双功能Na-Fe-Ca催化剂生物柴油Production of biodiesel at low temperature using bifunctional Na-Fe-Ca nanocatalyst from blast furnace waste

Production of biodiesel at low temperature using bifunctional Na-Fe-Ca nanocatalyst from blast furnace waste

Recently, Dr Yi-Tong Wang (Associate Prof., College of Metallurgy and Energy, North China University of Science and Technology) and Prof. Zhen Fang published an article in Fuel about using highly active bifunctional Na-Fe-Ca nanocatalyst from blast furnace dust for biodiesel production.

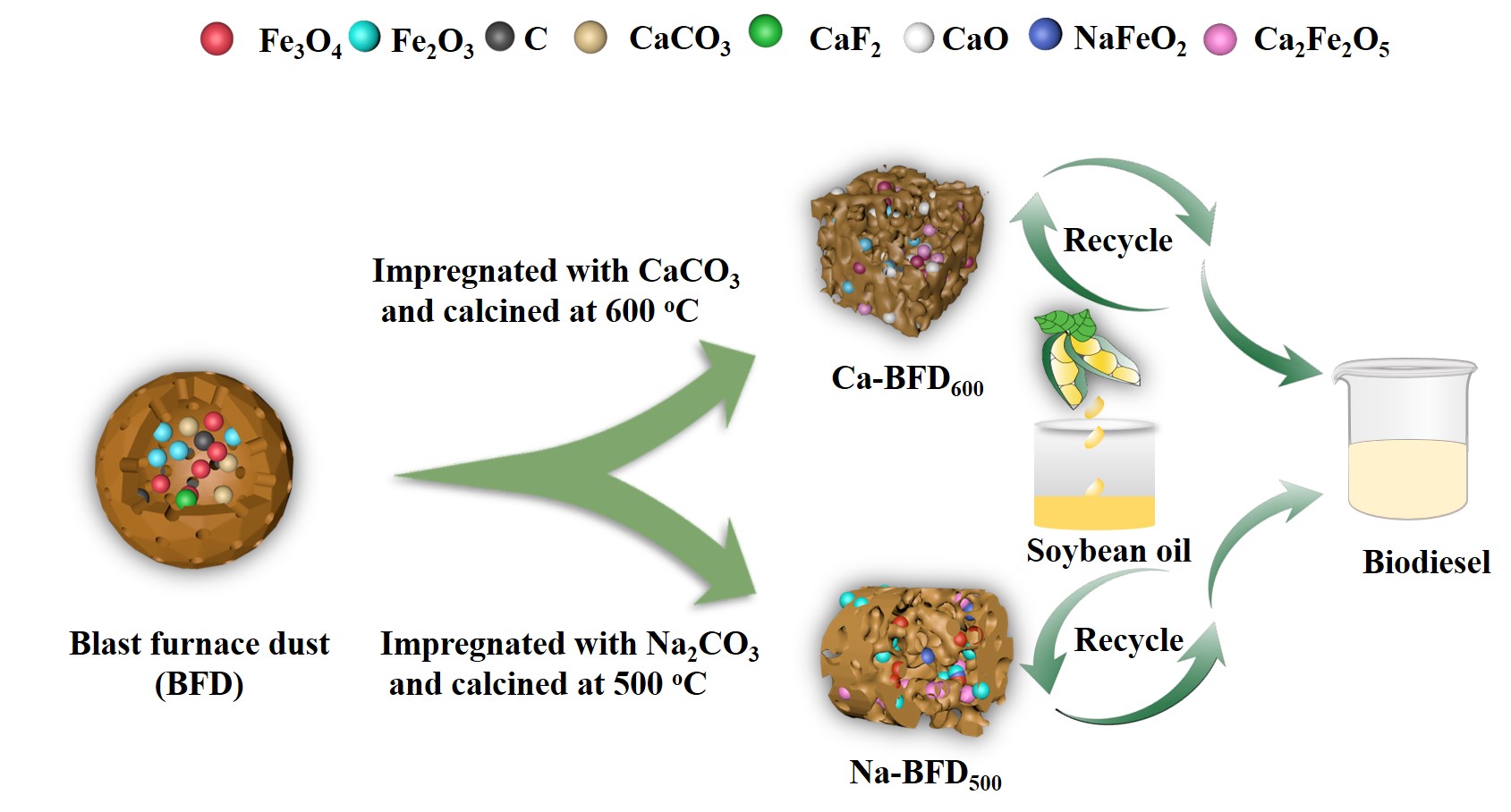

Nanocatalysts for biodiesel production were prepared via wet impregnation of blast furnace dust (BFD) in Na2CO3 (Na-BFD) and CaCO3 (Ca-BFD) suspension solutions and calcination at 500 and 600 oC, respectively. Biodiesel yields of 100.0 wt% (Na-BFD500) and 98.3 wt% (Ca-BFD600) were achieved at 65 oC. Synthesized catalysts showed outstanding activity and recyclability, due to the transition of CaCO3, Na2CO3 and Fe2O3 to nanocrystals of NaFeO2 (29.9 nm), Ca2Fe2O5 (10.5 nm), CaO (100.1 nm) and Ca2Fe2O5 (50.0 nm). Na-BFD500 achieved 95.8 wt% biodiesel yield with 16 cycles, whereas Ca-BFD600 reached 94.1 wt% biodiesel yield with 7 cycles via magnetic separation. BFD containing convertible magnetic and active components (Fe2O3 and CaCO3) was an ideal raw material to synthesize catalyst for biodiesel production with high catalytic efficiency and easy separation. The study provided a practical utilization of industrial solid waste for biodiesel production.

