热解制备左旋葡聚糖High Yield Production of Levoglucosan via Catalytic Pyrolysis of Cellulose at Low Temperature

星期日, 24 4 月, 2022High Yield Production of Levoglucosan via Catalytic Pyrolysis of Cellulose at Low Temperature

Recently, Dr Li-Qun Jiang (Associate Prof., Institute of Biological and Medical Engineering, Guangdong Academy of Sciences), Prof. H Li (Guizhou University) and Prof. Zhen Fang published an article in Fuel about levoglucosan production from catalytic pyrolysis of cellulose with acid-base bifunctional magnetic Zn-Fe-C catalysts.

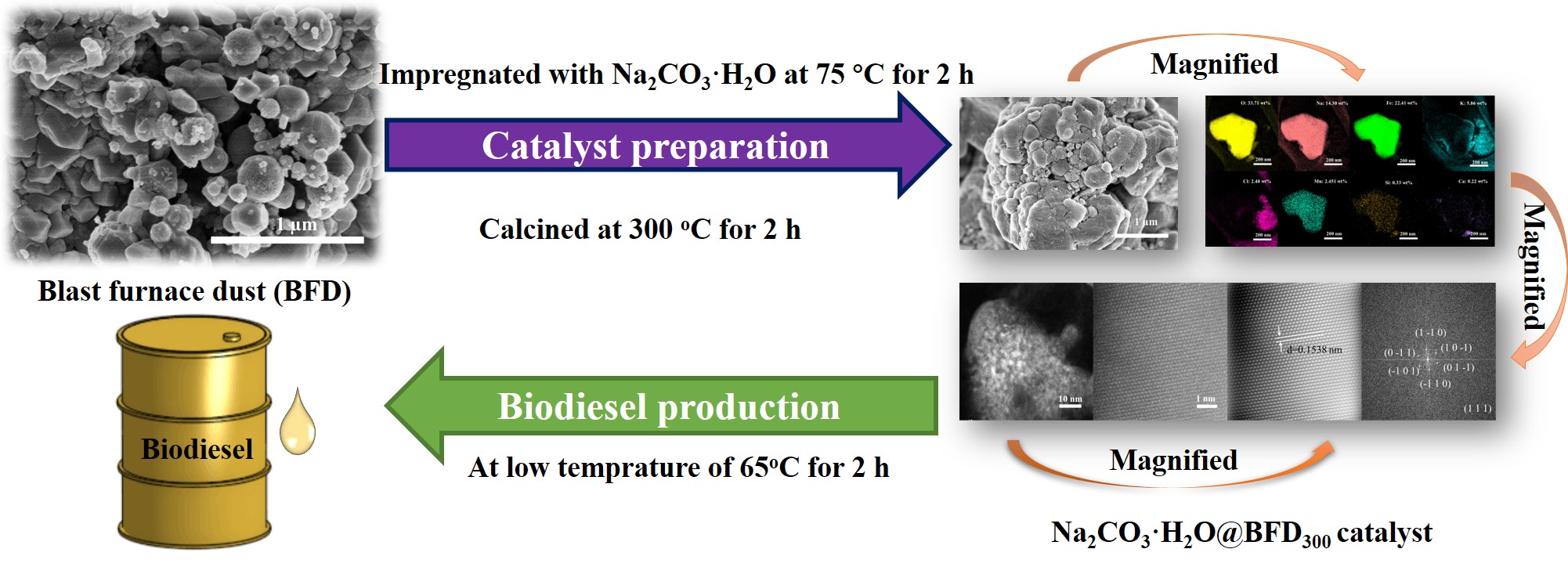

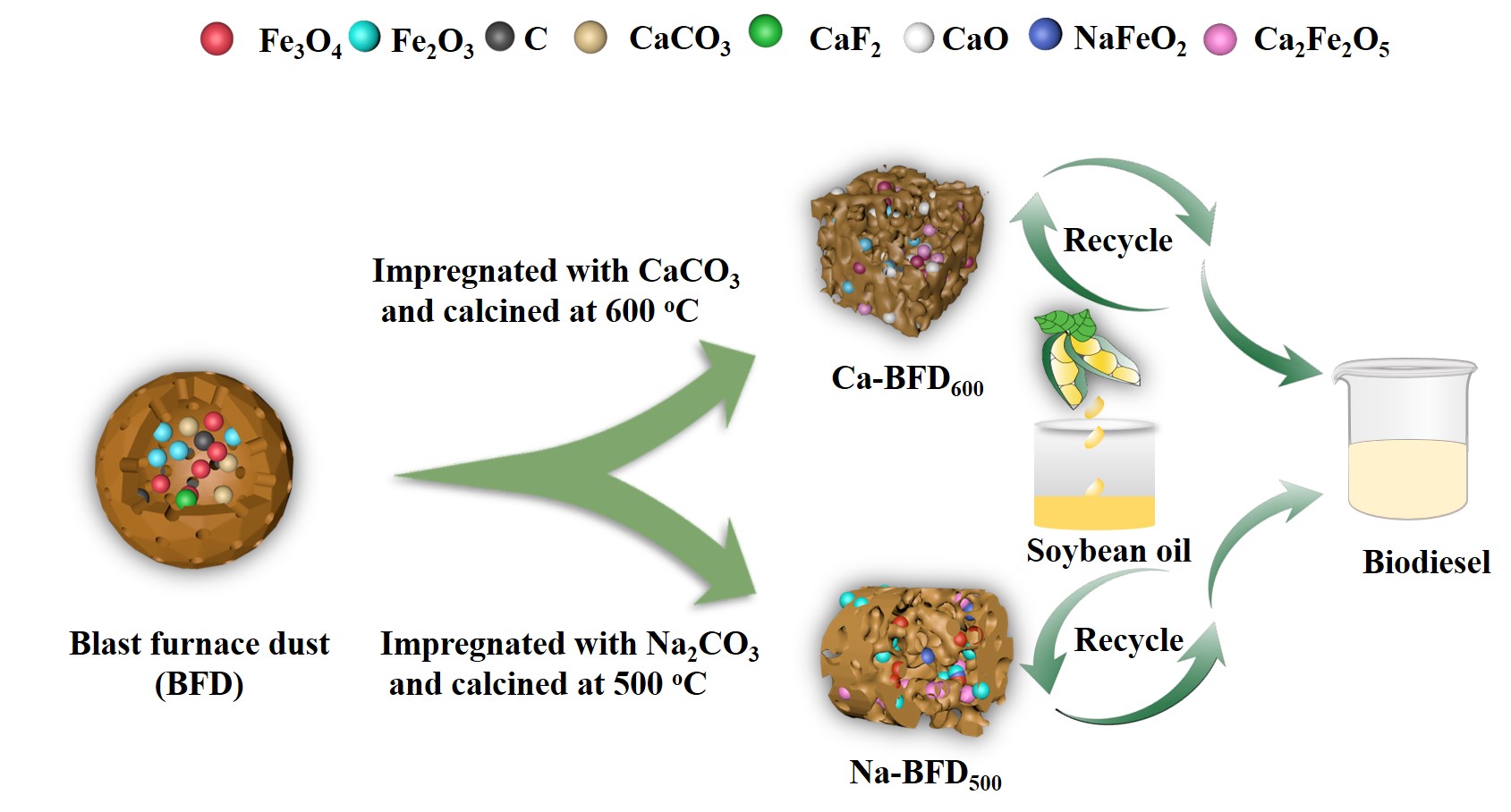

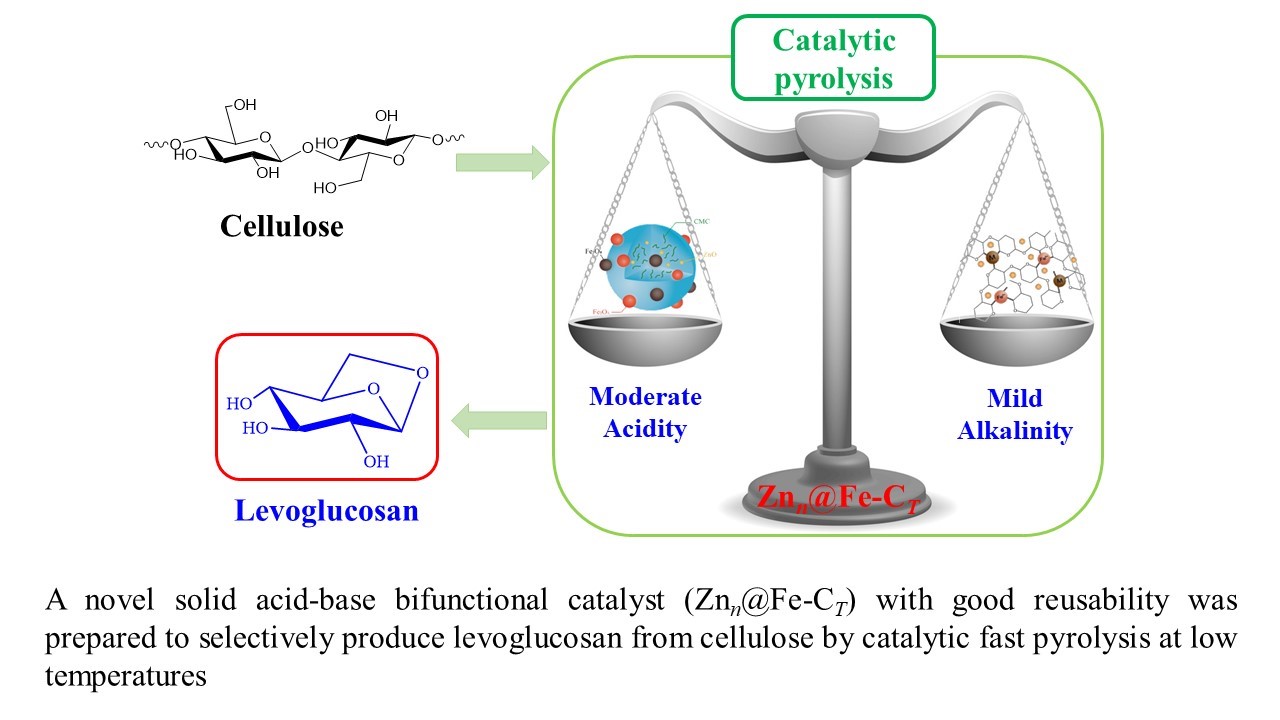

Catalytic pyrolysis of cellulose to levoglucosan in improved yields was achieved with acid-base bifunctional magnetic Zn-Fe-C catalysts. Among tested catalysts, Zn4@Fe-C500 could not only increase levoglucosan yield by 5.4 times compared with non-catalytic cellulose