Cellulase immobilized on mesoporous biochar synthesized by ionothermal carbonization of cellulose

Recently, Mr. Chang-hui Zhu (a PhD student from Guangzhou Institute of Energy Conversion, Chinese Academy of Sciences) supervised by Prof. Zhen FANG synthesized biochar via ionothermal carbonization and pyrolysis, and it was subsequent used to adsorb free cellulase physically for enzymatic hydrolysis.

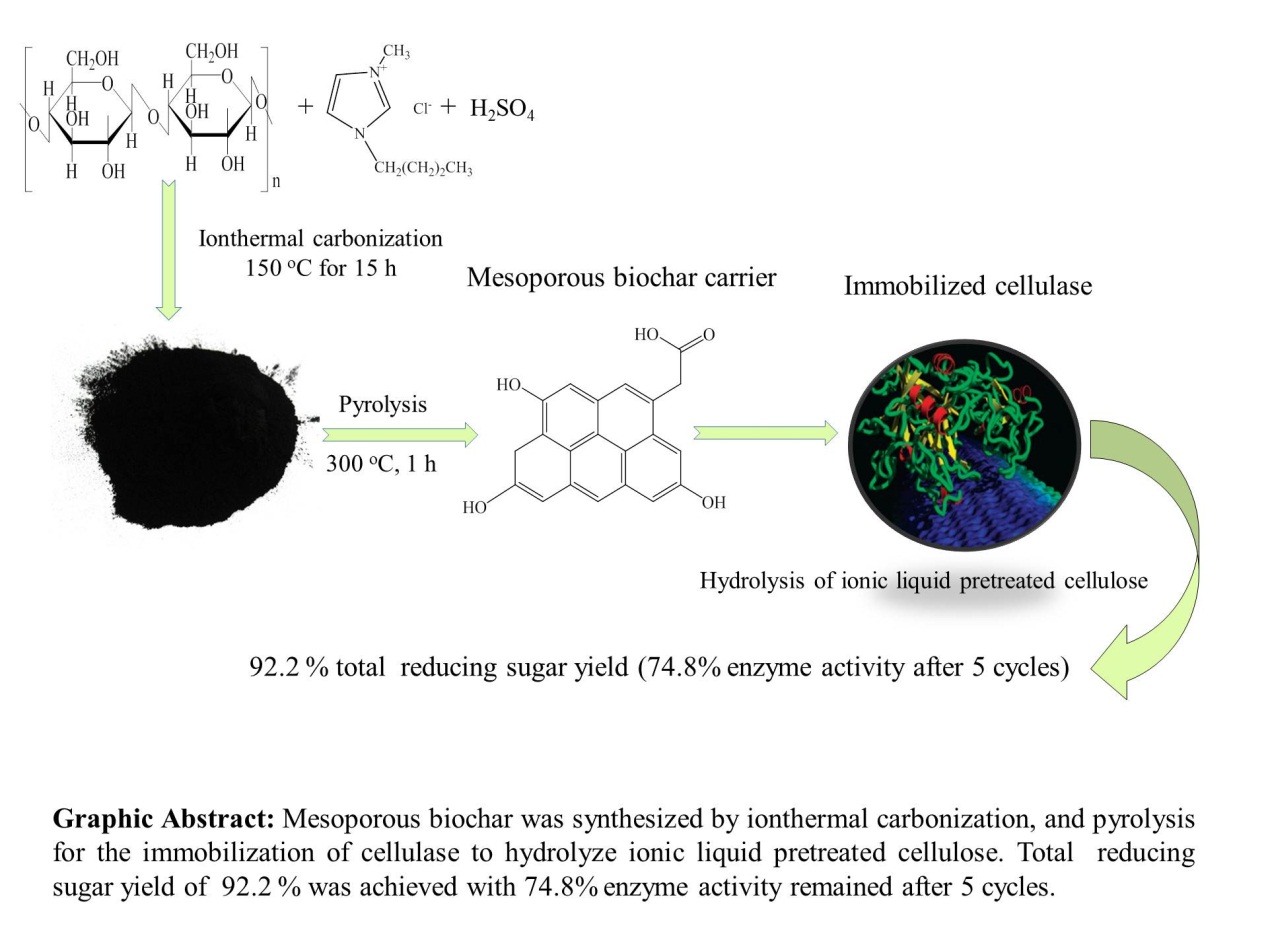

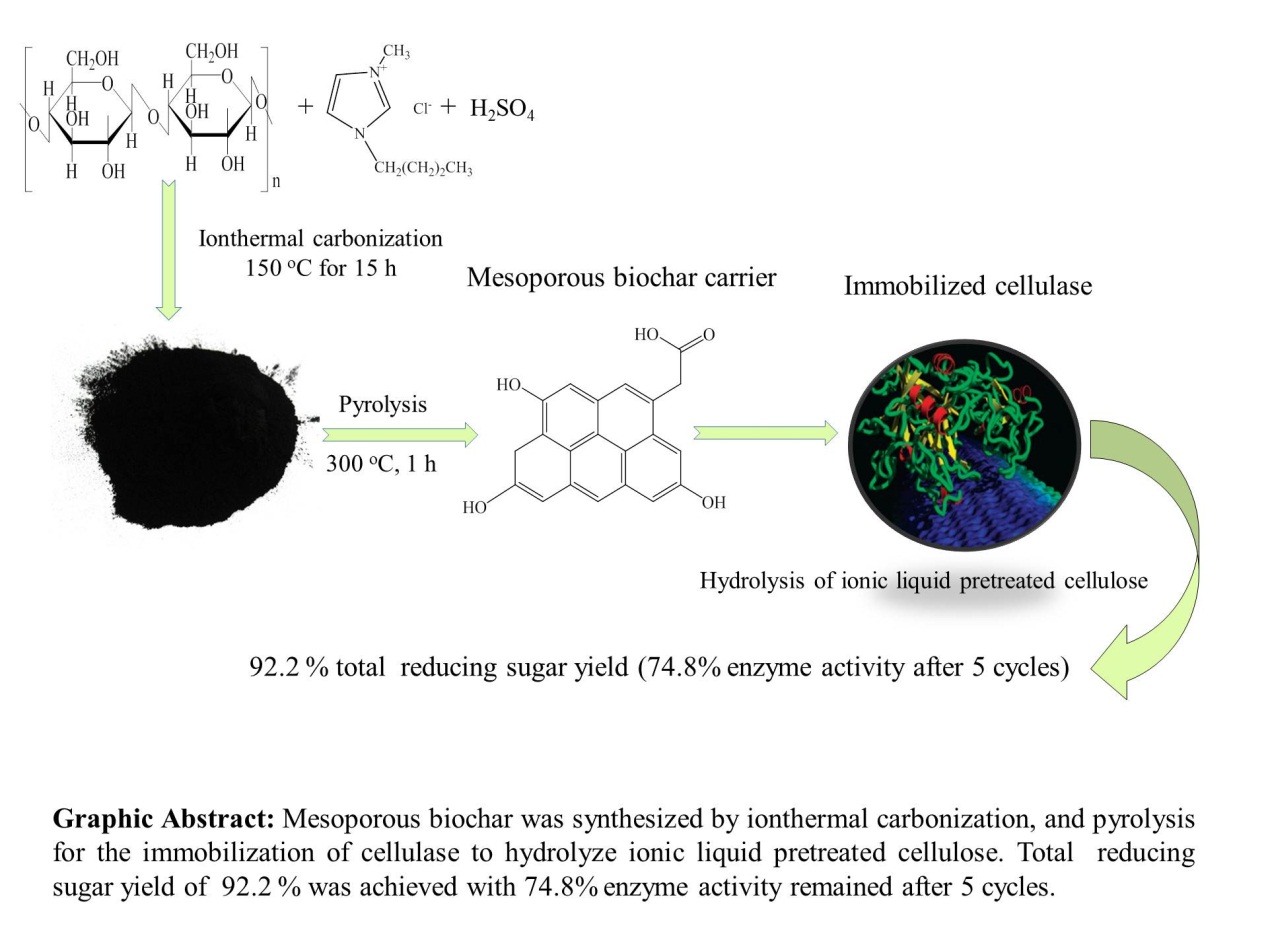

In order to recover free cellulase, a mesoporous biochar was synthesized from cellulose by ionic thermal and pyrolysis methods for the adsorption of free cellulase. Kinetics analysis showed that the affinity of the immobilized cellulase to carboxymethyl cellulose was better than that of free cellulase. The immobilized cellulase at different pH and temperatures was more stable than those of free cellulase. It was used to hydrolyze pretreated cellulose with [Bmim]Cl with total reducing sugar yield of 99.9%. The immobilized cellulase activity can still retain 74.8% after 5 cycles. Lastly, the immobilized cellulase can improve sugar production from the pretreated corncob for potential practical applications.

