Welcome to Wood Refinery

Our inventions provide a simple and lowest-cost method to quickly dissolve and hydrolyze lignocellulosic biomass with great potential for a novel biorefinery.

Our vision is to develop the world’s best industrial-scale technology at competitive cost to produce ethanol, chemicals and industrial sugar from woody biomass by continuously fast hydrolysis in a flow reactor with water at supercritical conditions.

Our Technology:

- Synthesis and application of nano-catalysts, including catalyze jatropha oil for biodiesel, hydrothermal synthesis of lactic acid from glycerol and catalyze hydrolysis of lignocellulose to fermentable sugar production;

- Hydrothermal hydrolysis of cellulose, wood cellulose to fermentable sugars, organic acids, etc.;

- Amination of biomass-derived feedstocks to Nitrogen-containing compounds;

- Acidic ionic liquid catalysts applications (high-efficiency catalytic hydrolysis of wood cellulose);

- Precious metal catalysts synthesis and its catalytic preparation of hydrogen from biomass;

- Microbial fermentation of glycerol into lactic acid, propylene glycol and other chemicals, microbial fermentation of cellulose hydrolysis products into alcohols, ketones, organic acids and other secondary metabolites;

- Development and application of lignin;

- Magnetic solid catalyst for biodiesel production;

- One-step and low/room temperature synthesis of liquid biofuels from carbohydrates

Licensing or Collaboration

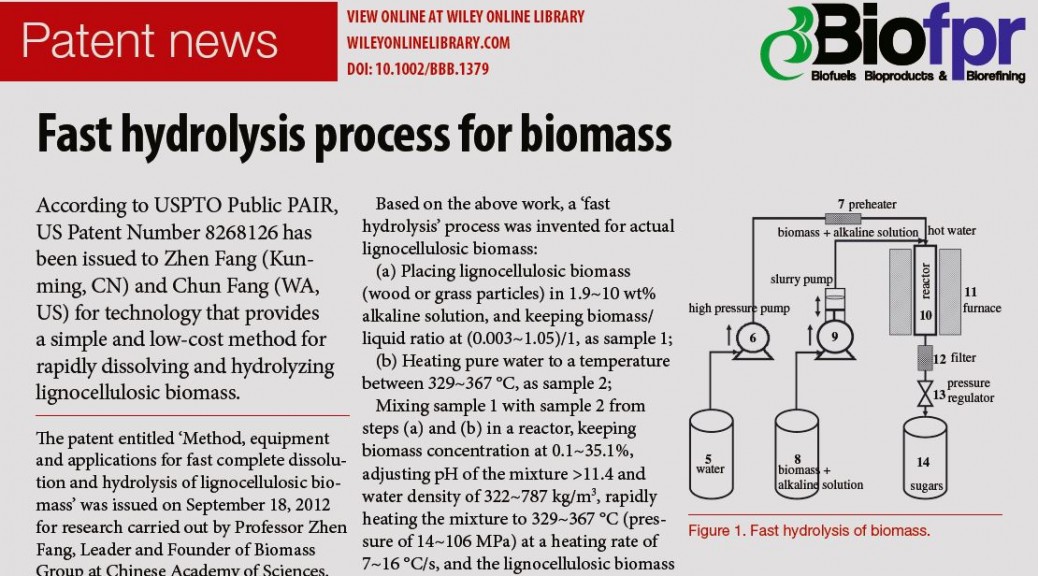

Briefly stated, Our inventions comprise method, equipment and applications for fast complete dissolution and hydrolysis of lignocellulosic biomass continuously. The unique features of our inventions are simple, complete, continuous and fast dissolution and hydrolysis of actual lignocellulosic biomass (wood or grass). The advantages of our inventions offer a simple, fast and low-cost way of applying it on a large commercial scale because of the unique features of the invention.

Professor Zhen Fang, co-founder of Wood Refi, have 23 years experiences in bioenergy research at top universities and institutes around the world.

- Fast hydrolysis of lignocelluloses: In his previous work, Professor Fang found for the first time that cellulose could be completely dissolved in water at temperature above 320 oC and became a ‘cellulose solution’, which made it possible to build up a continuous flow reactor for the rapid hydrolysis of cellulose. However, the separating of pure cellulose from actual biomass (e.g., wood) is complicated and costly. It is difficult for the solubilization and hydrolysis of pure cellulose to be commercialized. Thus, we invented a ‘fast hydrolysis’ process of actual lignocellulosic biomass (wood) by adding 0.8 wt% Na2CO3, actual wood without pretreatment can be completely dissolved upon fast-heating (7~16°C/s) to form a ‘wood solution’ at 329-367 oC at short reaction times (0.7-2 s). The ‘wood solution’ can be rapidly (ca. 15 s) hydrolyzed to sugars/sugar oligomers under homogeneous conditions. The patent is the latest development in Professor Fang’s 23-year effort in the study of biomass hydrolysis process, aimed at a simple, fast and low-cost method for a novel biorefinery. The ‘fast hydrolysis’ process will be the technological key to economic utilization of abundant lignocellulosic biomass as viable feedstocks for the production of industrial sugar, ethanol and chemicals. Our pioneering work opens the door, for the first time, to the possibility of developing industrial-scale technology at competitive cost for producing biofuels and value-added products from lignocellulosic biomass based on the ‘fast hydrolysis’ process in a flow reactor. (US patent#: 8268126, 2012; US patent#: 9115215, 2015; US patent#: 9243303, 2016; AIChE J, 54, 2751, 2008).

