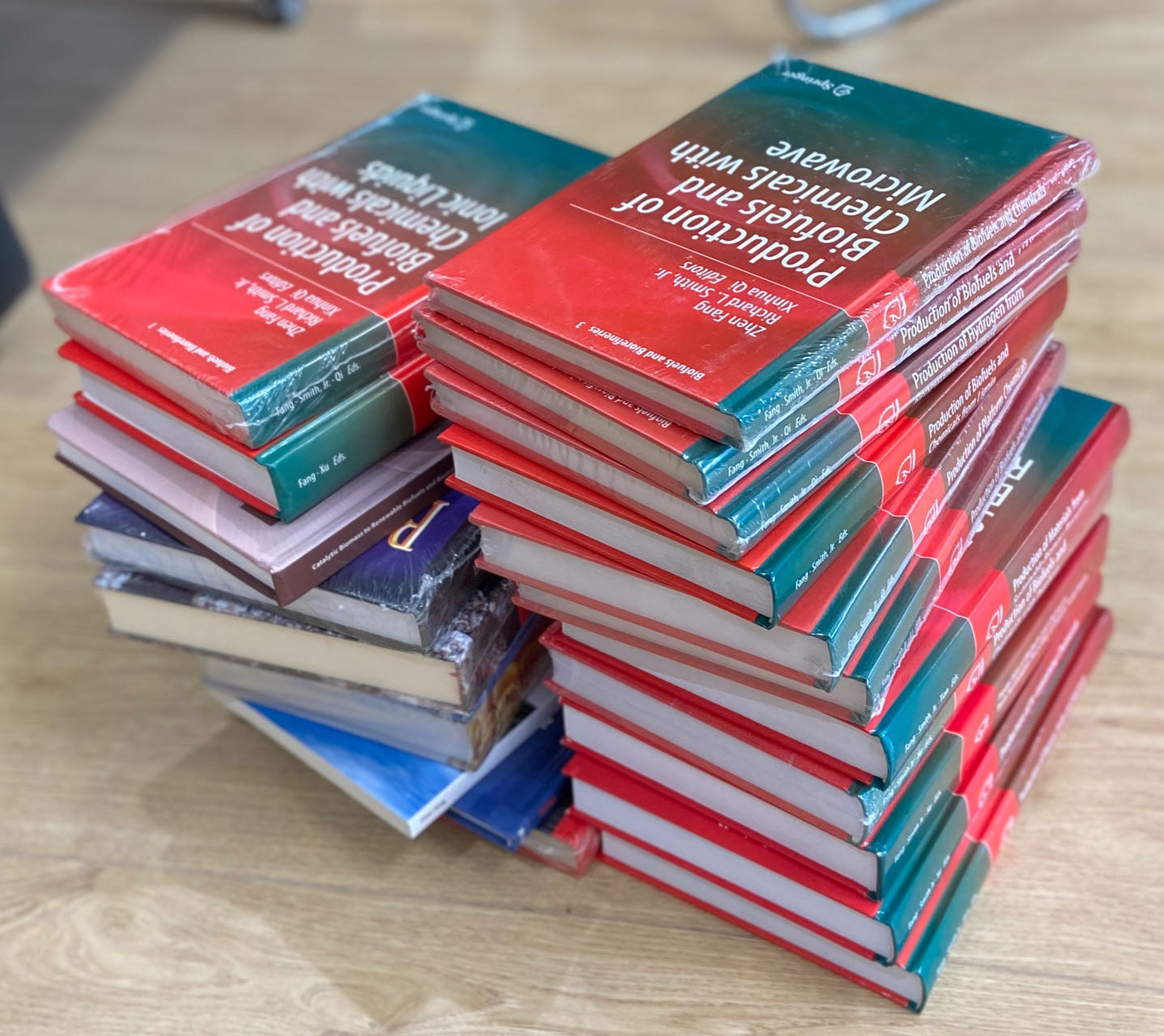

[1] J-J Guo, S Gao, J Yang, H Zhang, Y-T Wang, W-N Ding, Zhen Fang*. Biodiesel production via simultaneous esterification and transesterification of Periplaneta americana oil with liquid lipase Eversa® transform 2.0. Renewable Energy, 2024, 229, 120756. https://doi.org/ 10.1016/j.renene.2024.120756

[2] J-J Guo, Y-T Wang, Zhen Fang*. Covalent immobilization of lipase on magnetic biochar for one-pot production of biodiesel from high acid value oil. Bioresource Technology, 2024, 394, 130237. https://doi.org/10.1016/j.biortech.2023.130237

[3] J-J Guo, L Wang, Y-T Wang, W-N Ding, W-W Liu, Zhen Fang*. Lipases immobilized on hydrophobic biochar for one-step production of biodiesel in deep eutectic solvent. Fuel, 2025, 381, 133497. https://doi.org/10.1016/j.fuel.2024.133497

[4] YR Wang, WJ Guo, W Chen, GX Xu, GQ Zhu, GL Xie, LJ Xu, CY Dong, S Gao, YQ Chen, HP Yang, HP Chen, Z Fang. Co-production of porous N-doped biochar and hydrogen-rich gas production from simultaneous pyrolysis-activation-nitrogen doping of biomass: Synergistic mechanism of KOH and NH3. Renewable Energy 2024, 229, 120777. https://doi.org/10.1016/j.renene.2024.120777

[5] HL Ma, FX Xu, YC Zhang, MJ Huang, MF Li, GH Wang, MX Huang, Zhen Fang*, LQ Jiang*. Non-unified effects of cellulose allomorphs on fast pyrolysis and enzymatic hydrolysis, Industrial Crops and Products, 2025, 230, 121153. https://doi.org/10.1016/j.indcrop.2025.121153

[6] WY Qiu, CY Dong*, J-J Guo, B Xia, LJ Xu, Zhen Fang*. Enhancing xylose fermentation to maximize net energy gain of lime-pretreated wheatstraw by delayed fed-batch simultaneous saccharification and fermentation. Biomass Conversion and Biorefinery, 2025, 15, 107865. https://doi.org/10.1016/j.biombioe.2025.107865

[7] GQ Zhu, MX Zhu, EZ Wang, CX Gong, YR Wang, WJ Guo, GL Xie, W Chen, C He, LJ Xu*, H Li, Y Zhang, Z Fang. Natural biochar catalyst: Realizing the co-valorization of waste cooking oil into high-quality biofuel and carbon nanotube precursor via catalytic pyrolysis process. Chemical Engineering Journal, 2024, 486, 150195. https://doi.org/10.1016/j.cej.2024.150195