电炉粉制备生物柴油Production of biodiesel with electric furnace dust impregnated in Na2CO3 solution

电炉粉制备生物柴油Efficient production of biodiesel with electric furnace dust impregnated in Na2CO3 solution

Recently, Dr Yi-Tong Wang (Associate Prof., College of Metallurgy and Energy, North China University of Science and Technology) and Prof. Zhen Fang published an article in Journal of Cleaner Production about electric furnace dust impregnated with Na2CO3 solution for biodiesel production.

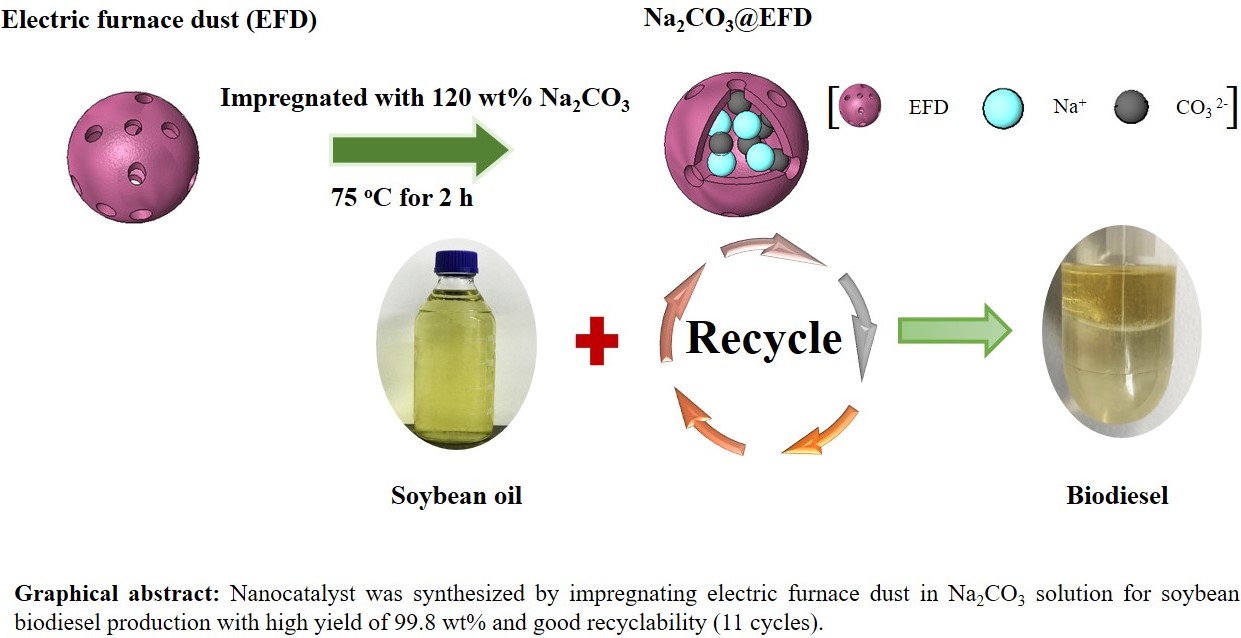

Solid catalyst (Na2CO3@EFD) was prepared by wet impregnation of electric furnace dust (EFD) in aqueous Na2CO3 solution. It had high basicity and acidity of 0.34 and 0.16 mmol/g for biodiesel production. High biodiesel yield of 99.8 wt% from soybean oil was obtained under the optimized reaction conditions (by Central Composite Design) of 71 oC in 111.36 min with 5.4 wt% catalyst and methanol/oil molar ratio of 11.8/1. After 11 cycles, biodiesel yield still maintained at 90.8 wt% with catalyst recovery rate > 90 wt% by magnetic separation of catalyst EFD powders (containing Fe3O4 with magnetism of 59.1 Am2/kg). Pure Na2CO3 particles presented poorer recyclability with lower biodiesel yield of 89.5 wt% even at the eighth cycle by centrifugal separation. Na2CO3@EFD catalyst had high activity and recyclability because: (i) EFD as support hosted nanoparticles of Na2CO3 (30.3 nm) as main base site for transesterification; (ii) porous EFD support provided acidic sites from metal oxides (e.g., ZnO and Al2O3) for esterification; (iii) EFD adsorbed active components into its micropores to maintain high recyclability; and (iv) EFD magnetism from magnetic Fe3O4 kept high efficient magnetic separation. Total metals in the blended biodiesel met the National Standard of China and heavy metals were lower than typical petrochemical diesel. The study provided a practical use of industrial solid waste for the green production of biodiesel.

Related results were accepted in Journal of Cleaner Production:

YT Wang, D Gao, YN Zeng*, JG Li*, AM Ji, TJ Liu, S Cai, WJ Cong, FP Wang, Q Yu, XM Wang, Zhen Fang*. Efficient Production of Biodiesel with Electric Furnace Dust Impregnated in Na2CO3 Solution. Journal of Cleaner Production, 330, 129772 (2022), https://doi.org/10.1016/j.jclepro.2021.129772.

Nanocatalyst was synthesized by impregnating electric furnace dust in Na2CO3 solution for soybean biodiesel production with high yield of 99.8 wt% and good recyclability (11 cycles). 电炉粉尘通过Na2CO3溶液浸渍后可用于催化豆油制备生物柴油,产率高达99.8 wt%,该催化剂具备良好的寿命,可循环使用11次。

王一同博士和方真教授在国际学术期刊Journal of Cleaner Production发表学术论文:

Na2CO3溶液浸渍电炉粉尘用于催化生物柴油高效生产

最近,王一同博士(女,华北理工大学冶金与能源学院副教授)和方真教授在国际学术期刊Journal of Cleaner Production(IF: 9.297,Q1)发表题为“Na2CO3溶液浸渍电炉粉尘用于催化生物柴油高效生产”的研究性论文。

利用Na2CO3水溶液湿法浸渍电炉粉尘后制备固体酸碱两性材料(Na2CO3@EFD),可用于催化生物柴油高效生产。多孔电炉粉尘作为载体将活性组分Na2CO3纳米粒子吸附到粉尘内部微孔中,同时为转酯化反应提供碱性活性位点,粉尘中的的酸性氧化物,如:ZnO和Al2O3,可为酯化反应提供所需的酸性活性位点,粉尘中的磁性铁氧化物可保证合成催化剂拥有高效的磁分离特性。在响应面优化的条件下,生物柴油的产率达到99.8 wt%,循环11次后仍可获得90.8 wt%的产率,催化剂的回收率> 90 wt%。该研究为生物柴油的绿色生产、工业固体废物绿色资源化提供新思路。详情可见:

YT Wang, D Gao, YN Zeng*, JG Li*, AM Ji, TJ Liu, S Cai, WJ Cong, FP Wang, Q Yu, XM Wang, Zhen Fang*. Efficient Production of Biodiesel with Electric Furnace Dust Impregnated in Na2CO3 Solution. Journal of Cleaner Production, 330, 129772 (2022), https://doi.org/10.1016/j.jclepro.2021.129772.