超顺磁酸碱双功能纳米ZrFeOx催化剂的合成及用以生产生物燃料

星期六, 30 1 月, 2016超顺磁酸碱双功能纳米ZrFeOx催化剂的合成及用以生产生物燃料

酸碱双功能纳米颗粒广泛用来合成生物燃料和高附加值的化学品。特别是磁性纳米金属氧化物,活性高可一锅法生产生物燃料,易于回收和重复利用。

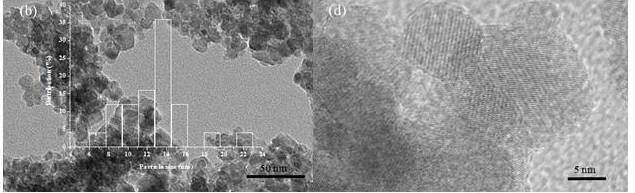

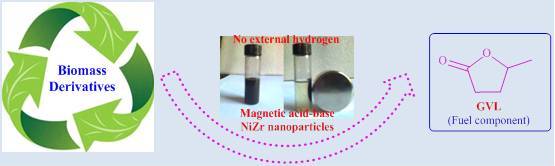

生物能源组与贵州大学联合培养的博士生李虎在导师杨松教授和方真研究员的指导下,通过溶剂热处理和水解缩合的两步法合成酸碱双功能的超顺磁性纳米颗粒。合成的ZrFeOx纳米颗粒大约为12 nm, 中心为Fe3O4纳米颗粒(作为磁核),其外面覆盖了一层0.65 nm厚的ZrO2。ZrFeOx纳米颗粒具有分布良好的酸碱含量(0.39 vs. 0.28 mmol/g),适度的表面积(181 m2/g),孔径(9.8 nm)和较强的磁性(35.4 Am2 kg−1)。ZrFeOx纳米颗粒在乙醇中,进一步用来催化乙酰丙酸乙酯转换为γ戊内酯(GVL): 在230 ºC,反应3小时,GVL产率可高达87.2%。该纳米催化剂与固体酸HY2.6组合,可将糖直接转化为GVL,得到适中产率(约45%)。此外,磁性ZrFeOx纳米颗粒可很方便地由磁铁回收,可进行至少六次的重复利用。

祥情可见:

H Li, Zhen Fang*, S Yang, Direct Conversion of Sugars and Ethyl Levulinate into γ-Valerolactone with Superparamagnetic Acid-Base Bifunctional ZrFeOx Nanocatalysts, ACS Sustainable Chemistry & Engineering, 4(1), 236-246 (2016).

Synthesis of Superparamagnetic Acid−Base Bifunctional ZrFeOx Nanocatalyst for Biomass Conversion

Acid−base bifunctional nanocatalysts can directly on-pot produce biofuels and chemical from biomass. Particularly, some magnetic metal oxides that are active and recyclable.

Mr. Hu Li, a PhD student, co-supervised by Prof. Song Yang (Guizhou University) and Prof. Zhen FANG (Biomass Group, Xishuangbanna Tropical Botanical Garden, CAS) successfully synthesized bifunctional ZrFeOx nanocatalyst for biomass conversions.

In their work, acid-base bifunctional superparamagnetic FeZrOx nanoparticles were synthesized via a two-step process of solvothermal treatment and hydrolysis-condensation, and were further employed to catalyze the conversion of ethyl levulinate (EL) to γ-valerolactone (GVL) using ethanol as both H-donor and solvent. ZrFeO(1:3)-300 nanoparticles (12.7 nm) with Fe3O4 core covered by ZrO2 layer (0.65 nm thickness) having well- distributed acid-base sites (0.39 vs. 0.28 mmol/g), moderate surface area (181 m2/g), pore size (9.8 nm) and strong magnetism (35.4 Am2 kg−1) exhibited superior catalytic performance, giving a high GVL yield of 87.2% at 230 ºC in 3 h. The combination of the nanoparticles with solid acid HY2.6 promoted the direct transformation of sugars to produce GVL in moderate yield (around 45%). Moreover, the nanocatalyst was easily recovered by a magnet for six cycles with an average GVL yield of 83.9% from EL.

The study was published:

H Li, Zhen Fang*, S Yang, Direct Conversion of Sugars and Ethyl Levulinate into γ-Valerolactone with Superparamagnetic Acid-Base Bifunctional ZrFeOx Nanocatalysts, ACS Sustainable Chemistry & Engineering, 4(1), 236-246 (2016).

TEM images of ZrFeOx nanocatalyst