pyrolysis at 300 °C, but also help lower reaction temperature by 200 °C due to acid-base site synergistic effect. Furthermore, the levoglucosan yield (80.1 wt%) from catalytic cellulose pyrolysis at 300 °C was much higher than that commonly conducted at 500 °C without catalyst (60.1 wt%). Thermogravimetric and kinetic analysis disclosed levoglucosan formation mechanism. Importantly, Zn4@Fe-C500 catalyst was highly recyclable with little deactivation after 5 consecutive cycles. This study exhibited great potential for industrial levoglucosan production from cellulose at low temperatures. Related results were published in Fuel:

LQ Jiang, JC Luo, F Xu, L Qian, YT Wang, H Li*, Zhen Fang*, High Yield Production of Levoglucosan via Catalytic Pyrolysis of Cellulose at Low Temperature, Fuel, 323 (2022) 124369. https://doi.org/10.1016/j.fuel.2022.124369

.

Production of Levoglucosan via Catalytic Pyrolysis of Cellulose at Low Temperature with Znn@Fe-CT acid-base bifunctional magnetic catalyst磁性固体酸碱两性催化剂Znn@Fe-CT催化纤维素定向热解制备左旋葡聚糖

Production of Levoglucosan via Catalytic Pyrolysis of Cellulose at Low Temperature with Znn@Fe-CT acid-base bifunctional magnetic catalyst磁性固体酸碱两性催化剂Znn@Fe-CT催化纤维素定向热解制备左旋葡聚糖

磁性固体酸碱两性催化剂Znn@Fe-CT催化纤维素定向热解制备左旋葡聚糖

最近,蒋丽群博士(广东省科学院生物与医学工程研究所副教授), 李虎教授 (贵州大学)和方真教授在国际学术期刊Fuel(IF: 6.609,Q1)发表题为“High Yield Production of Levoglucosan via Catalytic Pyrolysis of Cellulose at Low Temperature”的研究性论文。该研究制备了磁性固体酸碱两性催化剂Znn@Fe-CT用于催化纤维素快速热解选择性制取左旋葡聚糖。相关研究表明,Zn4@Fe-C500催化热解纤维素不仅可以将热解糖化反应温度从500 ℃降低至300 ℃,并且300 ℃下催化热解纤维素得到左旋葡聚糖的产率(80.1 wt%)远高于500℃(60.1 wt%)。经过5次循环实验后Zn4@Fe-C500仍然可以提升左旋葡聚糖的产率。该研究为纤维素定向热解转化提供了新思路。详情可见:

LQ Jiang, JC Luo, F Xu, L Qian, YT Wang, H Li*, Zhen Fang*, High Yield Production of Levoglucosan via Catalytic Pyrolysis of Cellulose at Low Temperature, Fuel, 323 (2022) 124369. https://doi.org/10.1016/j.fuel.2022.124369

.