- Synthesis of amides from lignocelluloses: A protocol is developed that shows in situ formed N-formyl quasi-catalytic species afford highly selective synthesis of formamides or amines with controllable levels from a variety of aldehyde- and ketone-derived platform chemical substrates (that can be easily produced via our patented “fast hydrolysis” process from lignocelluloses and subsequent catalytic conversions) under solvent-free conditions. Up to 99% yields of mono-substituted formamides are obtained in 3 min. The C-N bond formation and N-formyl species are prevalent in the cascade reaction sequence. Kinetic and isotope labeling experiments explicitly demonstrate that the C-N bond is activated for subsequent hydrogenation, in which formic acid acts as acid catalyst, hydrogen donor and as N-formyl species source that stabilize amine intermediates elucidated with density functional theory. The protocol provides access to imides from aldehydes, ketones, carboxylic acids, and mixed-substrates, requires no special catalysts, solvents or techniques and provides new avenues for amination chemistry. (Patent: PCT/CN2019/098614, 2019; Nature Communications, 10, 699, 2019, Green Chem, https://doi.org/10.1039/C9GC03655E, 2020).

3. Magnetic solid catalyst for biodiesel production (一种用于生物柴油制备的碳基磁性固体催化剂合成方法) (Chinese patents: ZL201410764721.X, 2016; ZL201420785283.0, 2015; ZL201220038727.5, 2012; ZL201110334924.1, 2013).

A cheap and high active magnetic heterogeneous catalyst (Na2SiO3@Fe3O4/C) was prepared for the production of biodiesel from oils with high acid value (AV).

With the catalyst and assisted by US, soybean biodiesel yield reached > 90% in only 20 min (or at 318 K) and 97.9% under the optimal conditions. It was easily magnetically separated for 5 cycles with 94.9% recovery rate and biodiesel yield > 80% with both US and MS. The catalyst transesterified Jatropha oil with biodiesel yields of 94.7%, 93.2% and 83.5% at AV of 1.3, 4.8 and 7.3 (mg KOH/g) with US, and was cycled 5 times with yield > 70% at AV of 4.8 assisted by US and MS. High biodiesel yield (90.7%) was still achieved from high AV oil (4.8) at low US energy density (0.1 W/mL) and MS. The catalyst combined with US and MS can find practical application for direct production of biodiesel from oils with high AV.

Magnetically recyclable catalysts are synthesized to produce biodiesel in a compacted flow reactor without discharging liquid catalyst wastes. Short reaction time is achieved by using microwave and ultrasound.

(URL: https://woodrefinery.com/zhenfang/biodiesel-is-synthesized-successfully-in-a-pilot-continuous-compacted-flow-reactor-3-5-tday-designed-by-biomass-group/, Patented reactor license transferred to Shandong Yikang pharmaceutical co. LTD on Oct. 23, 2018).

———————————————————

4. One-step and low/room temperature synthesis of liquid biofuels from carbohydrates (Patents: PCT/CN2017/106729, CN 106861754 A).

Nanocatalysts were syntheisized to catalyze the high yield production of liquid biofuels (e.g., methyl levulinate, γ-valerolactone, 2,5-dimethylfuran, methylfuran) at low temperatures directly from carbohydrates (e.g., sugars, cellulose). It is found that 95% 2,5-dimethylfuran yield was obtained from fructose at 110 °C, 99% 2,5-dimethylfuran yield from 5-hydroxymethylfurfural and 97% 2-methylfuran yield from furfural were even achieved at room temperature (25 °C) when polymethylhydrosiloxane was used as H-donor. Therefore, liquid biofuels (e.g., 2,5-dimethylfuran) can be produced from sugars via the hydrolysis of lignocellulosic biomass that is easy for commercial applications in simple and inexpensive reactors.

Prof. Fang also synthesized nanocatalysts to catalyze the high yield production of liquid biofuels (e.g., methyl levulinate, γ-valerolactone, 2,5-dimethylfuran, methylfuran) at low temperatures directly from carbohydrates (e.g., sugars, cellulose). It is found that 95% 2,5-dimethylfuran yield was obtained from fructose at 110 °C, 99% 2,5-dimethylfuran yield from 5-hydroxymethylfurfural and 97% 2-methylfuran yield from furfural were even achieved at room temperature (25 °C) when polymethylhydrosiloxane was used as H-donor. Therefore, liquid biofuels (e.g., 2,5-dimethylfuran) can be produced from sugars via the hydrolysis of lignocellulosic biomass that is easy for commercial applications in simple and inexpensive reactors. (PCT/CN2017/106729, 2017; US patent, application #16499364, 2019)

We are seeking to sell or license the patent rights, or other forms of collaboration to commercialize it. If you are potentially interested in the U.S. patent #: 8268126. Please contact me anytime at Tel:646-543-5318, 86-871-5170024 or Tel: 86-25-58606657; E-mails: 483709907@qq.com; zhfa2020AThotmail.com