腾冲科学家论坛Lectures in Tengchong No.1 Middle School

30 12 月, 2023Lectures in Tengchong No.1 Middle School

On December 3, 2023, one of the activities of “Tengchong Scientists Forum series – Academician Science Popularization into Campus Activity” was held at Tengchong No.1 Middle School. The theme of the activity is “Love Science and Advocate Science”, which stimulates the interest of young people in exploring science through forms such as science popularization lectures, science experiment shows, and science popularization book exhibitions.

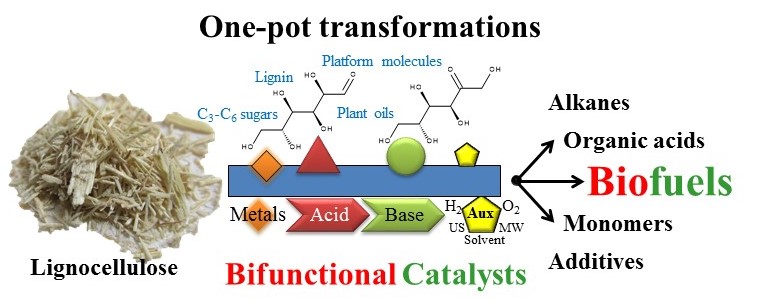

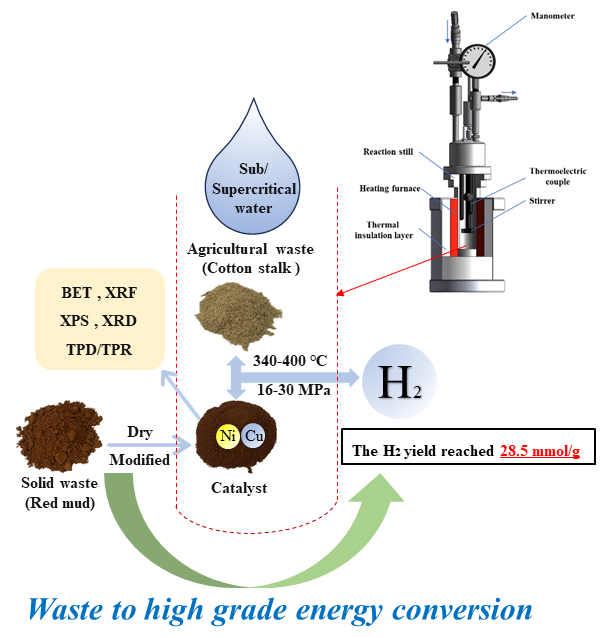

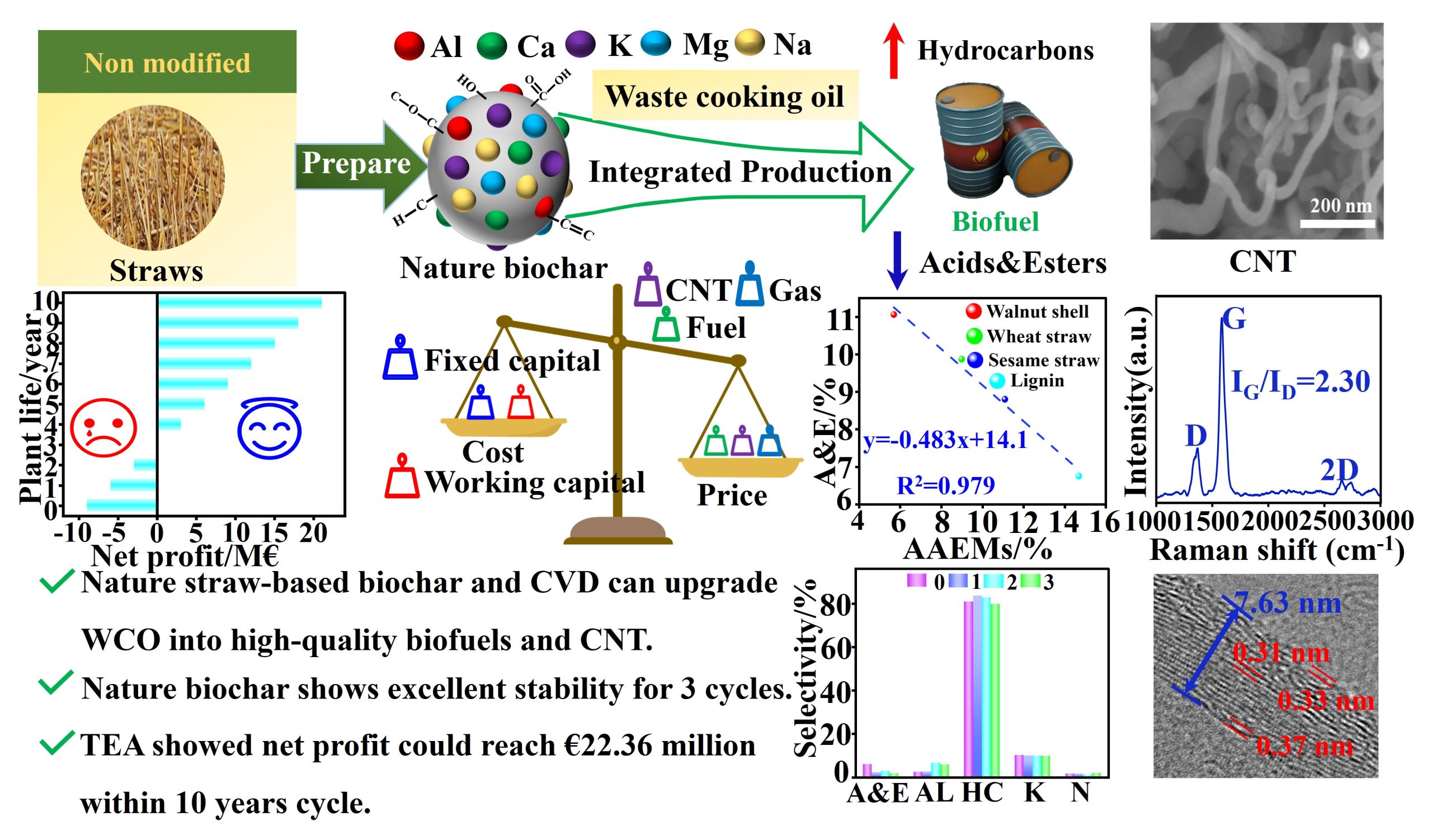

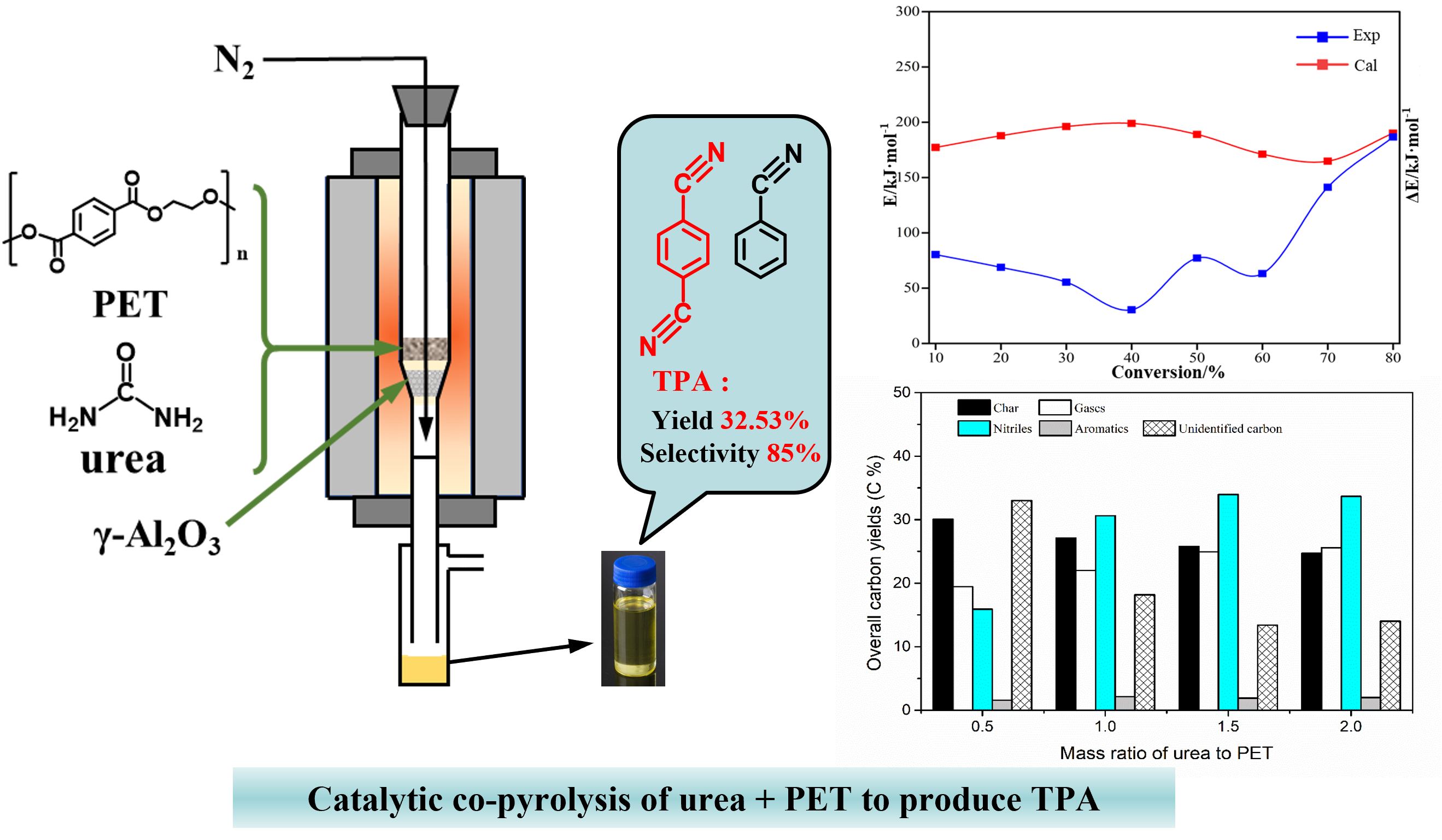

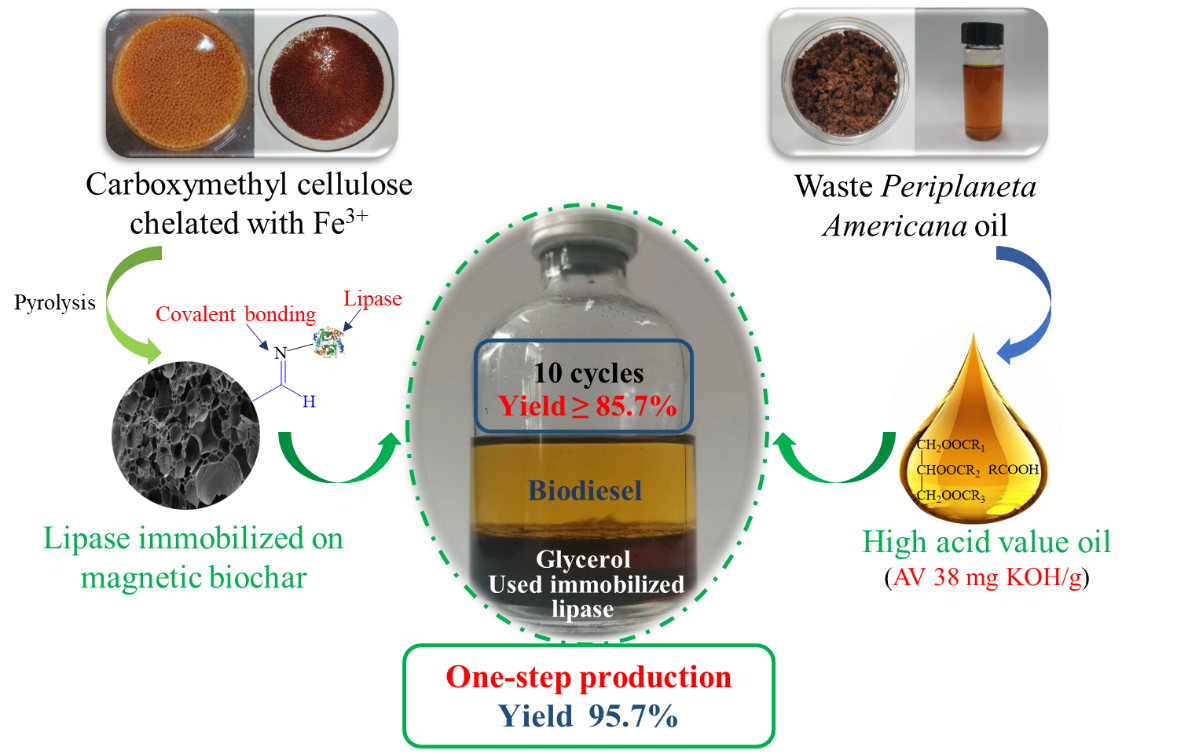

On the day of the event, Prof. Keqin Zhang (Academician of CAS), Dr. Zhaoyun Zhu (Academician of CAE), Prof. Caucher Birkar from Tsinghua University (2018 Winner of the Fields Medal), and Prof. Zhen Fang (Fellow of the Canadian Academy of Engineering), gave lectures in their respective fields. Prof. Zhen Fang gave a talk on “Biorefining agricultural and forestry biomass as fuel and high value-added