Results were published in Cellulose: Chang-hui Zhu, Zhen Fang*, Tong-chao Su, and Qi-ying Liu, Cellulase Immobilized on Mesoporous Biochar Synthesized by Ionthermal Carbonization of Cellulose, Cellulose, 25(4), 2473-2485 (2018).

Mesoporous biochar was synthesized by ionothermal carbonization, and pyrolysis for the immobilization of cellulase to hydrolyze ionic liquid pretreated cellulose and corncob. During pretreated cellulose hydrolysis, total reducing sugar yield of 92.2 % was achieved with 74.8% enzyme activity remained after 5 cycles.(通过离子热和热解方法合成了介孔生物炭,该生物炭用于固定纤维素酶,固定化纤维素酶用于水解离子液体预处理的纤维素以及玉米芯。其中在预处理纤维素水解,总还原糖产率可达92.2%,固定化酶循环使用5次后,活性仍保留74.8%)。

最近,朱长辉同学(中国科学院广州能源研究所博士研究生)在方老师的指导下,通过离子热和热解法由纤维素合成生物炭以及后续物理吸附制备固定化纤维素酶,并将其应用于离子液体预处理纤维素/生物质的水解。

为了回收游离纤维素酶,通过离子热和热解两步法由纤维素合成一种介孔生物炭以用于吸附游离纤维素酶。动力学分析表明,固定化纤维素酶对羧甲基纤维素的亲和力优于游离纤维素酶。 不同pH和温度下的固定化纤维素酶比游离纤维素酶更稳定。该固定化酶具有较好的催化预处理纤维素水解的能力,总还原糖产率可达92.2%,固定化酶循环使用5次后,活性仍保留74.8%。最后,该固定化酶结合离子液体预处理技术,对水解生物质纤维素表现出一定的应用前景。

结果发表在Cellulose: Chang-hui Zhu, Zhen Fang*, Tong-chao Su, and Qi-ying Liu, Cellulase Immobilized on Mesoporous Biochar Synthesized by Ionthermal Carbonization of Cellulose, Cellulose 25(4), 2473-2485 (2018).