Related results were published in Fuel:

YT Wang, XM Wang, D Gao, FP Wang, YN Zeng, JG Li*, LQ Jiang, Q Yu, R Ji, LL Kang, YJ Wang, Zhen Fang*, Efficient Production of Biodiesel at Low Temperature Using Highly Active Bifunctional Na-Fe-Ca Nanocatalyst from Blast Furnace Waste, Fuel, 322, 124168, https://doi.org/10.1016/j.fuel.2022.124168 (2022).

Nanocatalysts produced by impregnation and calcination transesterified soybean oil to biodiesel with 100 wt% yield. 通过浸渍和煅烧制备了纳米催化剂用于催化豆油酯交换制备生物柴油,产率高达100 wt%。

高炉粉尘制备双功能Na-Fe-Ca纳米催化剂用于生物柴油合成

最近,王一同博士(华北理工大学冶金与能源学院副教授)和方真教授在国际学术期刊Fuel(IF: 6.609,Q1)发表题为“高炉粉尘制备双功能Na-Fe-Ca纳米催化剂用于生物柴油合成”的研究性论文。

利用Na2CO3和CaCO3水溶液分别湿法浸渍高炉粉尘,于500 ℃和600 oC高温活化制备纳米催化剂(Na-BFD500和Ca-BFD600),用于催化豆油制备生物柴油。催化剂经高温煅烧后,CaCO3、Na2CO3和Fe2O3晶体转变为纳米NaFeO2(29.9 nm)、Ca2Fe2O5(10.5 nm)、CaO(100.1 nm)和Ca2Fe2O5(50 nm)晶体,表现出优异的催化活性和可循环利用特性。Na-BFD500催化豆油制备生物柴油的产率达到100.0 wt%,循环16次后仍可获得95.8 wt%的产率,而Ca-BFD600催化豆油制备生物柴油的产率达到98.3 wt%,循环7次后仍可获得94.1 wt%的产率。该研究为工业固体废物用于生物柴油制备提供了新思路。详情可见:

YT Wang, XM Wang, D Gao, FP Wang, YN Zeng, JG Li*, LQ Jiang, Q Yu, R Ji, LL Kang, YJ Wang, Zhen Fang*, Efficient Production of Biodiesel at Low Temperature Using Highly Active Bifunctional Na-Fe-Ca Nanocatalyst from Blast Furnace Waste, Fuel (IF 6.6), 322, 124168, https://doi.org/10.1016/j.fuel.2022.124168 (2022).