products”. The 14th batch of Yunnan Province Science Popularization Base awarding ceremony was held on-site; The scientific experiment exhibition – Fun Science Gallium – was welcomed by teachers and students on site.

Prof. Caucher Birkar and Prof. Zhen Fang

Prof. Caucher Birkar and Prof. Zhen Fang

方老师参加“腾冲科学家论坛系列活动之一——院士科普进校园活动”

12月3日,2023腾冲科学家论坛系列活动之一——院士科普进校园活动在腾冲一中举行。活动以“热爱科学 崇尚科学”为主题,通过科普讲座、科学实验秀、科普图书展等形式,激发青少年探索科学的兴趣。

活动当天,中国科学院院士张克勤、中国工程院院士朱兆云、清华大学丘成桐数学科学中心教授考切尔•比尔卡尔(2018年菲尔兹奖获得者-数学诺奖)、加拿大工程院院士方真(南京农业大学教授)结合各自领域展开科普。现场举行了第十四批云南省科普基地授牌仪式;科学实验展演——趣味科学“镓”受到现场师生欢迎。

中国科学院院士张克勤以《真菌与线虫的战争》为题,从作物的杀手——根结线虫、线虫的天敌——捕食线虫真菌、真菌如何设置陷阱等六个方面,通俗易懂地讲解了真菌与线虫之间的战争。中国工程院院士朱兆云以《话说中药》为题,从历史上的中药、现代中药和云南中药三个部分,展示了中药作为中国科学文化的瑰宝所具有的无限魅力,详细介绍云南白药传承创新发展的历程。伊朗裔英籍数学家考切尔•比尔卡尔以《From Science to Happiness》为题,阐释了如何从科学中获得幸福,如何在解决问题、发现奥秘中收获喜悦,如何正确认识教育在科学研究发现中的重要作用。加拿大工程院院士方真以《生物精炼农林生物质为燃料和高附加值产物》为题,介绍了生物质资源、生物炼制、生物质的几种水解方式,分享如何通过化学、生物的方法将糖转化为高附加产物以及合成生物柴油,展现生物技术在实现经济可持续发展和环保方面的积极作用。

省科技厅党组书记、厅长王学勤表示,院士科普进校园活动搭建了院士专家与青年学生的交流平台,不仅是教育“双减”中做好科学教育加法的具体举措,更是践行习近平总书记关于科技创新和科学普及“一体两翼”理论,促进两翼齐飞的重要载体。以此次活动为契机,希望同学们心怀科学梦想、树立创新志向,爱科学、懂科学、学科学,传承科学家精神。

昆明日报全媒体记者:张怡

责编:莫开井